- Product Details

- {{item.text}}

Quick Details

-

Dimension:

-

1200*1930*1500mm

-

PCB size:

-

50*50---400*350mm

-

PCB thickness:

-

0.1---6mm

-

Mounting speed:

-

30000--35000 CPH

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

ETON

-

Model Number:

-

RT-1

-

Dimension:

-

1200*1930*1500mm

-

PCB size:

-

50*50---400*350mm

-

PCB thickness:

-

0.1---6mm

-

Mounting speed:

-

30000--35000 CPH

Single module magnetic linear motor multifunction pick and place machine RT-1

Magnetic linear motor multifunctional pick and place machine.

Mounting components: LED, capacitors, resistors, IC, shaped components, etc.

Application: DOB, LED bulb, LED strip, LED tube, lens, Power driver, E lectric board, etc.

Support mounting over 22mm high components, very suitable for DOB mounting.

Electronic feeder feeding system.

Vision alignment flight identification, Mark correction.

Auto-optimization after coordinates generations, etc.

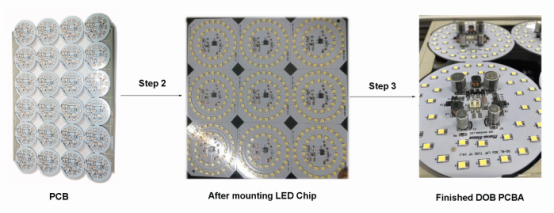

Main process of SMT Line for DOB manufacturing

Step one: Print Solder paste on PCB

Step two: Mounting LED chip and capacitor big components on PCB.

Step three: H eat ing solder paste with PCB to welding together the component with PCB.

Different type of DOB PCBA

The PCBA of Linear bulbs

RT-1 SMT line not only suitable for DOB and bulb , but also suitable for many other products, such as:

|

Number of Heads |

10 |

|

Max Placement Rate |

35000 CPH |

|

Max Tape Feeder Capacity |

32 |

|

PCB Length Width |

Max: 400 *3 5 0mm Min: 5 0* 5 0mm |

|

Component Range |

Smallest Size 0402 |

|

Max Height 22 mm |

|

|

Length |

1200 MM |

|

Width |

1930 MM |

|

Height |

1 7 5 0MM |

|

Total Weight |

2 2 0 0 KG |

Step one: Using Solder printing machine to Print Solder paste on PCB .

Step two: Using pick and place machine to m ount LED chip and capacitor big components on PCB.

Step three: Using reflow oven to h eat solder paste with PCB to welding together the component with PCB.

============================================

Q1: Are you a manufacturer or trading company?

A1: manufacturer. We have our own industrial park.

Q2: What about the shipping methods?

A2: A variety of transportation methods for you to choose. By sea, air and road.

Q3:What’s your delivery time?

A3:Usually 30 days after deposit, if we have inventory, the time can be brought forward.

Q4:How can you make sure we will receive the machine with high quality?

A4: Our team will inspect each batch of machine before delivery, we have certificates of CE,CCC,SIRA.

Q5:How is your service?

l Our technicians can come to train and install machines, etc.

l We regularly visit customers to understand customer usage and collect customer opinions.

l We regularly provide customers with the latest production technology and equipment information.

Q6:Machine is easy to operate?

A6:Machine is easy to operate,usually 3 to 5 days training of operating is enough.

Add: If you have any other questions, please do not hesitate to contact us, we will serve you wholeheartedly 24 hours!

===================================================================