- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

2000 r.p.m

-

Max. Weight of Workpiece(kg):

-

4500

-

Width of bed (mm):

-

40 mm

-

Spindle Motor Power(kW):

-

18

-

Max. Turned Length (mm):

-

430

-

Travel (X Axis)(mm):

-

300 mm

-

Travel (Z Axis)(mm):

-

450 mm

-

Positioning Accuracy (mm):

-

0.01

-

Repeatability (X/Y/Z) (mm):

-

0.003

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

1590*2670*2542mm

-

Brand Name:

-

jianha

-

Model Number:

-

VTC60

-

Voltage:

-

380

-

Weight (KG):

-

4500

-

Max spindle speed:

-

2800/2000rpm

-

Guideway:

-

Taiwan linear guide ways

-

Tool shank:

-

25x25mm

-

Spindle nose:

-

A2-6/A2-8

-

Chuck size:

-

10"/12" Taiwan hydraulic chuck

-

Max turning height:

-

420/430/600mm

-

Turret Type:

-

8-station Taiwan hydraulic turret

-

Control system:

-

SIEMENS GSK FANUC (optional)

-

Max cutting diameter:

-

320/500/600mm

-

Certification:

-

ISO9001, CE, SGS

Quick Details

-

Type:

-

VERTICAL

-

Max. Length of Workpiece (mm):

-

430

-

Year:

-

2021

-

Max. Spindle Speed (r.p.m):

-

2000 r.p.m

-

Max. Weight of Workpiece(kg):

-

4500

-

Width of bed (mm):

-

40 mm

-

Spindle Motor Power(kW):

-

18

-

Max. Turned Length (mm):

-

430

-

Travel (X Axis)(mm):

-

300 mm

-

Travel (Z Axis)(mm):

-

450 mm

-

Positioning Accuracy (mm):

-

0.01

-

Repeatability (X/Y/Z) (mm):

-

0.003

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

1590*2670*2542mm

-

Brand Name:

-

jianha

-

Model Number:

-

VTC60

-

Voltage:

-

380

-

Weight (KG):

-

4500

-

Max spindle speed:

-

2800/2000rpm

-

Guideway:

-

Taiwan linear guide ways

-

Tool shank:

-

25x25mm

-

Spindle nose:

-

A2-6/A2-8

-

Chuck size:

-

10"/12" Taiwan hydraulic chuck

-

Max turning height:

-

420/430/600mm

-

Turret Type:

-

8-station Taiwan hydraulic turret

-

Control system:

-

SIEMENS GSK FANUC (optional)

-

Max cutting diameter:

-

320/500/600mm

-

Certification:

-

ISO9001, CE, SGS

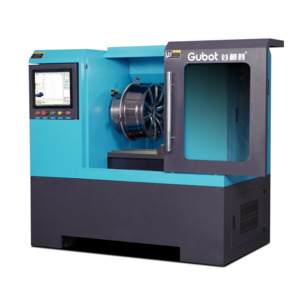

Product Overview

High-precision CNC vertical lathe.

Main Functions:

VTC60 machine tool is a kind of automation numerical control processing machine tool, applied to machining the internal and

external cylinder, conical surface, end face, grooving and chamfering regarding components, and particularly suitable for

machining automobile hub, discs and other components.

Main Features:

1. The machine tool is of roller type linear slide rail, with ultrahigh rigidity and overload capacity, substantially improving

positioning accuracy and bearing capacity in regard to vertical and horizontal feed movement.

2. The machine tool spindle belt pulley is connected with that of spindle numerical control servo motor through belt, equipped

with 22Kw motor for infinitely variable speed of wide range, satisfying different spindle speed required for parts rough machining

and finish machining.

3. Both the vertical and horizontal feed is controlled by servo motor automatically. The vertical direction setting Balance weight

structure greatly extend the life cycle of lead screw

4. The machine tool rest is of horizontal or vertical multi-station numerical control structure, shortening tool changing time,

and greatly improving work efficiency.

5. The upper end of spindle may be equipped with disc type workbench or hydraulic chuck based on user's requirements. The angling

cylinder (single-piston and double-piston) is applicable to the lower end of the spindle. For the control of the workpiece and the

hydraulic chuck

6. This machine tool may be equipped with domestic numerical control system of HNC, KND, GREAT and GSK, also imported system

optionally by users.

VTC60 machine tool is a kind of automation numerical control processing machine tool, applied to machining the internal and

external cylinder, conical surface, end face, grooving and chamfering regarding components, and particularly suitable for

machining automobile hub, discs and other components.

Main Features:

1. The machine tool is of roller type linear slide rail, with ultrahigh rigidity and overload capacity, substantially improving

positioning accuracy and bearing capacity in regard to vertical and horizontal feed movement.

2. The machine tool spindle belt pulley is connected with that of spindle numerical control servo motor through belt, equipped

with 22Kw motor for infinitely variable speed of wide range, satisfying different spindle speed required for parts rough machining

and finish machining.

3. Both the vertical and horizontal feed is controlled by servo motor automatically. The vertical direction setting Balance weight

structure greatly extend the life cycle of lead screw

4. The machine tool rest is of horizontal or vertical multi-station numerical control structure, shortening tool changing time,

and greatly improving work efficiency.

5. The upper end of spindle may be equipped with disc type workbench or hydraulic chuck based on user's requirements. The angling

cylinder (single-piston and double-piston) is applicable to the lower end of the spindle. For the control of the workpiece and the

hydraulic chuck

6. This machine tool may be equipped with domestic numerical control system of HNC, KND, GREAT and GSK, also imported system

optionally by users.

PRODUCT SPECIFICATIONS

|

arameter

|

UNIT

|

VTC450

|

VTC60

|

VTC70

|

VTC80

|

VTC100

|

|

Max.Swing diameter

|

mm

|

500

|

650

|

700

|

800

|

1000

|

|

Spindle speed No.

|

|

|

|

|

|

|

|

Spindle speed

|

rpm

|

100~1500

|

100~1000

|

100~1000

|

100~800

|

100~600

|

|

Cutting feed speed

|

mm/min

|

0.1~1000

|

0.1~1000

|

0.1~1000

|

0.1~1000

|

0.1~1000

|

|

Vertical moving distance of tool holder

|

mm

|

550

|

600

|

700

|

800

|

700

|

|

Tool rest horizontal moving distance

|

mm

|

400

|

450

|

700

|

550

|

700

|

|

Longitudinal fast moving speed

|

mm/min

|

16000

|

16000

|

16000

|

16000

|

16000

|

|

Transverse fast moving speed

|

mm/min

|

16000

|

16000

|

16000

|

16000

|

16000

|

|

Tool holder form

|

|

horizontal

|

horizontal

|

horizontal

|

horizontal

|

horizontal

|

|

Diameter of hydraulic chuck

|

mm

|

400/500

|

400/500

|

400/500/630

|

400/500/630

|

400/500/630

|

|

Main motor power

|

Kw

|

15

|

18.5

|

22

|

22

|

22

|

|

positioning accuracy

|

mm

|

±0.008

|

±0.008

|

±0.008

|

±0.008

|

±0.008

|

|

Re -positioning accuracy

|

mm

|

±0.004

|

±0.004

|

±0.004

|

±0.004

|

±0.004

|

|

Machine size

|

mm

|

2000x1900x3030

|

2000x1900x3030

|

2050x1800x3200

|

2050x1800x3200

|

2050x1900x3200

|

PRODUCT CONFIGURATION

Application

SALES AND SERVICE NETWORK

Hot Searches