- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

3phase,380V 50/60Hz

-

Power:

-

15Kw

-

Dimension(L*W*H):

-

3000x950x1400

-

Weight (KG):

-

550

-

Applicable Industries:

-

Electronic Manufacturing

-

Transport:

-

Mesh or Rail

-

Control system:

-

Touch screen

-

Heating Mode:

-

IR(hot air optional)

-

Conveyor Speed:

-

100-3000mm/min

-

Number of heating zones:

-

Up3/ bottom0

-

Bottom Heating:

-

Optional

-

Length of heating Zones:

-

2200mm

-

Number of cooling Zones:

-

1 or 2

-

Warming Time:

-

Approx. 20 minute

-

Power for Warm Up:

-

15kw

Quick Details

-

Type:

-

Drying Oven

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

I.C.T

-

Voltage:

-

3phase,380V 50/60Hz

-

Power:

-

15Kw

-

Dimension(L*W*H):

-

3000x950x1400

-

Weight (KG):

-

550

-

Applicable Industries:

-

Electronic Manufacturing

-

Transport:

-

Mesh or Rail

-

Control system:

-

Touch screen

-

Heating Mode:

-

IR(hot air optional)

-

Conveyor Speed:

-

100-3000mm/min

-

Number of heating zones:

-

Up3/ bottom0

-

Bottom Heating:

-

Optional

-

Length of heating Zones:

-

2200mm

-

Number of cooling Zones:

-

1 or 2

-

Warming Time:

-

Approx. 20 minute

-

Power for Warm Up:

-

15kw

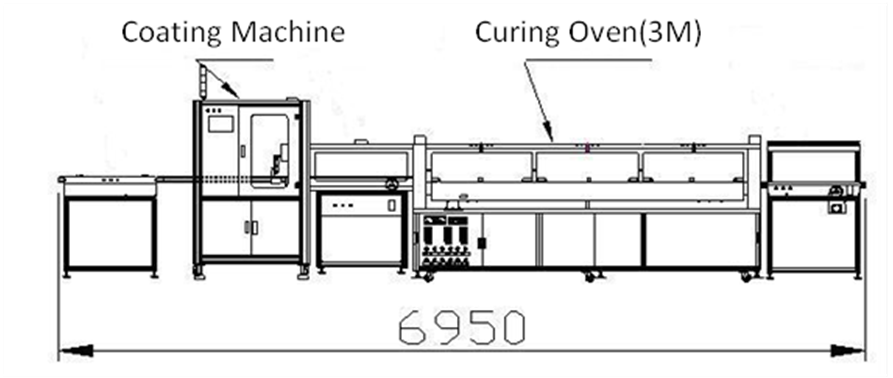

SMT PCBA coating line solution:

(PCBA coating loader+ selective coating machine +coating conveyor + IR curing oven)

2. Continuous surface spraying, automatic detecting initial distance and coated width.

3. Stepper motor reciprocating coating, can be arbitrary set about PCB before and after the offset. Special aluminum alloy orbit and stainless steel conveyor chain.

4. Equipped with a fan-shaped spray glue valve, can be automatically.

5. Rubber valve automatically soak, to prevent clogging.

Features:

2. Continuous surface spraying, automatic detecting initial distance and coated width.

3. Servo motor reciprocating coating, can be arbitrary set about PCB before and after the offset.Special aluminum alloy orbit and stainless steel conveyor chain.

4. Equipped with a fan-shaped spray glue valve, can be automatically.

5. Rubber valve automatically soak, to prevent clogging.

6. Inlet and outlet are equipped with communication socket, can online connection with other machines.

7. Independent paint container barrels

8. Equipped with exhaust gas collection, outfalls.

|

Model

|

PCBA Coating Machine I.C.T - T550

|

|

Dimension

|

L1100*W1300*H1700mm

|

|

Weight

|

Approx.750kg

|

|

PCB Size(mm)

|

50*50 ~ 450*450

|

|

PCB Thickness

|

0.4~6mm

|

|

PCB Warpage

|

<1%

|

|

Transport Height

|

900±20mm

|

|

Transport Direction

|

Left-Right; Right-Left

|

|

Transport Speed

|

Max 3500mm/s

|

|

Air Pressure

|

4.5~6Kg/cm2

|

|

Power Supply

|

AC:220±10%,50/60HZ, 2.5Kw

|

|

Control Method

|

PC Control

|

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner

Q: Are you a trade company or manufacturer?

A: Full SMT machines maufacturer for smt line in China; OEM & ODM service are available.

Q: What is your delivery date?

A: About 35 days after receipt of pay

ment.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Q: What your main customers?

A: Huawei, Foxconn, Vtech, Sumida, Kemet, Vishay, Bosch, Canon, Jabil etc.

Q: Why choose you?

A: Leading SMT Supplier in China; Professional Supplier on Alibaba;

Trade assurance to USD 560,000+; Professional after-sales service team.