- Product Details

- {{item.text}}

Quick Details

-

Power:

-

2.2-7.5kw

-

Quality:

-

High Reputation

-

mineral:

-

gold cip plant

-

Voltage:

-

380V or as customized

-

Keywords:

-

cip

-

keyword:

-

cil

-

Advantage:

-

high recovery

-

Installation:

-

Provide trommel screen setup video&work video

-

Certificate:

-

CE&SGS&ISO

Quick Details

-

Weight (KG):

-

500

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JXSC

-

Power:

-

2.2-7.5kw

-

Quality:

-

High Reputation

-

mineral:

-

gold cip plant

-

Voltage:

-

380V or as customized

-

Keywords:

-

cip

-

keyword:

-

cil

-

Advantage:

-

high recovery

-

Installation:

-

Provide trommel screen setup video&work video

-

Certificate:

-

CE&SGS&ISO

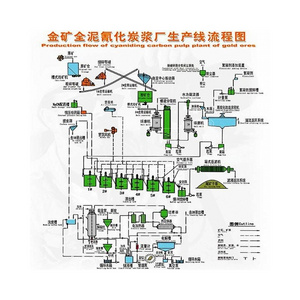

Product Description

Metal recovery or concentration by adsorption on activated carbon has been the dominant process for gold extraction after leaching by cyanide in aerated alkaline slurry. The continuous processes of gold recovery by adsorption on activated carbon in agitated tanks, namely the carbon-in-pulp (CIP) and the carbon-in-leach (CIL)processes, have been widely used since the 1970s.

In the CIL (Carbon in Leach) or CIP (Carbon in Pulp) plants while the precious metals are being dissolved by the cyanide solution in the large volume tanks the dissolved metals are adsorbed by the active carbon. These processes are generally preferred for therelatively high grade and lower reserve ore types with very fine graded precious metals.

Specifications&Parameters

|

Model.

|

Tank Spec:mm

(Diameter.* Height)

|

Effective Volume M

3

|

Impeller Diameter:mm

|

Power: kw

|

|

LT2.0×2.5

|

2000×2500

|

6

|

909

|

2.2

|

|

LT3.0×3.5

|

3000×3500

|

21

|

1130

|

4

|

|

LT3.5×3.5

|

3500×3500

|

30

|

1310

|

5.5

|

|

LT4.0×4.5

|

4000×4500

|

48

|

1750

|

7.5

|

|

LT4.5×5.0

|

4500×5000

|

71.5

|

1750

|

7.5

|

|

LT5.0×5.6

|

5000×5600

|

98

|

2046

|

11

|

|

LT6.5×7.0

|

6500×7000

|

195

|

2400

|

22

|

|

LT7.0×7.5

|

7000×7500

|

245.4

|

2400

|

22

|

|

LT8.0×8.5

|

8000×8500

|

342

|

3300

|

30

|

|

LT9.0×9.5

|

9000×9500

|

515

|

3900

|

37

|

|

LT10×10.5

|

10000×10500

|

705

|

4000

|

45

|

Application on site

JXSC Gold CIP Processing Plant in Kenya

JXSC has designed complete set Flowchart and provide complete set processing plant machines &all accessories for Kenya customer 12TPH (300TPD) Gold CIP Plant.

Also Have Provided After-sale Engineer Service, send engineers to Mine site for installation&commissioning guidance.

The Main Machines & Accessories include below:

1. Feeding + Crushing system crush rock from 210mm to below 5mm :

Feeding Hopper+Chute Feeder+ Rough Jaw crusher+belt conveyor+Fine jaw crusher+vibration screen+ Roller Crusher

2. Grinding System (grinding material to small powder 200mesh) :

Storage Bin+ Electromagnetic vibration feeder+ belt conveyor+Ball mill+HydroCyclone

3. Leaching Pretreatment :

include Thickener + Agitation tank ( for adjust density of slurry after thickener) +Liner vibrating screen

4. Leaching and Activated Carbon Adsorption processing :

include 2pcs double impeller Leaching agitation tank+ 7pcs double impeller Adsorption agitation tanks+ Roots blower(work for adsorption agitation tank)+ Liner vibrating screen for tailing dewatering+ Liner vibrating screen for screening carbon+ Cabon extractor +Cabon screen

5. Gold-loaded carbon desorption and electrolytic Stage:

Include : normal temperature& normal pressure Elution & Electrolysis system+Drying Oven for gold mud+ Gold smelting furnace

6. Carbon kiln for carbon regeneration

7. Tailing Water recycle system :

High pressure slurry pump+plate filter press+cone slurry tank for making suitable density of slurry before sending to filter

8. FIVE Reagent adding devices system:

each system include reagent agitation tank+reagent slurry pump+ reagent tank.

1) Flocculant make-up system for thickener

2) sodium cyanide reagent make-up system for 2pcs leaching agitation tank

3) Lime make-up system for 2pcs leaching agitation tank (for PH control)

4) sodium hydroxide&hydrochloric acid reagent make-up system for cone agitation tank

5) sodium hydroxide&&clean water&sodium cyanide reagent make-up system for Elution & Electrolysis system

9. Water pumps for water supply to complete plant .

1. Slurry Pumps for plant

2. Compelete set electric control pannels

3. Complete set Cables&wires

4. Diesel Generator for plant machines power

6. Complete set Water pipes &slurry pipes

Company&Factory

JIANGXI SHICHENG MINE MACHINERY FACTORY

It is a leading mining machinery manufacturer with over 30 years experiences in this industry, providing complete set processing equipment for Gold ore,Tin ore, Tungsten ore, Iron ore, Diamond, Coltan ore, Silica sand, Zircon sand, Black sand, Chrome ore, etc. As well as complete set small lab mining machines are available.

Core Advantages as below :

1.+30 years history FACTORY at mining machinery

2.Provide engineer team after sales service

3.Provide Complete set mineral processing equipment

4.Provide Sample testing service in factory lab for free

5.Provide professional Mining Solution Consulting

6.Provide professional flowchart designing and drawing

7.Provide engineer door to door service for installation,commissioning,starting up and training.

1.+30 years history FACTORY at mining machinery

2.Provide engineer team after sales service

3.Provide Complete set mineral processing equipment

4.Provide Sample testing service in factory lab for free

5.Provide professional Mining Solution Consulting

6.Provide professional flowchart designing and drawing

7.Provide engineer door to door service for installation,commissioning,starting up and training.

FAQ

1.How is the quality of your products?(mining equipment/machine)

Answer: Our products are manufactured strictly according to national and international standard, and we will do a test on every machine before delivery.

2.Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description or promise we made before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before factory delivery, which is international trade practice; Finished product pictures will be provided to customers before delivery.

Answer: Our products are manufactured strictly according to national and international standard, and we will do a test on every machine before delivery.

2.Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description or promise we made before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before factory delivery, which is international trade practice; Finished product pictures will be provided to customers before delivery.

Hot Searches