- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTL

-

Voltage:

-

according to customer

-

Dimension(L*W*H):

-

920*800*1258mm

-

Weight (KG):

-

16000 kg

-

After Warranty Service:

-

Online Technical Support

-

Key words:

-

Brick Making Mahcine

-

Certification:

-

ISO 9001

-

item:

-

aac block making machine production line

-

motor:

-

Siemens Motor

Quick Details

-

Type:

-

Autoclaved aerated concrete block (AAC)

-

Brick Raw Material:

-

sand,cement,fly ash,concrete

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTL

-

Voltage:

-

according to customer

-

Dimension(L*W*H):

-

920*800*1258mm

-

Weight (KG):

-

16000 kg

-

After Warranty Service:

-

Online Technical Support

-

Key words:

-

Brick Making Mahcine

-

Certification:

-

ISO 9001

-

item:

-

aac block making machine production line

-

motor:

-

Siemens Motor

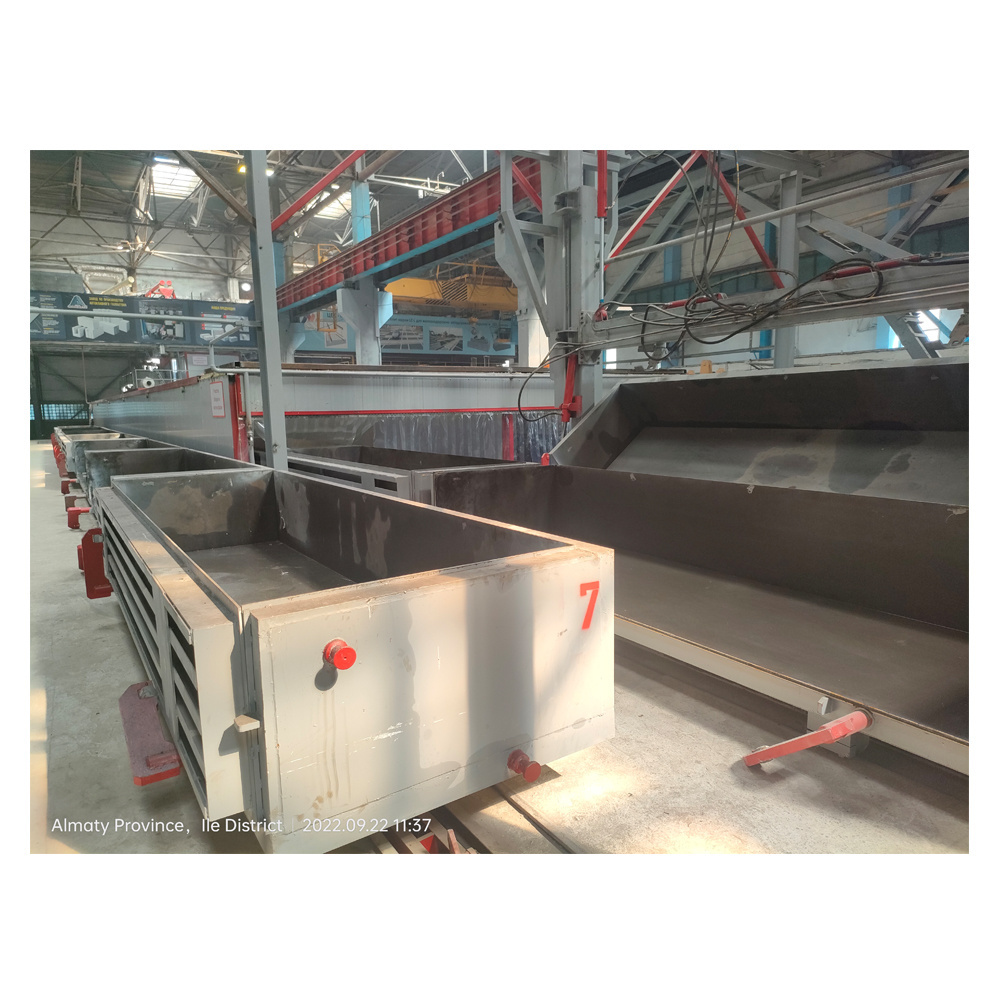

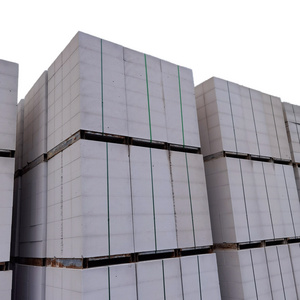

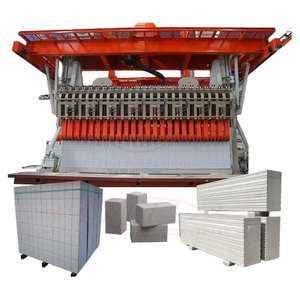

Factory sell Germany Technology AAC Block Cutting Machinery brick production Equipment for russia

AAC block manufacturing machine

Aerated concrete block equipment (gas filling block equipment) is a new type of building materials machinery equipment. and we can supply complete set of autoclaved aerated concrete plant with 10 000m3, 2 0 000m3, 50 000m3, 100 000m3, 150 000m3, 200 000m3, 250 000m3, 300 000m3 capacity annually, including plant design, equipments installation, technical instruction, personal training, etc, and also can design and manufacture as per clients' requirement.

1. Raw material: Store the fly-ash (tailings etc), lime and gypsum after milling to the needed fineness (200 mesh)

2. Mixing the fly-ash, cement, lime, gypsum and water in the pot after batching.

3. Promote the slurry temperature to 40-50 degree by steam, and mill with aluminum powder for 1min.

4. Pour the slurry into the mould, and still in the curing room for frothing in 2-2.5h.

5. Cut it in to needed size by the cutter after the slurry approach the cutting intensity, and place the block on the trolley.

6. Autoclaved curing after the trolley enter into the autoclave (vacuum, rise the pressure, keep the pressure, reduce the pressure),keeping the constant pressure 1.2MPa. The whole process needs about 12h.

7. The products out of the autoclave are placed in a stack. We can recycle the scrap and the waste water from the whole production.

2. Raw material for AAC block making machine/ aac plant/aac production line

AAC Aerated concrete is the lightweight artificial stone, adopting the calcareous material and the siliceous material as components, forming the porous structures by the way of chemical gas generation, and obtaining the intensity after autoclaved curing. The calcareous material is mainly lime and cement, the siliceous material generally is industrial waste in China, such as fly-ash, tailings etc, or quartz sand.

3. Dosing & mixing & pouring of AAC

The metered slurry pours into the pouring & mixing machine according to order, and at same time, the dumping device of electronic scale discharges the metered lime and cement powder to pouring and mixing machine. Then the slurry in Slurrying tank after being mixed will be poured into mold box below the Slurrying tank

4. Cutting &marshalling of AAC

After the base reaches to certain hardness for cutting through static stop curing, the overturning crane on cutting and overturning vehicle (10t) hoists and overturns the base to the cutting dolly and demoulds, which overturns the base 90 degrees. Cutting dolly moves to finish transverse and vertical cutting.

The cut base with side plate will be conveyed by marshalling crane to the steam curing dolly and then pulled into autoclaves to steam curing.

5. Steam curing & finished product of AAC

The steam curing time in constant pressure is 4 to 10 hours with the steam pressure 1.3Mpa and temperature around 190°C. Finished products after steam curing are dragged out from autoclave by slow moving hoist, and be lifted by crane to the transport vehicles

6. Retuning, assembling and oiling on Base (side) plate

After conveying the finished products, the bottom (and side) plate on steam curing dolly with the dolly are lifted to lane for returning.

| Annual Capacity ( 300days ) | Daily Capacity | Cycle Time |

| 50,000m ³ /year | 166 m ³ /day | 8 hours |

| 100,000m ³ /year | 333m ³ /day | 8 hours |

| 150,000m ³ /year | 500m ³ /day | 8 hours |

| 200,000m³/year | 666m ³ /day | 8 hours |

| 300,000m³/year | 1000m ³ /day | 8 hours |

water conservancy and other departments.

industries. It can be divided into dry and wet grinding methods. Depending on the method of discharge, it can be divided into two

types: grid type and overflow type

according to a certain ratio, uniformly mixing, fully reacting, and timely injecting the mixed slurry into the mold

size.

Cutting process

Using reversal crane carry the mould and block to demould on cutting cart. The cutting cart will take the block to level cutting

machine

trolley into autoclave to steam, it need 8-12 hours.