- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

170 mm

-

Width of Working Table (mm):

-

1250 mm

-

Place of Origin:

-

Jinan

-

Weight (KG):

-

8000

-

Motor Power (kw):

-

15 kw

-

Marketing Type:

-

Hot Product

-

Power:

-

Hydraulic

-

Product name:

-

CNC Press Brake Machine

-

CNC or not:

-

CNC BendingMachine

-

Voltage:

-

220V/380V/415V/440V/customized

-

Numberof axes Standard 10-axis:

-

11/12 OPTION

-

Bending thickness:

-

1.5MM

Quick Details

-

Machine Type:

-

Roller-Bending Machine

-

Length of Working Table (mm):

-

1600

-

Slider Stroke (mm):

-

1500 mm

-

Throat Depth (mm):

-

170 mm

-

Width of Working Table (mm):

-

1250 mm

-

Place of Origin:

-

Jinan

-

Weight (KG):

-

8000

-

Motor Power (kw):

-

15 kw

-

Marketing Type:

-

Hot Product

-

Power:

-

Hydraulic

-

Product name:

-

CNC Press Brake Machine

-

CNC or not:

-

CNC BendingMachine

-

Voltage:

-

220V/380V/415V/440V/customized

-

Numberof axes Standard 10-axis:

-

11/12 OPTION

-

Bending thickness:

-

1.5MM

Product Description

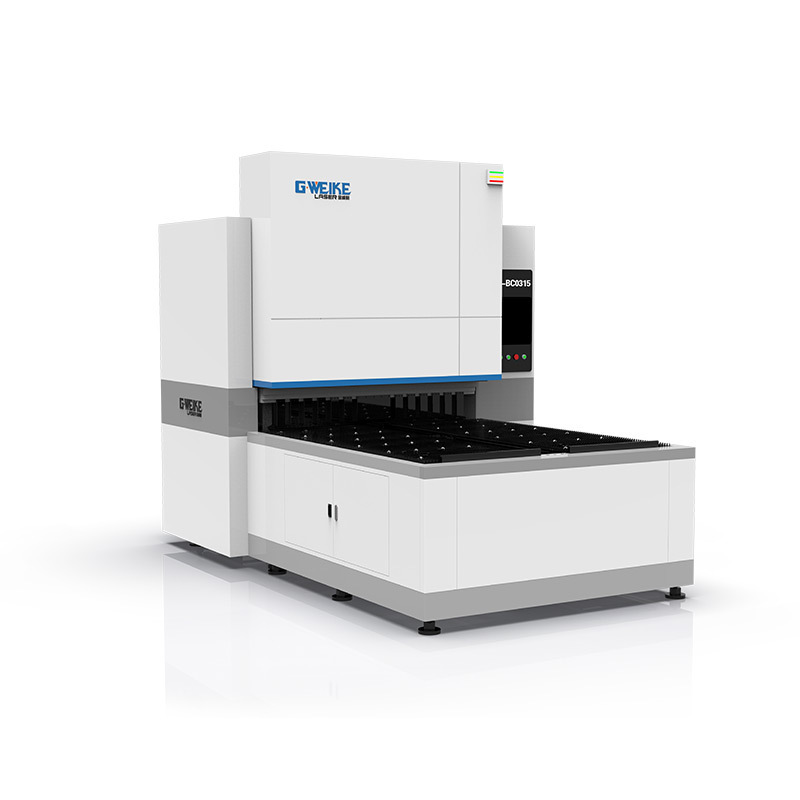

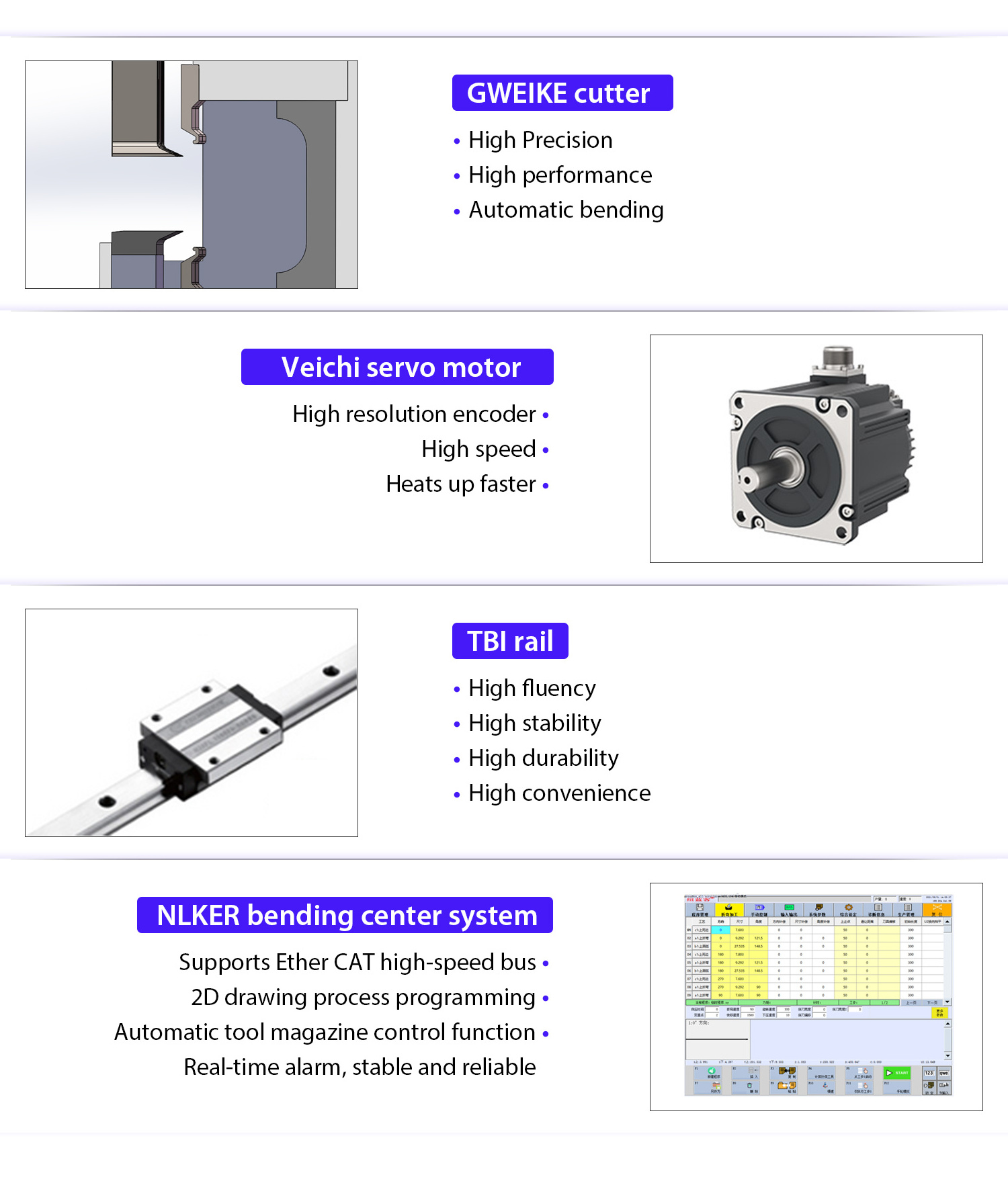

1500mm CNC Panel Bender Sheet Metal Folding Machine Automatic Bending Center

Main Features:

The flexible bending center focuses on solving various complicated sheet metal and bending problems in metal forming. Through multi-axis concurrent linkage, sheet metal operations are automatically completed, and the dependence on molds and labor is resolved from a technical perspective, which effectively improves production efficiency and reduces production costs.

Easily realize the arc, press dead edge, back shape, closed shape and other complex sheet metal bending requirements.

The flexible bending center can be widely used in the field of steel cabinet shells (file cabinets, tool cabinets, outer shields,

electrical cabinets, communication cabinets, gas cabinets, water meter cabinets...), kitchen utensils (refrigerators, air

conditioners, stoves...) , Furniture, ventilation, refrigeration, purification, door industry, decoration, elevator and other

related metal forming fields

The flexible bending center focuses on solving various complicated sheet metal and bending problems in metal forming. Through multi-axis concurrent linkage, sheet metal operations are automatically completed, and the dependence on molds and labor is resolved from a technical perspective, which effectively improves production efficiency and reduces production costs.

Easily realize the arc, press dead edge, back shape, closed shape and other complex sheet metal bending requirements.

The flexible bending center can be widely used in the field of steel cabinet shells (file cabinets, tool cabinets, outer shields,

electrical cabinets, communication cabinets, gas cabinets, water meter cabinets...), kitchen utensils (refrigerators, air

conditioners, stoves...) , Furniture, ventilation, refrigeration, purification, door industry, decoration, elevator and other

related metal forming fields

Specification

|

item

|

value

|

|

Slider Stroke (mm)

|

1500mm

|

|

Automatic Level

|

Fully Automatic

|

|

Throat Depth (mm)

|

170mm

|

|

Machine Type

|

Roller-Bending Machine

|

|

Length of Working Table (mm)

|

1600

|

|

Width of Working Table (mm)

|

1250mm

|

|

Dimension

|

3780*2420*2675mm

|

|

Condition

|

New

|

|

Material / Metal Processed

|

Brass / Copper, Stainless Steel, Carbon steel, Aluminum

|

|

Automation

|

Automatic

|

|

Weight (KG)

|

8000

|

|

Motor Power (kw)

|

15kw

|

|

Key Selling Points

|

Automatic

|

|

Warranty

|

1 Year

|

|

Applicable Industries

|

Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Construction works , Energy & Mining, Advertising Company

|

|

Showroom Location

|

UAE

|

|

Marketing Type

|

Hot Product

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

Bearing, Gear

|

|

Power

|

Hydraulic

|

|

Product name

|

CNC Press Brake Machine

|

|

CNC or not

|

CNC BendingMachine

|

|

Voltage

|

220V/380V/415V/440V/customized

|

|

Numberof axes Standard 10-axis

|

11/12 OPTION

|

|

Bending thickness

|

1.5MM

|

Certificates

Packing & Delivery

1. Anti-collision package edge: All parts of the machine are covered with some soft materials, mainly the use of pearl wool.

2. Fumigation wooden box.

3. Whole film packaging machine, to avoid all damage that may occur during delivery.

4.Wooden box at the bottom of a solid iron socket for easy handling

1500mm CNC Panel Bender Sheet Metal Folding Machine Automatic Bending Center

Hot Searches