- Product Details

- {{item.text}}

Quick Details

-

Size:

-

Customer's Drawings

-

Thickness:

-

0.1-12.00mm

-

Standard:

-

DIN GB ISO JIS BA ANSI

-

Design file format:

-

DWG, DXF, step, x_t, top, IGS

-

Mold manufacturing cycle:

-

3 to 10 weeks, depending on the precision you need for your product.

-

Forming method:

-

Metal stamping/cutting/punching/bending/welding/deep drawing

-

Press tonnage:

-

100T to 400T

Quick Details

-

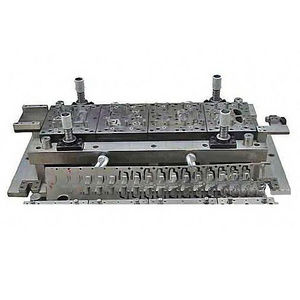

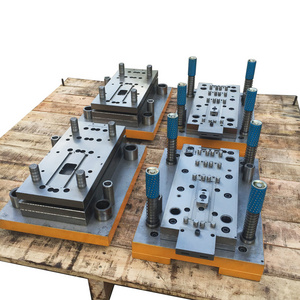

Shaping Mode:

-

Punching Mold

-

Place of Origin:

-

China

-

Material:

-

SKD11, DC53, D2, 45#, CR12MOV, P20, etc

-

Size:

-

Customer's Drawings

-

Thickness:

-

0.1-12.00mm

-

Standard:

-

DIN GB ISO JIS BA ANSI

-

Design file format:

-

DWG, DXF, step, x_t, top, IGS

-

Mold manufacturing cycle:

-

3 to 10 weeks, depending on the precision you need for your product.

-

Forming method:

-

Metal stamping/cutting/punching/bending/welding/deep drawing

-

Press tonnage:

-

100T to 400T

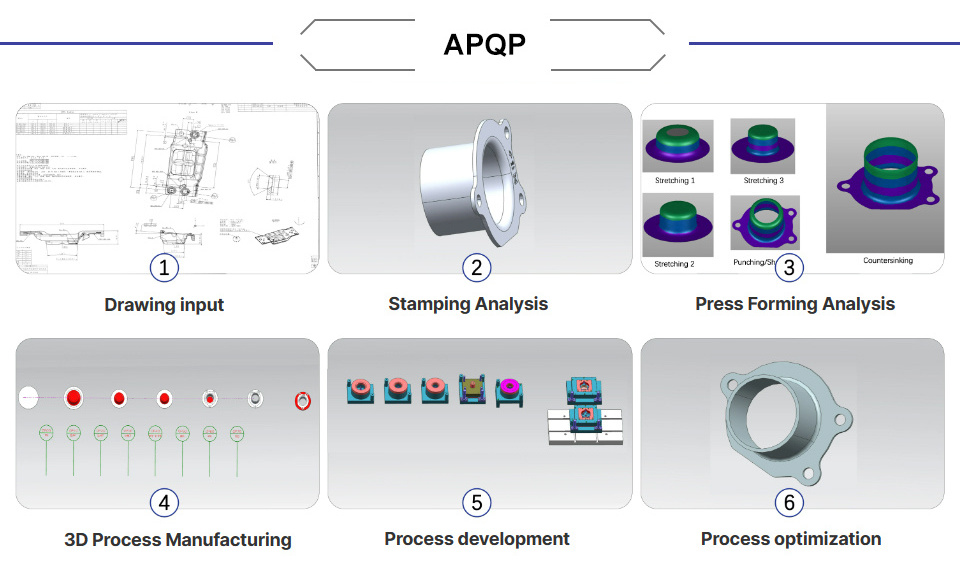

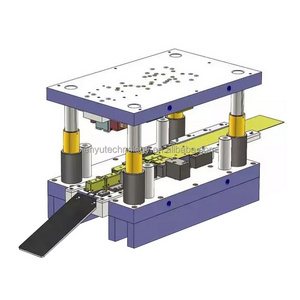

Product Description

|

Product name

|

IATF16949 factory custom precision metal progressive stamping die factory

|

|

|

|

||||

|

Materials

|

DC53, D2, 45#, CR12MOV, P20, etc

|

|

|

|

||||

|

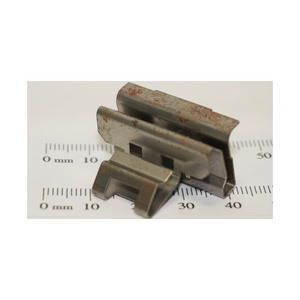

Product thickness

|

0.1-12.00 mm

|

|

|

|

||||

|

Finish

|

Nickel plating, tin plating, tin plating, zinc plating, chromium plating, heat treatment, electroplating, degreasing, electrophoresis, etc.

|

|

|

|

||||

|

Standard

|

DIN GB ISO JIS BA ANSI

|

|

|

|

||||

|

Design file format

|

DWG, DXF, step, x_t, top, IGS

|

|

|

|

||||

|

Size

|

On request.

|

|

|

|

||||

|

Mold manufacturing cycle

|

3 to 10 weeks, the exact time may depend on the precision you need for the product.

|

|

|

|

||||

|

Forming method

|

Metal stamping/cutting/punching/bending/welding/deep drawing

|

|

|

|

||||

|

Press tonnage

|

100T to 400T

|

|

|

|

||||

|

EXP

|

15 years of experience in automotive mold design and manufacturing and automotive metal parts manufacturing

|

|

|

|

||||

|

Apply

|

Industry, furniture, automobiles, motorcycles, household appliances, computers, etc

|

|

|

|

||||

|

Cycle count

|

Under normal use, the life of the mold can reach 300,000 cycles.

|

|

|

|

||||

|

|

|

|

|

|||||

FAQ

Q1: Is your organization committed to the concept oftotal quality management?

A: Yes, no matter whether in laser cutting,bending,stamping or CNC machining,QC will conduct the first sample inspection and random inspection during the processing

to ensure the quality of the products.

Q2: How many checks are performed on a project?

A: Usually, products will go through the following four inspections: incoming inspection, production first inspection, sampling inspection, and shipment inspection. Among them,sampling inspection will be conducted multiple times.

Q3: Will you be able to work with our engineering team to review drawings and provide quick, stimated pricing for desired changes?

A: Yes, our engineers respond very quickly. If there is anything to be modified in the product, we can offer you a new price as soon as you tell us.

Q4: What kinds of information do you need for a quote?

A: Kindly please provide the product drawing in PDF, and will be better if you can provide it in .dwg / .stp /. igs / .stl, Send drawing.

Q5: What tolerances can Bergek achieve?

A:There is not a given set of tolerances that fits all processes and materials. In every case, the final tolerances on your part will depend on a number of factors, including but not limited to:●Part size ●Design Geometry ●The number, type, and size of features●Material(s) ●Surface finish ●Manufacturing process Once your order is confirmed, we will review your design and provide a design for an facturing review, pointing out any areas where we may not be able to achieve your desired tolerances. It’s helpful if you can specify which areas in your design have critical tolerances that must be met and which can be slightly modified if needed to reduce the time and costs involved. Here are some general tolerance guidelines: General tolerances for CNC machining in metal and plastic Refer to DIN ISO 2768 All manufacturing and technical specifications need to be clearly specified in the 2D drawings in order to be followed.

Q6: Will your company signan NDA?

A: Yes, We will strictly follow the confidentiality agreement to protect the rights and interests of our customers.

Q7: OEM/ODM customer's logo printed is available?

A:Yes,OEM/ODM,customer's logo welcomed.

Q8: if we don't have a shipping forwarder in China,would you do this for us?

A: We can offer you the best shipping line to ensure you can get the goods timely at the best price.

to ensure the quality of the products.

Q2: How many checks are performed on a project?

A: Usually, products will go through the following four inspections: incoming inspection, production first inspection, sampling inspection, and shipment inspection. Among them,sampling inspection will be conducted multiple times.

Q3: Will you be able to work with our engineering team to review drawings and provide quick, stimated pricing for desired changes?

A: Yes, our engineers respond very quickly. If there is anything to be modified in the product, we can offer you a new price as soon as you tell us.

Q4: What kinds of information do you need for a quote?

A: Kindly please provide the product drawing in PDF, and will be better if you can provide it in .dwg / .stp /. igs / .stl, Send drawing.

Q5: What tolerances can Bergek achieve?

A:There is not a given set of tolerances that fits all processes and materials. In every case, the final tolerances on your part will depend on a number of factors, including but not limited to:●Part size ●Design Geometry ●The number, type, and size of features●Material(s) ●Surface finish ●Manufacturing process Once your order is confirmed, we will review your design and provide a design for an facturing review, pointing out any areas where we may not be able to achieve your desired tolerances. It’s helpful if you can specify which areas in your design have critical tolerances that must be met and which can be slightly modified if needed to reduce the time and costs involved. Here are some general tolerance guidelines: General tolerances for CNC machining in metal and plastic Refer to DIN ISO 2768 All manufacturing and technical specifications need to be clearly specified in the 2D drawings in order to be followed.

Q6: Will your company signan NDA?

A: Yes, We will strictly follow the confidentiality agreement to protect the rights and interests of our customers.

Q7: OEM/ODM customer's logo printed is available?

A:Yes,OEM/ODM,customer's logo welcomed.

Q8: if we don't have a shipping forwarder in China,would you do this for us?

A: We can offer you the best shipping line to ensure you can get the goods timely at the best price.

Hot Searches