Keep the

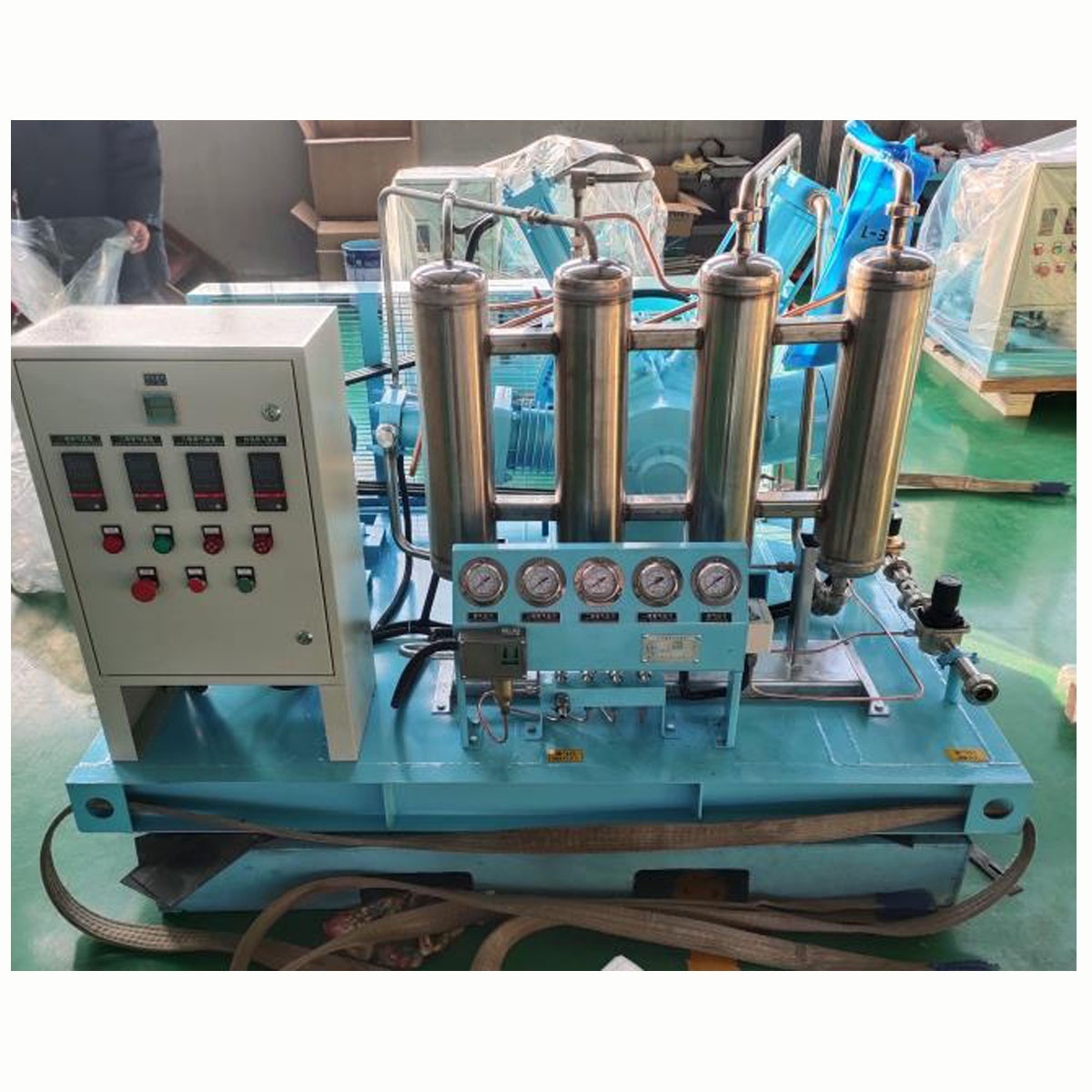

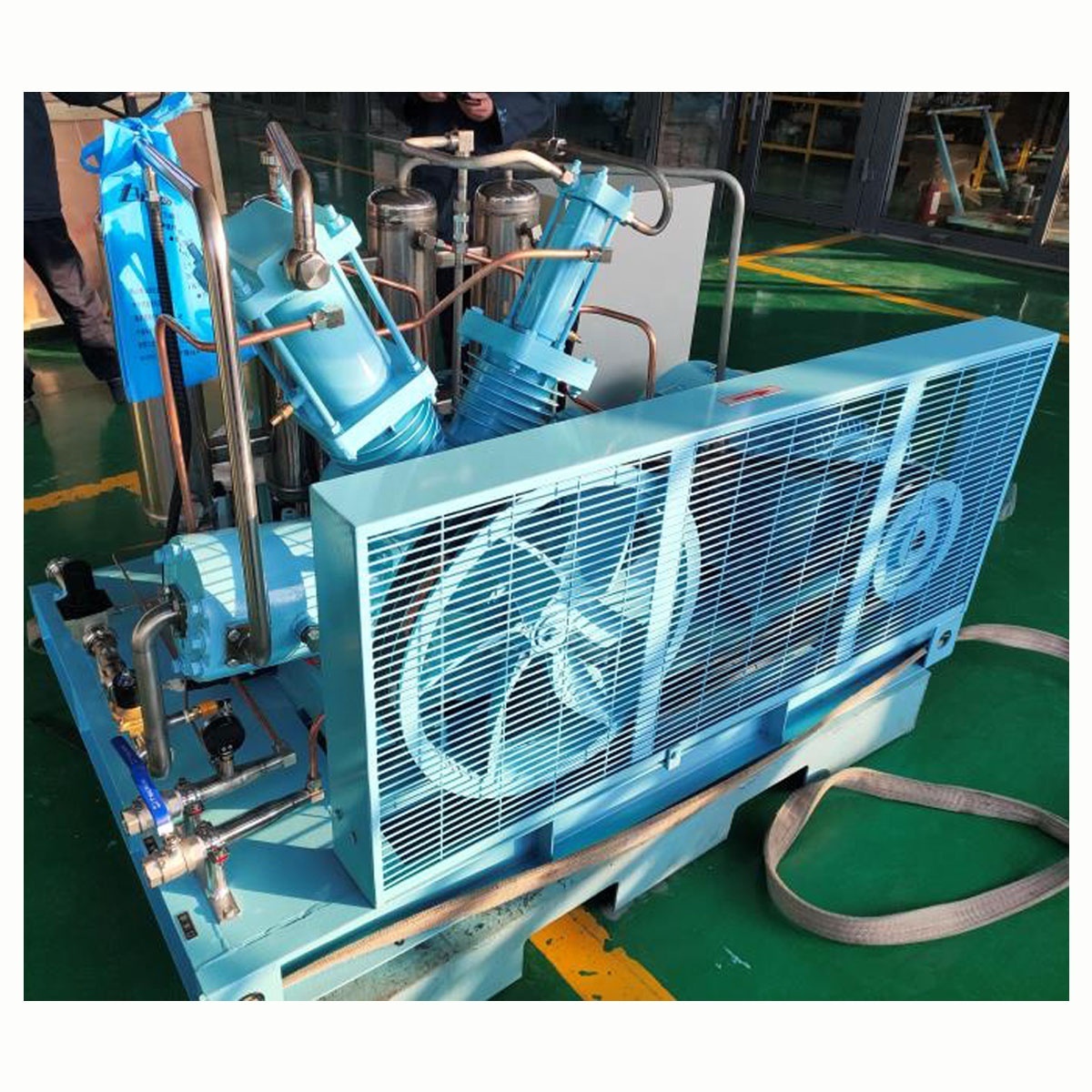

Oxygen Cylinder Filling Station

clean, observe diligently, deal with abnormal situation in time, do not let the compressor work with failure. Compressor disassembly maintenance or replacement parts must be carried out by experienced maintenance personnel or the production plant to avoid unnecessary losses.

It is necessary to check whether the voltage and current deviation is too large to prevent over-voltage or under-voltage operation and damage to the motor.

During the normal operation of the compressor, it is easy not to disconnect the power supply. In case of power failure or power failure for other reasons, the power supply must be cut off to stop the work.

If any abnormal sound is found during the operation of the compressor, it should be stopped immediately for inspection.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/360V/380V/415V/440V 50/60HZ, 220V/360V/380V/415V/440V 50/60HZ

-

Dimension(L*W*H):

-

1650*950*1470mm

-

Weight:

-

960kg

-

Working Pressure:

-

4bar

-

Air capacity:

-

20 Nm3/h

-

Flow rate:

-

5~300nm3/h

-

Inlet Pressure:

-

4bar

-

Outlet Pressure:

-

150~300bar

-

Number of Compression Stage:

-

4

-

Number of Cylinder:

-

4

-

Instructure:

-

Oil-free Lubrication Vertical

-

Cooling Way:

-

Air/Water

-

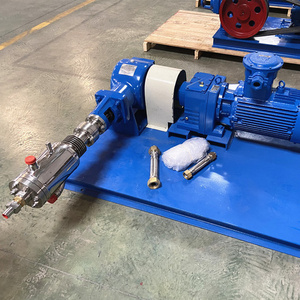

Drive Way:

-

Belt

-

Standard:

-

ISO9001/13485/CE

Quick Details

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

Cape-Golden

-

Model Number:

-

GOW-20/4-150

-

Voltage:

-

220V/360V/380V/415V/440V 50/60HZ, 220V/360V/380V/415V/440V 50/60HZ

-

Dimension(L*W*H):

-

1650*950*1470mm

-

Weight:

-

960kg

-

Working Pressure:

-

4bar

-

Air capacity:

-

20 Nm3/h

-

Flow rate:

-

5~300nm3/h

-

Inlet Pressure:

-

4bar

-

Outlet Pressure:

-

150~300bar

-

Number of Compression Stage:

-

4

-

Number of Cylinder:

-

4

-

Instructure:

-

Oil-free Lubrication Vertical

-

Cooling Way:

-

Air/Water

-

Drive Way:

-

Belt

-

Standard:

-

ISO9001/13485/CE

Oxygen Cylinder Filling Station of Skid Type

Introduction

Cape-Golden

Oxygen Cylinder Filling Station

is no liquid lubricant in the body and no liquid lubricant in the crankcase supporting the crankshaft. Piston ring and guide ring is made of high quality modified PTFE with self-lubricating performance. The main parts of stainless steel and copper, aluminum and other material is not easy to produce sparks, all bearings with seals prevent loss of grease, the high pressure

Oxygen Cylinder Filling Station

lubrication system, the movement of the friction pair of grease are the antioxidant of

Oxygen Cylinder Filling Station

special grease.

Product Specification

|

Model

|

Capacity/

Flow Rate

|

Inlet Pressure

|

Discharge Pressure

|

Power

|

Weight

|

Dimension(L*W*H)

|

|

GOW-3/4-150

|

3m³/h

|

3-4bar

|

150bar

|

3KW

|

140kg

|

850*640*680mm

|

|

GOW-5/4-150

|

5m³/h

|

3-4bar

|

150bar

|

3.5KW

|

320kg

|

1000*800*1100mm

|

|

GOW-10/4-150

|

10m³/h

|

3-4bar

|

150bar

|

5KW

|

320kg

|

1000*800*1100mm

|

|

GOW-15/4-150

|

15m³/h

|

3-4bar

|

150bar

|

11.5KW

|

960kg

|

1650*950*1470mm

|

|

GOW-20/4-150

|

20m³/h

|

3-4bar

|

150bar

|

12KW

|

960kg

|

1650*950*1470mm

|

|

GOW-30/4-150

|

30m³/h

|

3-4bar

|

150bar

|

13.5KW

|

960kg

|

1650*950*1470mm

|

|

GOW-40/4-150

|

40m³/h

|

3-4bar

|

150bar

|

15KW

|

960kg

|

1650*950*1470mm

|

|

GOW-50/4-150

|

50m³/h

|

3-4bar

|

150bar

|

17KW

|

960kg

|

1650*950*1470mm

|

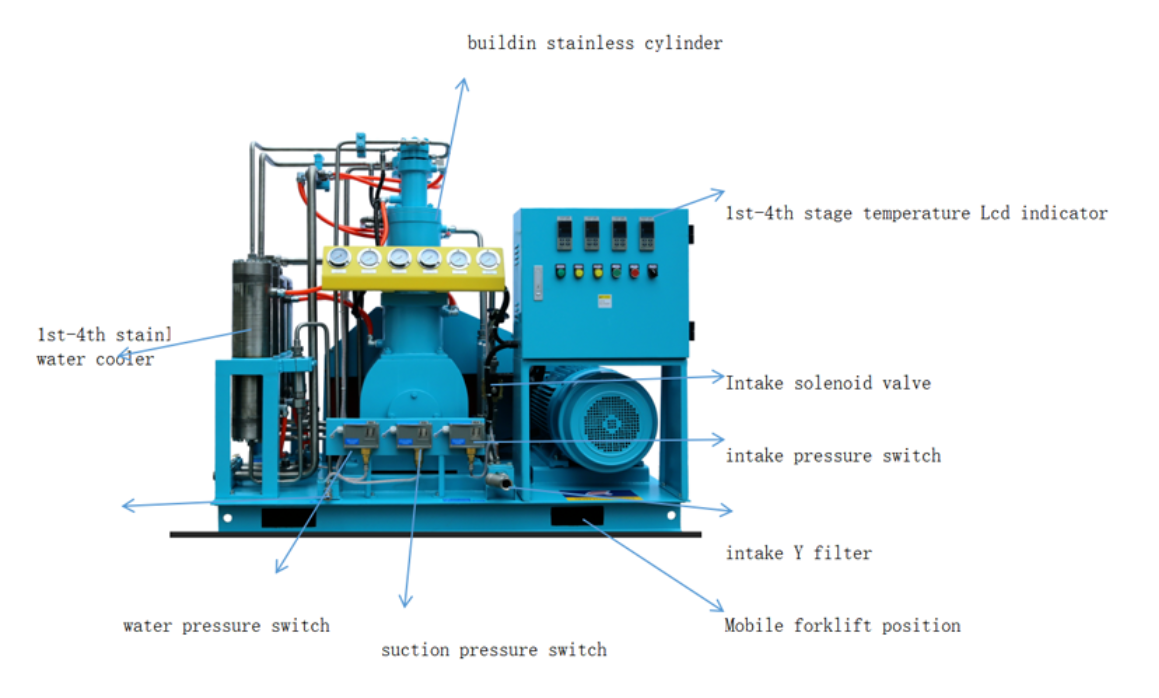

Product Configuration

Oxygen Compressor Control Mode

Oxygen Cylinder Filling Station

adopts inlet, exhaust pressure switch + inlet and exhaust solenoid valve automatic control.

The Oxygen Cylinder Filling Station 's electrical control loop is connected with the inlet and exhaust pressure switch, in which the inlet pressure switch is normally open, used for the protection of shutdown when the inlet pressure is too low.

The exhaust pressure switch is normally closed, which is used for stopping protection when the exhaust pressure is too high. The specific control principle is: when the air source pressure reaches the upper limit of the intake pressure switch set value, the pressure switch is closed, press the start button at this time, the motor runs, the intake electromagnetic power is opened, the exhaust solenoid valve is disconnected, and the fan starts running and the compressor works normally.

When the exhaust pressure rises to the upper limit of the exhaust pressure switch set value, the exhaust pressure switch acts and the machine stops running. At the same time, the inlet solenoid valve is disconnected and closed.

When the exhaust pressure drops to the lower limit set by the exhaust pressure switch, the exhaust pressure switch is closed, and the machine continues to operate. The oxygen bottling machine needs to be manually reset and run. When the air source pressure falls to the lower limit of the intake pressure switch set value, the intake pressure switch is disconnected, and the machine stops running in standby state.

When the air source pressure is restored to the upper limit of the inlet pressure switch set value, the inlet pressure switch is closed and the machine continues to run.

Temperature protection, each stage of the compressor is equipped with temperature sensor, when the exhaust temperature of a stage is too high, the alarm will stop.

The Oxygen Cylinder Filling Station 's electrical control loop is connected with the inlet and exhaust pressure switch, in which the inlet pressure switch is normally open, used for the protection of shutdown when the inlet pressure is too low.

The exhaust pressure switch is normally closed, which is used for stopping protection when the exhaust pressure is too high. The specific control principle is: when the air source pressure reaches the upper limit of the intake pressure switch set value, the pressure switch is closed, press the start button at this time, the motor runs, the intake electromagnetic power is opened, the exhaust solenoid valve is disconnected, and the fan starts running and the compressor works normally.

When the exhaust pressure rises to the upper limit of the exhaust pressure switch set value, the exhaust pressure switch acts and the machine stops running. At the same time, the inlet solenoid valve is disconnected and closed.

When the exhaust pressure drops to the lower limit set by the exhaust pressure switch, the exhaust pressure switch is closed, and the machine continues to operate. The oxygen bottling machine needs to be manually reset and run. When the air source pressure falls to the lower limit of the intake pressure switch set value, the intake pressure switch is disconnected, and the machine stops running in standby state.

When the air source pressure is restored to the upper limit of the inlet pressure switch set value, the inlet pressure switch is closed and the machine continues to run.

Temperature protection, each stage of the compressor is equipped with temperature sensor, when the exhaust temperature of a stage is too high, the alarm will stop.

Operation, Running and Daily Maintenance

Show

Hot Searches