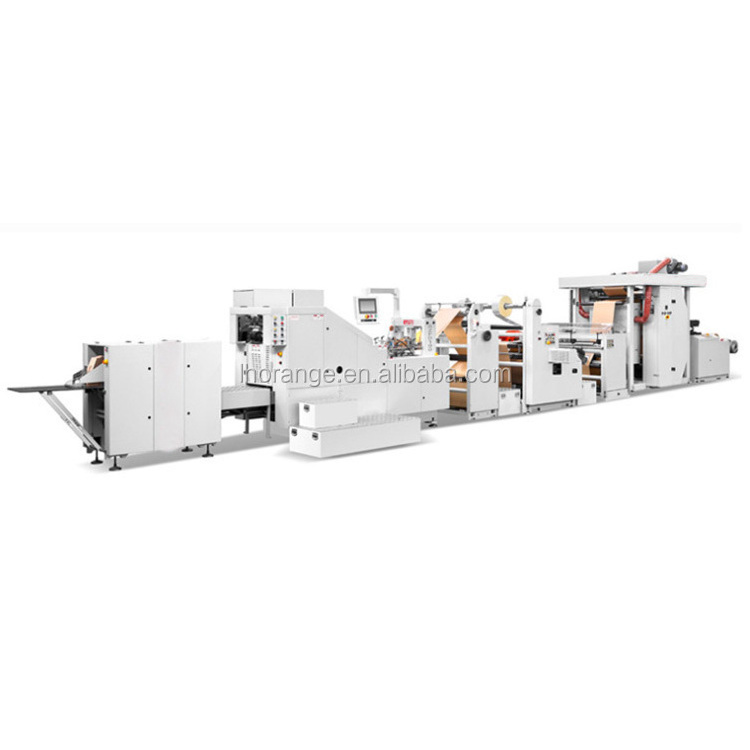

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ORANGE BRAND

-

Model Number:

-

ORZDJ-250

-

Voltage:

-

380V

-

Weight:

-

2500KG

-

Application:

-

Supermarket

-

After-sales Service Provided:

-

1 Year, Online support, Video technical support

-

Type:

-

General

-

Usage:

-

Paper Forming Machine

-

Processing Type:

-

Heat Sealing Hot Cutting

-

Function:

-

Cutting Roll

-

Color:

-

Customer Requirement

-

Feature:

-

Advanced Technology

-

Type of bag:

-

Cement Flour Bag

-

Kind:

-

Paper Bag Making Machine Cost

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Shopping Bag

-

Material:

-

Paper

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ORANGE BRAND

-

Model Number:

-

ORZDJ-250

-

Voltage:

-

380V

-

Weight:

-

2500KG

-

Application:

-

Supermarket

-

After-sales Service Provided:

-

1 Year, Online support, Video technical support

-

Type:

-

General

-

Usage:

-

Paper Forming Machine

-

Processing Type:

-

Heat Sealing Hot Cutting

-

Function:

-

Cutting Roll

-

Color:

-

Customer Requirement

-

Feature:

-

Advanced Technology

-

Type of bag:

-

Cement Flour Bag

-

Kind:

-

Paper Bag Making Machine Cost

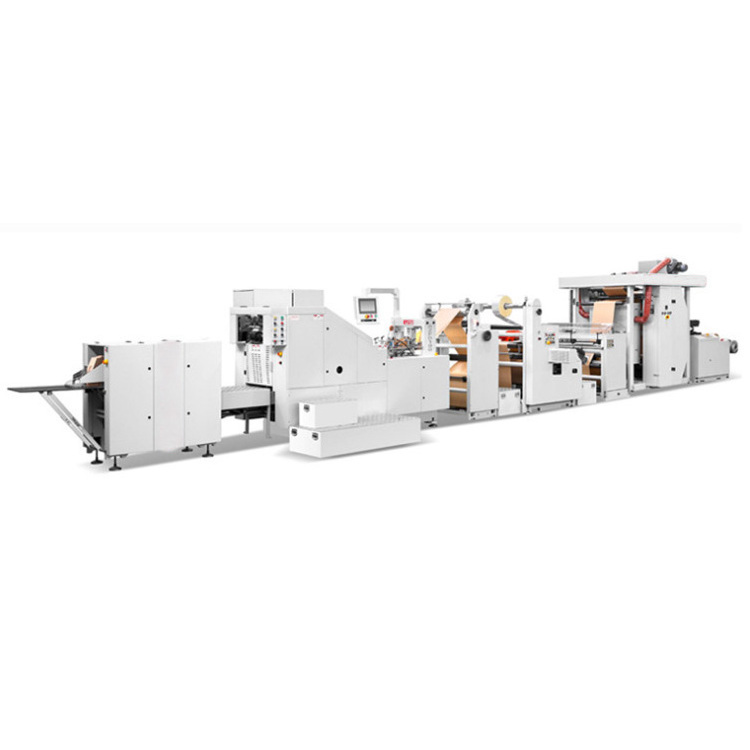

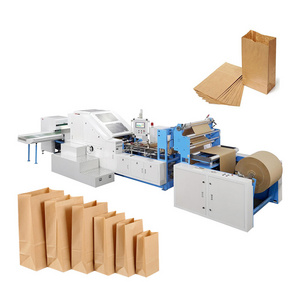

Main features

1. Using the French SCHNEIDER touch screen man-machine interface, operating at a glance, easy to control.

2 .Using the h British TRIO n Motion r Controller (PC), through the integration with the optical fiber to ensure high-speed operation and stability.

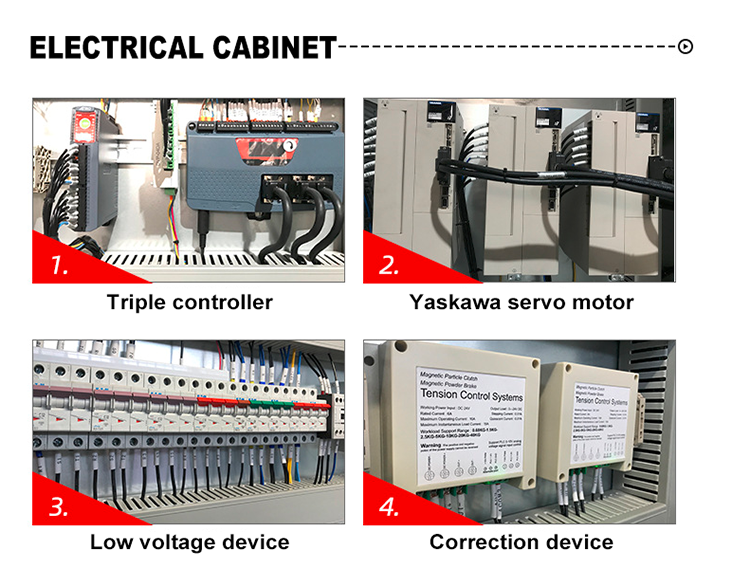

3 .Using the Japanese l Original YASKAWA servo motor with the German original

SICK photoelectric eye correction, accurate tracking printing bag size.

4 .The raw material loading and unloading adopts the pneumatic cylinder

lifting structure, the roll adopts the full automatic constant tension control.

5 .Raw materials China correction using n Taiwan e Pasource , , reduce the roll

adjustment time alignment.

Product advantages

1. Food packaging grade kraft paper can directly contact with food, which is clean and sanitary.

2. The paper is equipped with automatic pneumatic device, which is convenient to switch and does not need manual operation.

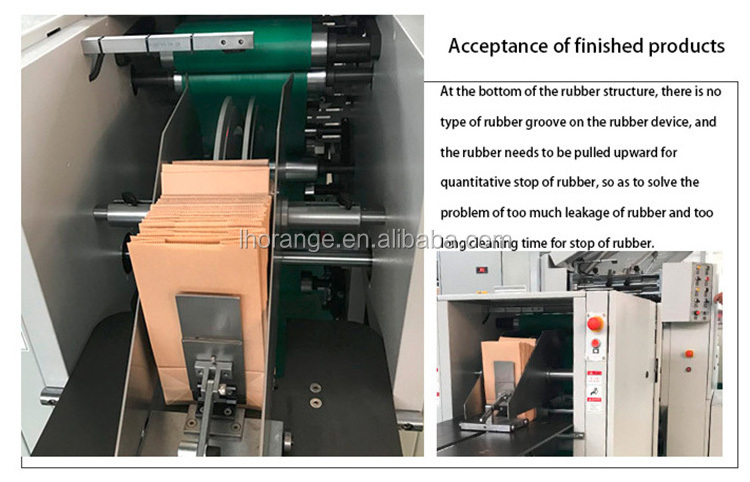

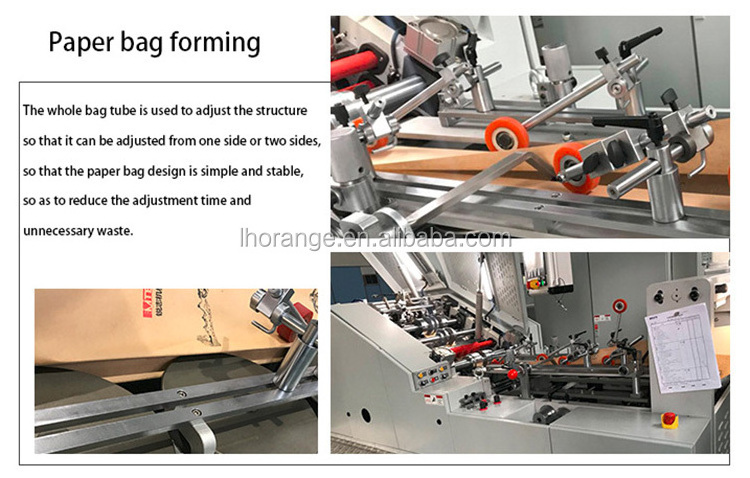

3. The whole bag tube is used to adjust the structure of the paper bag forming, so that it can be adjusted from one side or two sides, so that the design of the paper bag is simple and stable.

4. The servo motor is used to control the length of the paper bag at the bottom of the bag, and the tooth cutter rotates evenly at high speed to punch holes, so as to ensure the uniform and beautiful cut.

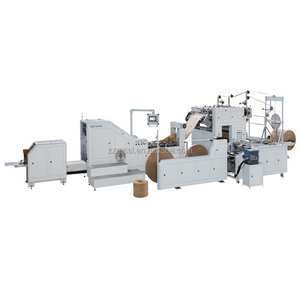

Product parameters

|

Product model |

Product model |

Product parameters |

|

|

ORZDJ-250

|

Sharp Bottom Paper Bag Machine ( No handle )

|

Type |

Paper Bag Machine |

|

Motor power |

17 (KW) |

||

|

Bag length |

10 0 -45 0(mm) |

||

|

Bag width |

70 -2 5 0 (mm) |

||

|

Machine speed |

50 -3 50pcs/min |

||

|

Paper feed width |

100 -78 0 (mm) |

||

|

Paper diameter |

200-1000(mm) |

||

|

Paper material thickness |

5-80g / m 2 |

||

|

Voltage |

380V |

||

|

Boundary dimension |

7100x3000x2200(mm) |

||

|

weight |

4500 (kg) |

||

|

Bag making material |

Kraft paper |

||

|

Place of Origin |

China |

||