2.Storage tank with level sensor to detect the syrup level

3.The dissolving tank bottom equipped with pneumatic valve and tube filter to prevent the syrup stuck the lobe pump

4. The pipes are equipped with filter device

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Power:

-

16kw

-

Dimension(L*W*H):

-

customized

-

Weight:

-

3000 KG

-

Application fields:

-

Candy making industry

-

Machinery Capacity:

-

150kg/h

-

Machinery Function:

-

Candy making

-

Marketing Type:

-

New Product 2023

-

Application:

-

CANDY

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Production capacity:

-

300-450kg/h

-

Product name:

-

jelly candy

-

Model:

-

GDQ

-

Function:

-

Multifunctional

-

Raw material:

-

316

Quick Details

-

Model Number:

-

GD150Q

-

Brand Name:

-

TGMACHINE

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

380v

-

Power:

-

16kw

-

Dimension(L*W*H):

-

customized

-

Weight:

-

3000 KG

-

Application fields:

-

Candy making industry

-

Machinery Capacity:

-

150kg/h

-

Machinery Function:

-

Candy making

-

Marketing Type:

-

New Product 2023

-

Application:

-

CANDY

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Production capacity:

-

300-450kg/h

-

Product name:

-

jelly candy

-

Model:

-

GDQ

-

Function:

-

Multifunctional

-

Raw material:

-

316

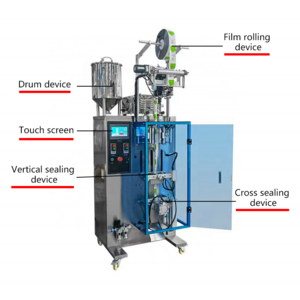

Product Description

The gummy candy line was specially innovated by our R&D department according to the market, which can produce gummywith multiple shapes and variety colors on base of advanced technology process. It is an ideal machine to produce superiorquality gummy candy of single color and double color; By change-over molds or depositors, different color and different shape of gummy can be also produced. The on-line mixer achieves the quantitative dosing and mixing of the flavor, color and acid. High degree of automation can produce super quality of gummy, at the same time it saves the manpower and the space occupation.

|

Model

|

GD150Q

|

GD300Q

|

GD450Q

|

GD600Q

|

|||

|

Capacity

|

150kg/h

|

300kg/h

|

450kg/h

|

600kg/h

|

|||

|

Candy Weight

|

According to the size of candy

|

|

|

|

|||

|

Working Condition

|

20~25° temperature humidity 55%

|

|

|

|

|||

|

Electric Power Needed

|

16kw/380v

|

26kw/380v

|

32kw/380v

|

36kw/380v

|

|||

|

Total Length

|

18m

|

20m

|

20m

|

22m

|

|||

|

Weight Of Machine

|

3000kg

|

4500kg

|

5000kg

|

6000kg

|

|||

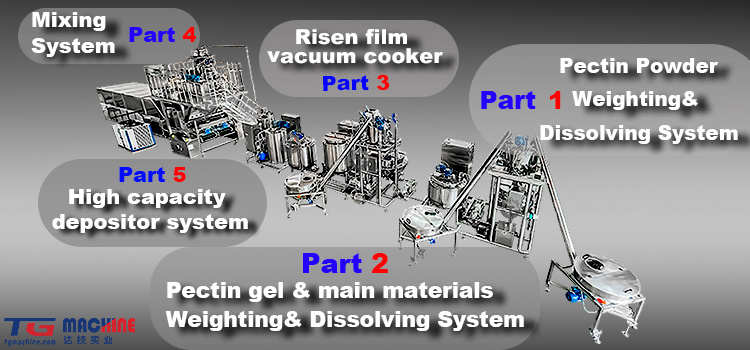

Product Detail

Part 1:Pectin powder weighing and dissolving system

1.Automatic control for the dissolving temperature, with PLC and touch screen individual control for high automation

Part 2:Pectin gel and main materials weighing and

dissolving system

Part 3:Risen film vacuum cooker

1. PEEK polymer material, wear-resistant and high temperature resistant

2. Plunger type dosing pump to ensure all the syrup heated evenly for better quality

3. Scraping cooking to avoid any over-burn situation

4. Vacuum cooker to take out the bubble, which can make the cooking in a lower temperature and concentrate moisture

5. The dissolving tank equipped with scraper to ensure the syrup can be heated up from bottom to the top with faster speed, no over-burn situation, more stable syrup quality

Part 4:Bath type CFA mixing system

Bacth type CFA and other

activities dosing mixing system

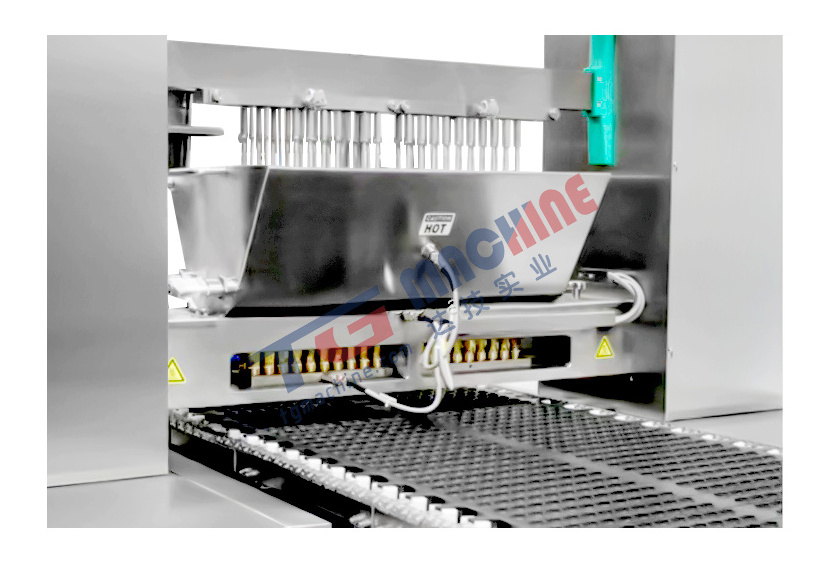

Part 5:

Advanced high capacity gummy depositor

1 .Instead of install the driving system on the frame, the new type depositor driving system installed on the depositor, this ensure more accurate depositing and less wearing, while the manufacturing cost is much higher

2. The oil spray device with each nozzle individual control, each time spray 80 nozzles for double mold.

Other Parts

Oil sprayer

Cooling system

PLC Control

TG Machine Department of candy

mold

manutacturing is specialized in design, aluminum alloy molds, silicone molds and food-grade PC molds.development, manutacturing and global sales of aluminum alloy molds,silicone molds and tood-grade PC molds. They always gives top priority tocustomers' demands. Our experts provide you with technical support,technical advisory, solutions, timely communication and short delivery time at any time.

Display of some accessories

Finished Products

Company Introduction

Shanghai Target Industry Co., Ltd.

TGMachine is proud of the machine design with sanitary and easy washing structure for Gummy candy with Vitamin and Minerals. Etc functional products. It is ideal equipment that can produce good quality gummies with the saving of both the manpower and the space occupied. Optional with Touch screen, SERVO and PLC for Automatic operation, one shot system can make one color, two color or multi-color, center filled Gummy candy (optional) also available just change the manifold and nozzles. The cooling tunnel includes automatic Chain type/Air Knife/Brush de molding system as option. The complete line was designed according to pharmaceutical machine standard, higher level sanitary structure design and fabrication, all stainless steel materials are SUS304 and SUS316L in the line and it can be equipped with UL certified or CE certified components for CE or UL certificated.

Packing & Delivery

1.We provide shipping methods:Courier service,Air transport,Sea Transport

2.

Delivery term :EXW,FOB,CIF,CNF, Door to Door etc.

FAQ

Q:

What is your after-sales

service

?

A: 1)

Expatriate Maintenance.

2)

Online Vedio Technical Support .

3)

Free Spare Parts.

4)

Perfect Quality Program,100% Test Before Delivery.

Q:Are you trading company or manufacturer ?

A:

We integrate industry and trade

, which is our advantage. We can give you lower priceand more comprehensive service

Q:Do you provide any recipes for the product?

A: Yes ,we will provide a basic recipe. and clients can add different color and flavor on that base.

Q:What are the advantages of your product over others?

A:We are more concerned about food safety than them, so our machine can be washed with water all over the body, and the pouring part has no sanitary defects; We can adjust the configuration of the machine according to your budget /output and give you a satisfactory answer.

Q:Do you provide any recipes for the product?

A: Yes ,we will provide a basic recipe. and clients can add different color and flavor on that base.

Q:What are the advantages of your product over others?

A:We are more concerned about food safety than them, so our machine can be washed with water all over the body, and the pouring part has no sanitary defects; We can adjust the configuration of the machine according to your budget /output and give you a satisfactory answer.

Hot Searches