Mini Geared Motor selection process

Need help determining the motor suitable for your application? Check our motor selection guide or visit the ISL motor database.In the conceptual design stage, the motor selection process may be challenging, but our engineers will help. We provide concierge services for all DC motor and gear motor projects. Our team of engineers works with you to provide the best component solutions.The following points can help you determine and select the most suitable motor or gear motor for our application.

▎Design requirements – the design evaluation stage of studying product development requirements, design parameters, equipment functions, and product optimization.

▎Design calculations – calculations used to determine which motor is best suited for your application. The design calculation determines the transmission ratio, torque, rotating mass, service factor, suspension load, and test analysis.

▎Type of DC motor/gear motor - the most common motor converts electrical energy into mechanical energy. These types of motors are powered by direct current (DC).

▎Motor Specifications – Once the design calculations are performed, and the application parameters are defined, you can use this data to determine which motor or gear motor will best fit your application. Some of the most common specs to consider when selecting a motor or gear motor would be:

* * Voltage

* Current

* Power

* Torque

* RPM

* Life Expectancy / Duty Cycle

* Rotation (CW or CCW)

* Shaft Diameter and Length

* Enclosure Restrictions

▎Design calculations – calculations used to determine which motor is best suited for your application. The design calculation determines the transmission ratio, torque, rotating mass, service factor, suspension load, and test analysis.

▎Type of DC motor/gear motor - the most common motor converts electrical energy into mechanical energy. These types of motors are powered by direct current (DC).

▎Motor Specifications – Once the design calculations are performed, and the application parameters are defined, you can use this data to determine which motor or gear motor will best fit your application. Some of the most common specs to consider when selecting a motor or gear motor would be:

* * Voltage

* Current

* Power

* Torque

* RPM

* Life Expectancy / Duty Cycle

* Rotation (CW or CCW)

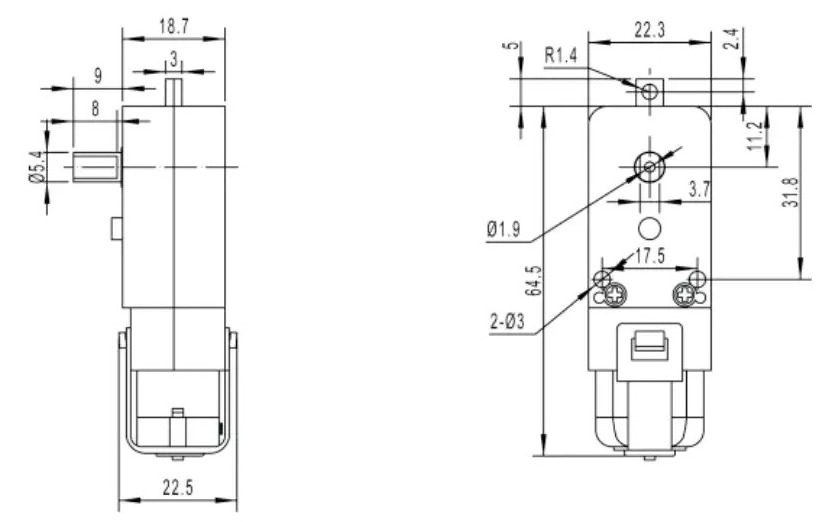

* Shaft Diameter and Length

* Enclosure Restrictions