- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HUAN

-

Weight:

-

600kg

-

Dimension(L*W*H):

-

2650*1050*1800mm

-

Product:

-

cap liner insertion machine

-

Keywords:

-

plastic cap liner lining machine

-

Name:

-

plastic cap wadding machine

-

Usage:

-

Capping slitting

-

Certification:

-

CE

Quick Details

-

Voltage:

-

220V/380V/Customized

-

Power:

-

1kw

-

Place of Origin:

-

China

-

Brand Name:

-

HUAN

-

Weight:

-

600kg

-

Dimension(L*W*H):

-

2650*1050*1800mm

-

Product:

-

cap liner insertion machine

-

Keywords:

-

plastic cap liner lining machine

-

Name:

-

plastic cap wadding machine

-

Usage:

-

Capping slitting

-

Certification:

-

CE

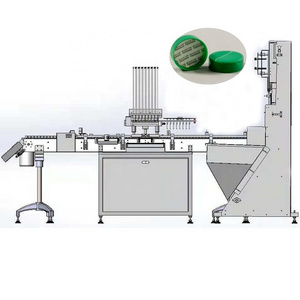

Cap lining machine cap wadding machine cap liner inserting putting machine

Cap liner machine characteristics:

Original Japan PLC control, man-machine interfere,intelligent recognition of defective products are automatically rejected. Production figures can be set. When automatic alarm is on it can shut down.

a. This machine replaces the handwork. It automatically inserts the liner into the bottle cap, and can raise work efficiency greatly.

b.Reasonable Liner Sealing, Fast speed, High efficiency, Safe and Sanitary product.

c. Suitable for situation which requests the hygiene condition strictly, avoiding second pollution to the material, economizing a disinfectant craft;

d. Sorting Cap System attaches the function of cap elimination, in order to make sure every finished bottle cap upward.

e. Transfer and transport the cap and accurate targeting system;

f. The whole machine adopts PLC to control. If there’s no chip, no cap, it will alarm;

|

1 |

Main electronic parts |

SIEMENS |

|

2 |

Electric protection switch |

SIEMENS |

|

3 |

Circuit breaker |

SIEMENS |

|

4 |

PLC |

MITSUBISH |

|

5 |

Touch screen |

WEINVEW |

|

6 |

Transducer |

MITSUBISH |

|

7 |

Photoelectricity switch |

AUTONICS |

|

8 |

Pneumatic element |

AIRTAC |

|

9 |

Pressure sensor |

SMC |

|

10 |

Motor |

SIEMENS OR ZHONGDA |

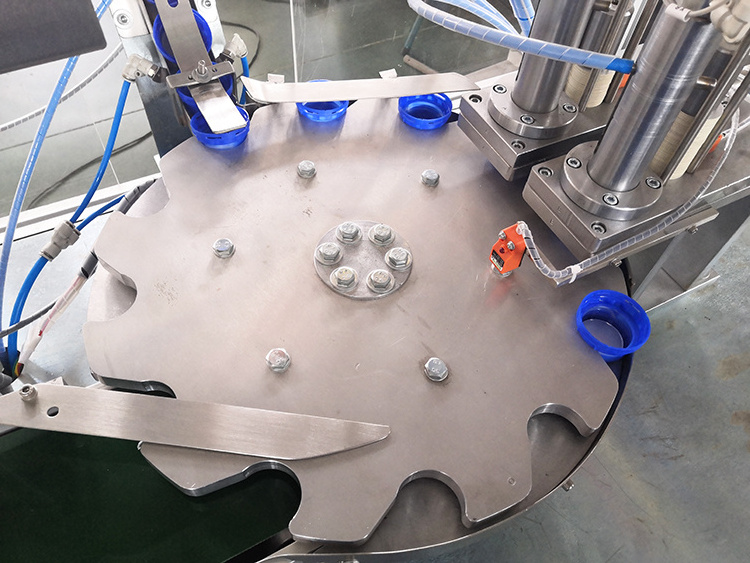

Detail of cap liner machine

|

|

Application of cap liner machine

Usage of cap liner machine

Our factory a manufacturer of plastic mechanical auxiliaries with well-equipped testing facilities and strong technical force. With a wide range, good quality, reasonable prices and stylish designs,our main products are: empty bottle bagging packing machine, plastic cap liner wadding machines, automatic leak detection machines, semi-automatic leak detection machines, capping machines, electromagnetic sealing machines, plastic products conveyor belts.All machines have 24 hours for engineer response.It is our continuous progress and good service that have not only won us the praise of more than 20 countries and regions in the world, but also the recognition of many manufacturers in the industry. At present, our products have been used by global companies such as India CMP Plastic Machinery Co., Ltd. More than 400 blow molding machine manufacturers and mold manufacturers provide supporting services.We welcome our customs all over the world.

Service for cap liner machine

Cho os ing the sulitable machine:

According to the customer's requirement, we will recommend the suitable machine for you.

Warranty time:

O ur waranty ime is 12 months after the delivery. During this period, any qual i ty problem of the machine, please contact us freely , We will invite professional engineers for both online and offline guidance .

Shipping and Training:

We will provide machine i nstall video and run video to our customers before delivery. we should provide the training for the buyer's employee for free in buyer's factory.Or the buyer let his employee come our factory learn with our engineer.

Installation and test:

when the machine reaches the buyer's factory,the buyer could tell us, we will dispatch an engineer to the buyer's factory to help install and test the machine until it runs normally.

1.Machine body is covered by waterproof film firstly, and then fixed on exported wooden pallets with bolts and wires.

2.The electric controlling parts and spare parts are loaded separately in wooden box.

3.The auxiliary equipments are packaged in wooden box as well.

4.All wooden material is fumigation certificated and safe for exporting to all over the world.

1. Q: -Can the machine customized only for my products?

A: - Yes, our machines can be customized as per clients’ requirements, including the structure special design and brand of parts special request.

2. Q: -How about the machine mould?

A: - Customized machine mould can be supplied for you.Our Machine and mould can be tested for samples and smooth matching before shipping. Mould raw material is various for optional.

3. Q: -What is the business item for this project ?

A: - a. Delivery Date: within 45 working days after receive the deposit and samples or drawing confirmed .

b. Port of Loading: SHANGHAI, CHINA.

c. Payment: T/T/LC,alibaba trade assurance

4. Q: -What is the warranty period?

A: - Our machine main parts is one year warranty with a lifelong maintenance.