- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Horse Rider

-

Application:

-

plastic recycling

-

Production Capacity (kg/h):

-

100 - 3000

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

base on model

-

Power (kW):

-

55KW-110kw

-

Weight (T):

-

20

-

Capacity:

-

200-2000kg/h

-

Color:

-

Optional

-

plastic waste recycling machine:

-

plastic recycler machine

-

plastic recycl machine:

-

plastic recycling machine

-

plastic recycling machinery:

-

plastic recycling machines

-

recycling machine:

-

PET bottle waste recycling plant

-

waste recycling plant:

-

plastic recyclable

-

pet recycling machine,:

-

pet recycle machin

-

Marketing Type:

-

New Product 2020

Quick Details

-

Machine Type:

-

PET Bottle Washing Line

-

Max.Production Capacity (kg/h):

-

3000

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Horse Rider

-

Application:

-

plastic recycling

-

Production Capacity (kg/h):

-

100 - 3000

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

base on model

-

Power (kW):

-

55KW-110kw

-

Weight (T):

-

20

-

Capacity:

-

200-2000kg/h

-

Color:

-

Optional

-

plastic waste recycling machine:

-

plastic recycler machine

-

plastic recycl machine:

-

plastic recycling machine

-

plastic recycling machinery:

-

plastic recycling machines

-

recycling machine:

-

PET bottle waste recycling plant

-

waste recycling plant:

-

plastic recyclable

-

pet recycling machine,:

-

pet recycle machin

-

Marketing Type:

-

New Product 2020

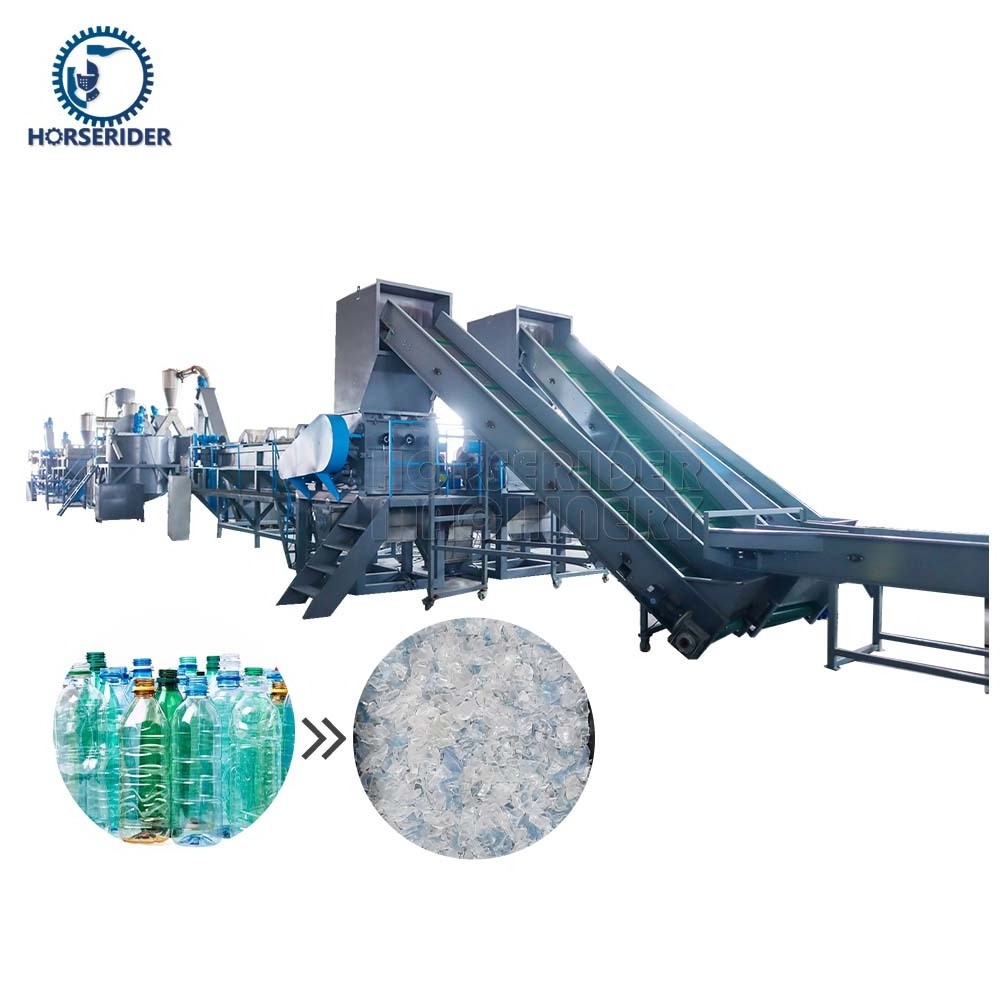

pet flakes hot washing machine

plastic waste recycling machine recycled pet machine /pet recycling plant

It is mainly for PET materials' washing and cleaning. PVC and some other plastics are also can be washed by this line. The whole line is fully automatic and it has characteristics of high efficiency, low noise and easy operation.

It adopts hot water washing to get good quality. Various output capacities can be chosen: 150kg/h 300KG/H, 500-600kg/h, 1000kg/h, 1500kg/h 2000kg/h and 2500kg/h

The recycling line can easily crush, wash and pelletize wasted plastic products from beginning to finished products. Waste and dirty agricultural films and Waste packing material or rigid plastics can be treated step by step by this machine

Work flow of recycled pet machine

Conveying PET bottle→lable remover→ manual sorting table →crusher→screw loader →Hot washer→screw loader→high speed friction washer→screw loader→floating washer→screw loader→spray washer → dewater machine → pipe line dryer → label seperator → blower → hopper

|

Model

|

Capacity(kg/h)

|

Length(M)

|

working way

|

|

PET300

|

300

|

25

|

Automatic

|

|

PET500

|

500

|

50

|

Automatic

|

|

PET1000

|

1000

|

65

|

Automatic

|

|

PET1500

|

1500-2000

|

80

|

Automatic

|

|

PET3000

|

3000

|

90

|

Automatic

|

PET recycling plant is designed to decrease the management cost, minimize water, chemical, gas, electrical consumption and man

power, and with largeOutput capacity and qualified end products. Also offer tailor-made solution according to

customers'requirement.

Basic Equipment List and Description

De-baler----Inclined conveyor feed belt----Trommel----Label removing machine----Pre-washer Crusher----Floating washer-Hot washer-----Frictionwasher(low speed and high speed)----Centrifugal drier----Label dust separation----Packing system----Other optional equipments…

Horizontal type de-baler

Materials:bulk density bottle bales≥250kg/m3

Spiral type shaft structure

Barrier strip in Chamber ensures smooth&

frequent materials feeding.

Vertical type de-baler

Materials:bulk density bottle bales c200kg/m3

Feeding belt speed:ABB inverter

Material dom board ensures uniformly feeding

Remove small size of sands, stone, metal, caps and impurity less than 50mm by rotary centrifugal force.

-Inclined belt conveyor:Wastetransportation for collection

-Screen size:50mm to Separate small sizeof impurities

-Special blowing cycloneLabel separate ratio 85-95%

-Teeth type blades:Made by tungsten steelwith copper welded

bottom of the tank uses V-shaped spiral blades to push the submerged material. The water surface is equipped with a drum-type rake

and a floating material outlet. It also plays a role while pushing the floating material forward and the role of friction cleaning

materials. This machine is suitable for the separation and cleaning of all hard/soft floating water and submerged mixed materials.

The material is sorted thoroughly, the cleaning effect is obvious, and the scope of application is wide. The discharge method

depends on the material properties, and common plastics can be used.

The high-speed washing module is composed of two high-speed washing machines in series, equipped with a water circulation system,

which is a vital part of the PET washing process equipment.

It is usually configured after high-temperature hot washing and friction dehydration.

When the material passes through the equipment, it adheres to the first-in first-out principle.

About 2 minutes, the large water volume of 50 cubic meters per hour is circulated and stirred to clean the bottle flakes, which

can efficiently remove the drug residue on the surface of the bottle flakes.

The whiteness of the bottle is a necessary module to ensure that the quality of the flakes reaches the bottle-to-bottle level.

PET fine has an important on the next production of PET flakes. Especially for the production process of PET sheet, the

requirement of PET fine is extremely strict.

Dust-removal equipment can effectively separate more than 97%residual fines, small plastic labels or film in the flakes by taking

advantage of the gravity between flakes and dust, pneumatic vacuum system and the internal structure specially designed.