- Product Details

- {{item.text}}

Quick Details

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

2000

-

Rolling mill type:

-

high-speed TMT threaded steel rolling mill production line

-

Color:

-

Customized

-

Advantages:

-

Large output and high efficiency

-

Raw material:

-

steel billet

-

Steel grade:

-

High/low alloy steel, structural steel, carbon steel

-

After sales service provided:

-

Engineers can repair machinery overseas

-

Packaging:

-

Wooden box and nude

-

Delivery details:

-

3 months

-

Rolling speed:

-

12-18 meters/second

-

Input materials:

-

150x150x12000mm steel billet

Quick Details

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

HANI

-

Voltage:

-

380-440V

-

Power:

-

customized

-

Dimension(L*W*H):

-

customized

-

Weight (KG):

-

2000

-

Rolling mill type:

-

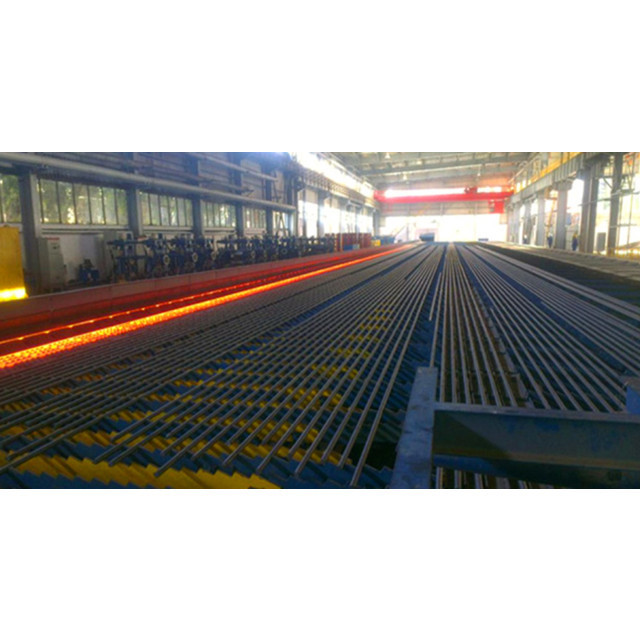

high-speed TMT threaded steel rolling mill production line

-

Color:

-

Customized

-

Advantages:

-

Large output and high efficiency

-

Raw material:

-

steel billet

-

Steel grade:

-

High/low alloy steel, structural steel, carbon steel

-

After sales service provided:

-

Engineers can repair machinery overseas

-

Packaging:

-

Wooden box and nude

-

Delivery details:

-

3 months

-

Rolling speed:

-

12-18 meters/second

-

Input materials:

-

150x150x12000mm steel billet

Products Description

Parameters

|

Type

|

Rolling Mill Specification

|

Max./Min Roll Diameter

Φmm

|

Roll Body Length

mm

|

Max. Rolling Force

(t)

|

Largest Rolling Torque

t.m

|

|

Short Stress Path Rolling Mill

|

Φ600 Hi 2

|

650/570

|

800

|

244

|

28

|

|

|

Φ550 Hi 2

|

600/500

|

800

|

220

|

18

|

|

|

Φ450 Hi 2

|

495/420

|

700

|

140

|

12.2

|

|

|

Φ400 Hi 2

|

430/370

|

650

|

90

|

4.28

|

|

|

Φ350 Hi 2

|

380/330

|

600

|

71

|

2.4

|

|

|

Φ320 Hi 2

|

380/330

|

600

|

61

|

2.2

|

Technological Process

Reheating Furnace

The reheating furnace is a three-stage continuous pusher-type reheating furnace with an effective size of 8400mm *18096mm, a

single row of feed, coke oven gas as fuel, and a design capacity of 80t/h.

Roughing Mill

The roughing mill consists of six flat-vertical short stress mills arranged alternately. The nominal diameter of the roll is

550mm, and the length of the roll body is 760 mm. The range of application is 610 mm to 520 mm.

There is a crank flying shear at the exit of rough rolling mill. The maximum cross-section is 4000mm. It is used to cut the head

and tail of the rolled piece after rough rolling and to break the rolled piece in case of an accident.

Intermediate Rolling Mill

The intermediate rolling mill is composed of six short stress mills arranged alternately by horizontal and vertical mills without

archway. The nominal diameter of the roll is 400 mm, and the length of the roll body is 650 mm. The range of application is 430 mm

to 370 mm.

There is a crank flying shear at the exit of the medium rolling mill. The maximum section of the shear is 2050 mm. It is used for

cutting the head and tail of the rolled piece after medium rolling and breaking the rolled piece in case of an accident.

Finishing Mill

The finishing mill consists of three flat, one vertical and two flat-vertical convertible short stress mills without archway. The

nominal diameter of the roll is 350 mm, and the length of the roll body is 650 mm. The range of application is 370 mm to 310 mm.

The finishing mill is equipped with a crank rotary changeable flying shear with a maximum shear section of 1300 mm and a length of

45 m to 72.

Bar Rolling Mill Cooling Bed

The cold bed is a stepping rack type with an area of 8m*78m, a rack spacing of 300mm/600mm, a pitch of 80mm and a working period

of less than 2.8s.

Fixed Length Cold Shear

Fixed-length cold shear is upper-cut, the shear force is 5 kN, blade width is 950 mm, shear times are 10 times per minute

The reheating furnace is a three-stage continuous pusher-type reheating furnace with an effective size of 8400mm *18096mm, a

single row of feed, coke oven gas as fuel, and a design capacity of 80t/h.

Roughing Mill

The roughing mill consists of six flat-vertical short stress mills arranged alternately. The nominal diameter of the roll is

550mm, and the length of the roll body is 760 mm. The range of application is 610 mm to 520 mm.

There is a crank flying shear at the exit of rough rolling mill. The maximum cross-section is 4000mm. It is used to cut the head

and tail of the rolled piece after rough rolling and to break the rolled piece in case of an accident.

Intermediate Rolling Mill

The intermediate rolling mill is composed of six short stress mills arranged alternately by horizontal and vertical mills without

archway. The nominal diameter of the roll is 400 mm, and the length of the roll body is 650 mm. The range of application is 430 mm

to 370 mm.

There is a crank flying shear at the exit of the medium rolling mill. The maximum section of the shear is 2050 mm. It is used for

cutting the head and tail of the rolled piece after medium rolling and breaking the rolled piece in case of an accident.

Finishing Mill

The finishing mill consists of three flat, one vertical and two flat-vertical convertible short stress mills without archway. The

nominal diameter of the roll is 350 mm, and the length of the roll body is 650 mm. The range of application is 370 mm to 310 mm.

The finishing mill is equipped with a crank rotary changeable flying shear with a maximum shear section of 1300 mm and a length of

45 m to 72.

Bar Rolling Mill Cooling Bed

The cold bed is a stepping rack type with an area of 8m*78m, a rack spacing of 300mm/600mm, a pitch of 80mm and a working period

of less than 2.8s.

Fixed Length Cold Shear

Fixed-length cold shear is upper-cut, the shear force is 5 kN, blade width is 950 mm, shear times are 10 times per minute

Recommend Products

Packing & Shipping

Hot Searches