- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Leizhan

-

Voltage:

-

380v / 450v

-

Power:

-

300kw

-

Dimension(L*W*H):

-

According to types

-

Weight:

-

1200 kg

-

Product Name:

-

kraft paper mill recycled paper making machine

-

Raw material:

-

waste paper, wood pulp

-

Finished Products:

-

Kraft paper

-

Basis weight:

-

80-220gsm

-

Trimmed Width:

-

1880-5800mm

-

Operation speed:

-

100-800m/min

-

Application:

-

for paper manufacturing company

-

Technology:

-

advanced

-

Experience:

-

since 1980

-

Keyword:

-

paper making machine

Quick Details

-

Production Capacity:

-

30-500t/d

-

Product Type:

-

Kraft Paper mill machine

-

Processing Type:

-

Paper machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Leizhan

-

Voltage:

-

380v / 450v

-

Power:

-

300kw

-

Dimension(L*W*H):

-

According to types

-

Weight:

-

1200 kg

-

Product Name:

-

kraft paper mill recycled paper making machine

-

Raw material:

-

waste paper, wood pulp

-

Finished Products:

-

Kraft paper

-

Basis weight:

-

80-220gsm

-

Trimmed Width:

-

1880-5800mm

-

Operation speed:

-

100-800m/min

-

Application:

-

for paper manufacturing company

-

Technology:

-

advanced

-

Experience:

-

since 1980

-

Keyword:

-

paper making machine

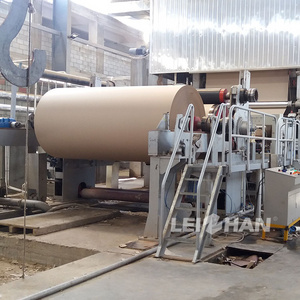

Kraft Paper mill production machines and equipment, recycled paper making machine

Application

This paper making machine mainly use waste carboard as raw material, then for kraft paper making. W e can offer the whole line of paper making.

Main specification

1.Trimmed width: 1880-5800mm

2.Raw material: recycled paper, waste cardboard

3.Production capacity: 20-500t/d

4.Finished products: kraft paper

5.Basis weight: 60-220g/m2

6.Operation speed: 100-800m/min

| Paper grade | high strength kraft paper |

| Trim width(mm) | 1880-5800 |

| Basis weight(g/m2) | 60-220 |

| Operating speed(m/min) | 100-800 |

| Capacity(t/d) | 20-500 |

Raw material

Process Flow Diagram

Raw materials (waste paper)——chain conveyor——pulper——hign density cleaner——pressure screen——fiber separator——reject separator ——low density cleaner——inflow pressure screen——paper making machine——the big finished jumbo roll paper

Main structure of paper machine :

1.Wire section: Dewater initially and form even wet paper.

2.Press part: The dryness after press section is about 25-42%

3.Drying part: The dryness after drying section is 92-95%. This section consists of several groups dryer cylinders. There is a gas hood to prevent steam evaporating.

4. Winding part: Cylinder type winding machine 1 set, Rewinding machine 1 set.

5. Driving & control part: AC frequency conversion speed, section drive.

Paper products :

Project: Whole set of 150t/d Kraft Liner, Fluting, White board paper, T-paper Stock Preparation Line.

Project: 600T/D T-Paper, Fluting&Testliner Paper production line .

Project: 30 tpd Toilet Tissue Roll Making Project.