- Product Details

- {{item.text}}

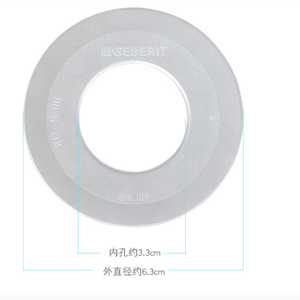

Quick Details

-

Model Number:

-

products024

-

Business Type:

-

Manufacturer/OEM Factory

-

Shaping Mode:

-

Plastic Injection Mould

-

Product Material:

-

liquid silicone (LSR)

-

Color:

-

white,Black,clear, red, blue, or according to customer's requirements.

Quick Details

-

Processing Service:

-

Moulding, Cutting

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DERUI

-

Model Number:

-

products024

-

Business Type:

-

Manufacturer/OEM Factory

-

Shaping Mode:

-

Plastic Injection Mould

-

Product Material:

-

liquid silicone (LSR)

-

Color:

-

white,Black,clear, red, blue, or according to customer's requirements.

![]()

![]()

| DESCRIPTION OF PRODUCT |

|

Company Name |

Derui Silicone Technology (Guangzhou) Co.,Ltd. |

|

Business Type |

Manufacturer/OEM Factory |

|

Process |

Injection molding |

| Plastic Materials | Liquid Silicone Rubber (LSR), ABS,PC,PP,PS, PVC , PE,PA , etc. |

|

Colors Available |

white, Black, clear, red, blue, or according to customer's requirements. |

|

Mould Life |

500,000 Times Shots |

|

Mould Cavity |

Single cavity or multi cavity |

| Advantages | Competitive price & Fast Delivery & Good quality |

|

Runner System |

Hot runner and cold runner |

|

Advanced Testing Equipment |

Prismo 3D equipment for inspection, 2D testers and other |

|

Mould Precision |

+/-0.01mm ; |

| File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG , DWG, AI, etc. |

|

Quality Management |

ISO9001, ISO13485 |

| Inspection | IQC, IPQC,FQC,QA |

|

Products Applications |

Medical instrument parts and medical disposables, consumer electronics, sports, beauty and personal care products, baby's products, Kitchen and bathroom products, small parts for automobile, aviation and aerospace equipments , etc. |

| Prototyping |

Drawings and quantities will be needed for a detailed quotation. Free Sample will be offered for approval after PO |

| Service |

Warm and quick response service provided by the professional Export Sales Team with many years' experience in handling exports to the US, Europe, Japan and other countries and regions. |

| OUR SERVICE |

1. Product design and development, both ODM and OEM.

2. Drawing re-construction. (Simple design is free of charge)

3. Mold setup and trial shot.

4. Liquid silicone and Injection molding for the plastic parts.

5. Mass production. (price will be very cheap with large quantity)

![]()

![]()

| PRODUCT CASES |

Derui Silicone Technology (Guangzhou) Co.,Ltd . is located in Panyu District, Guangzhou City, China. Focusing on the R&D, design, injection molding, OEM production and sales of liquid silicone products and plastic products. We have passed ISO9001 and ISO13485 international certification. With over 15 years of experience in the industry and extensive experience in silicone/plastic mold design, the designed molds have a wide range of applications, including baby products, medical products, kitchen and bathroom products, electronic 3C products, new energy vehicle products, diving mask products, and silicone insulator products.

| OUR FACTORY |

| CERTIFICATE |

| FAQ |

Q1.How to have my components quoted ?

A1: Please contact us via TradeManager or Email and send us your drawings inclusive of 2D and 3D (.STEP or .IGE file) and detail requirements. We are pleased to sign NDA with you if you prefer. Then our engineering team will work on them and submit competitive quotation to you.

Q2.What is the lead time for tooling and samples fabrication?

A2: The exact lead time depends on your parts specification.

The normal lead time is

30~

45 days for tooling fabrication and samples.

If the tooling is not required, the lead time for samples is 15 days normally.

Q

3

.How to ship the samples and production order ?

A

3

: We will normally ship samples via DHL, UPS or FedEX via our cooperated forwarder or freight collect. For the shipping of production order, it will be by sea or by air

Q

4

.Can I have prototypes for testing before tooling ?

A

4

: Yes, our factory have team to support prototypes with machining process to fabricate them for your testing.

Q5.How to ensure the quality of parts?

A5: Firstly, our team will inspect all incoming material. QC team will inspect parts while production and finished products, then submit Quality Inspection Report together with samples and production order.

Q6.What Certificate do you have?

A5: We have certified with ISO 9001 and ISO 13485.