- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

Quick Details

-

Injection Rate (g/s):

-

186 g/s

-

Injection Weight (g):

-

119 g

-

Weight (KG):

-

3450 kg

-

Place of Origin:

-

Zhejiang, China

Shenzhen Deligao Mould Plastic Co.,Ltd

DELIGAO INDUSTRIAL(HK)CO.,LTD

Engaged in used injection molding machine for 19 years. Have a lot of experience.

Technically, our company can provide customers with: Recondition and Repaint. Overseas assembly. Transform variable pump, servo. Wait one stop service.

Our company has huge warehouse and source of goods.

The existing injection molding machine in the warehouse:

Provide various kinds from

30

T-4000T,

Place of origin:Japan,Korean,Taiwan,HK,China mainland.

Overall functions and stable capacity and high quality

Low cost, high efficiency and big ROI!

The stock keep more than 300 set of machines, provide different series and size of brands.Such as Engel,JSW,NESSEI,NIIGATA,TOSHIBA,TOYO,FCS,ChenHsong,HAITIAN...

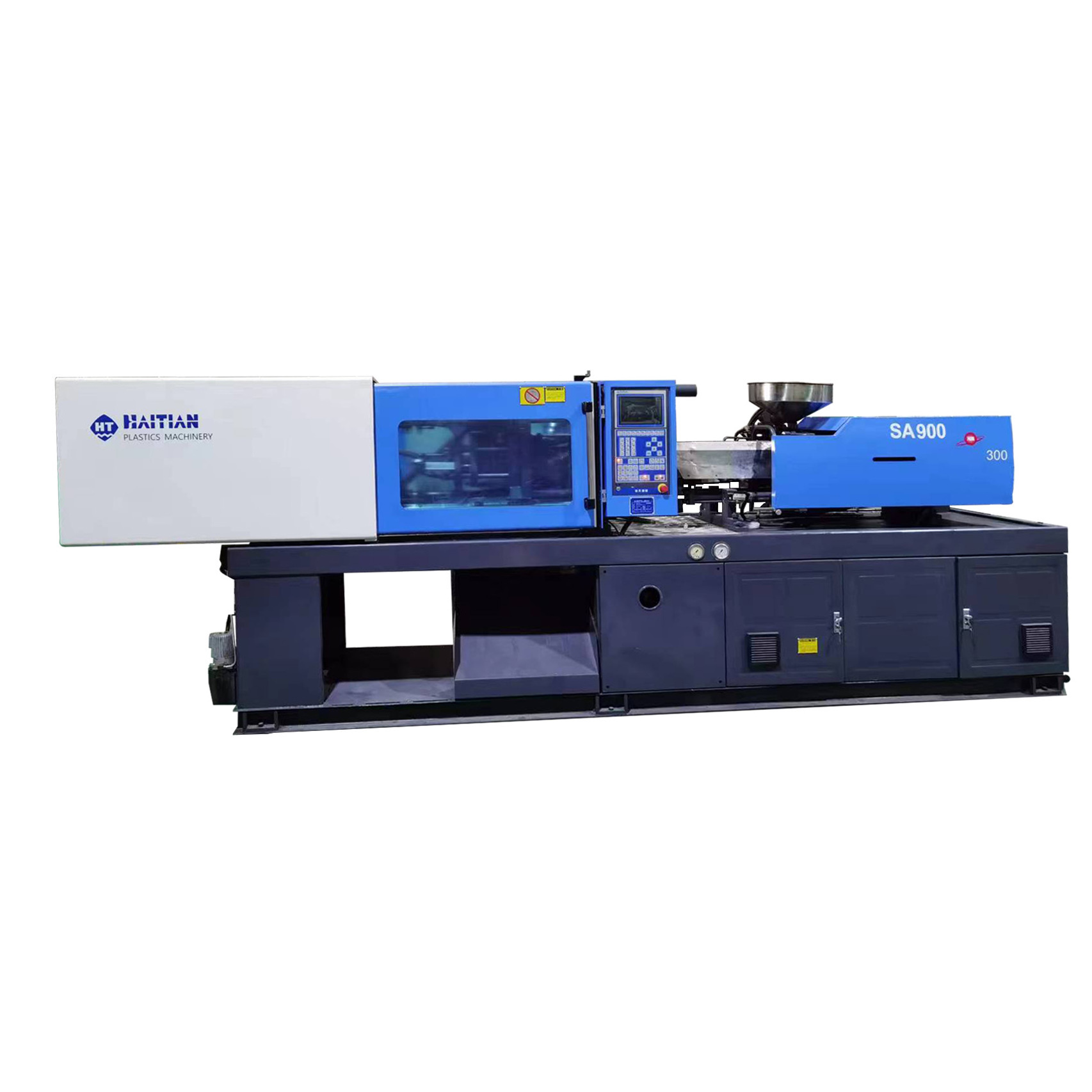

SA900

|

INJECTION UNIT |

|

A |

B |

C |

|

Screw Diameter |

mm |

34 |

36 |

40 |

|

Screw L/D Ratio |

L/D |

21.2 |

20 |

18 |

|

Shot Size(Theoretical) |

cm 3 |

131 |

147 |

181 |

|

Injection Weight(PS) |

g |

119 |

134 |

165 |

|

Injection Pressure |

Mpa |

206 |

183 |

149 |

|

Screw Speed |

rpm |

0 ~205 |

||

|

CLAMPING UNIT |

|

|

||

|

Clamp Tonnage |

KN |

900 |

||

|

Toggle Stroke |

mm |

310 |

||

|

Space Between Tie Bars |

mm |

360x360 |

||

|

Max.Mold Height |

mm |

360 |

||

|

Min.Mold Height |

mm |

150 |

||

|

Ejector Stroke |

mm |

100 |

||

|

Ejector Tonnage |

KN |

33 |

||

|

Ejector Number |

Piece |

5 |

||

|

OTHERS |

|

|

||

|

Max.Pump Pressure |

MPa |

17.5 |

||

|

Pump Motor Power |

kw |

7.5 |

||

|

Heater Power |

kw |

6.2 |

||

|

Machine Dimension(LxWxH) |

m |

4.5x1.25x1.9 |

||

|

Machine Weight |

t |

3.45 |

||

|

Hopper Capacity |

kg |

25 |

||

|

Oil Tank Capacity |

L |

230 |

||

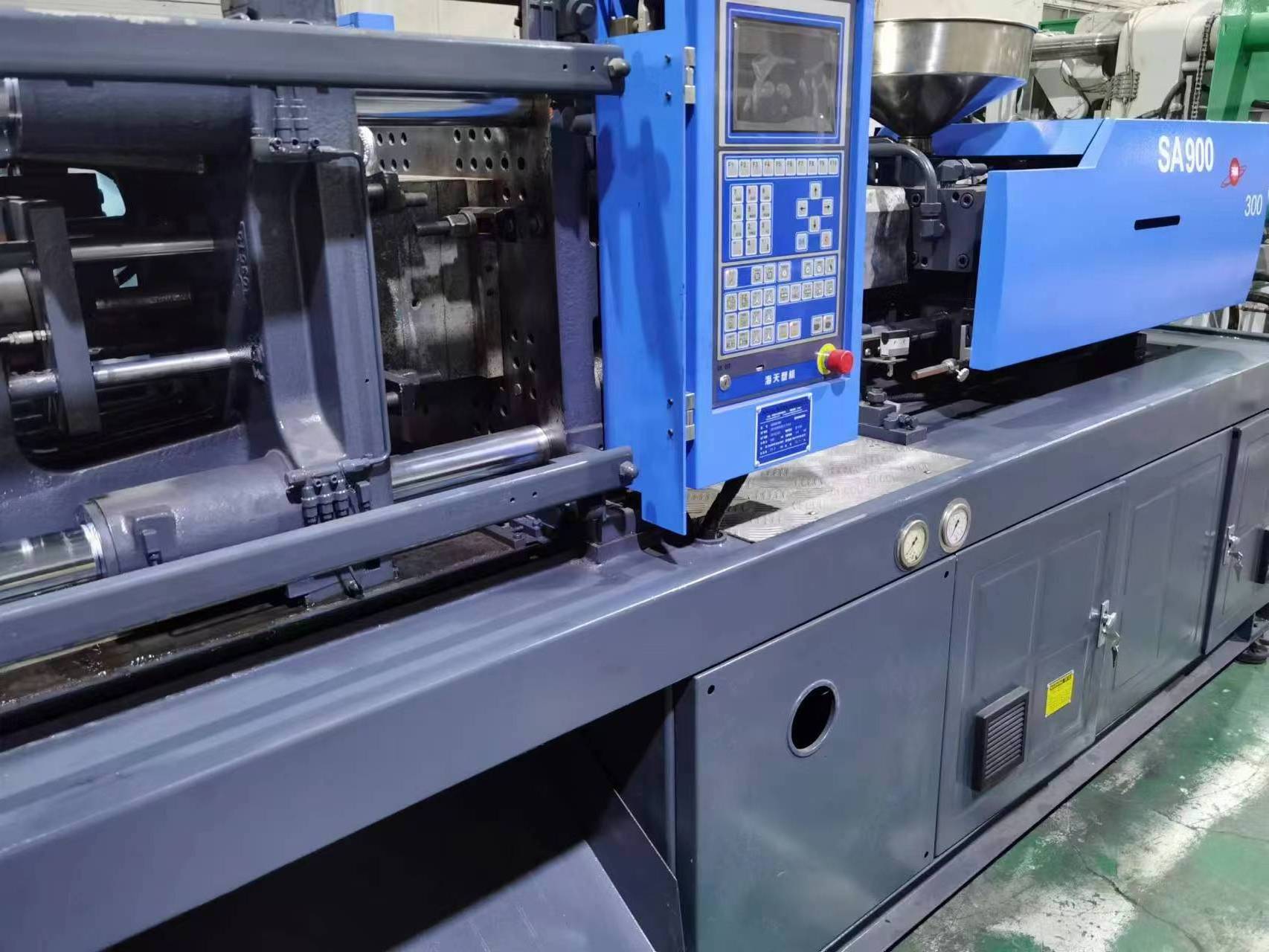

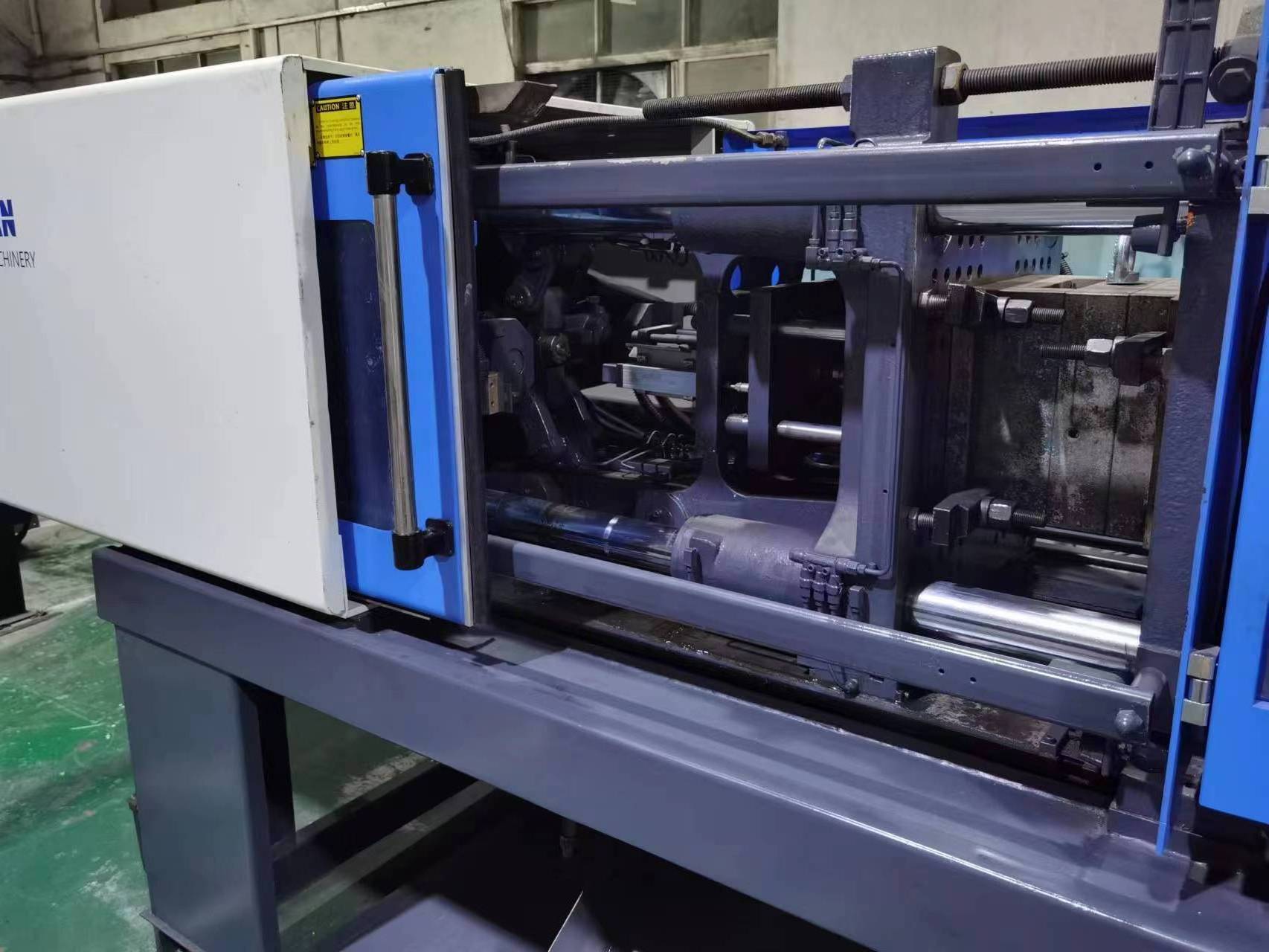

High hardness : the template stress distribution is uniform, the deformation is small, and the precision of the product is effectively improved; the pressure center template structure is adopted to effectively improve the precision of the product.

Longer life

: The new graphite steel casing greatly enhances the lubrication of the crankshaft and tie rods, smooth running of the mold clamping, longer service life and less maintenance.More precise: integral guide rod support, double-cylinder balanced injection device, so that the screw is evenly balanced during the advancement of the injection, linear advancement.

More efficient

: highly optimized clamping unit, smoother high-speed opening and closing mold, effectively shortening cycle time,Innovative drive system, patented servo motor gear pump design.