- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

3000 KG

-

Dimension(L*W*H):

-

25000*1500*2200

-

Year:

-

2023

-

item:

-

puffed corn snacks making machine

-

Function:

-

Producing Pet Puffed Food

-

Final product:

-

ball, stick, flower, core filling snack, etc.

-

type:

-

puff snack machine

-

Raw material:

-

corn flour, wheat flour, rice flour, etc.

-

Color:

-

Stainless Steel Color

-

Suitable for:

-

Snack Food Processing Plant

-

Product:

-

Pet Food Production Line Dog Food Making Machine

-

Usage:

-

Snack Food Processing Plant

-

Advantage:

-

Easy Operation High Performance

Quick Details

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V/440v

-

Power:

-

55kw

-

Weight:

-

3000 KG

-

Dimension(L*W*H):

-

25000*1500*2200

-

Year:

-

2023

-

item:

-

puffed corn snacks making machine

-

Function:

-

Producing Pet Puffed Food

-

Final product:

-

ball, stick, flower, core filling snack, etc.

-

type:

-

puff snack machine

-

Raw material:

-

corn flour, wheat flour, rice flour, etc.

-

Color:

-

Stainless Steel Color

-

Suitable for:

-

Snack Food Processing Plant

-

Product:

-

Pet Food Production Line Dog Food Making Machine

-

Usage:

-

Snack Food Processing Plant

-

Advantage:

-

Easy Operation High Performance

Multi-function Rice Puffed Corn Snack Machines Corn Puff Screw Extruder Machine Snack Food Making Machine

pop snack extruder machine Snacks Food Processing Line is a new type of extruding food processing line studied and developed by ourselves on the basis of learning from advanced technology in the world so that its technical performance and quality of products both reach to the most advanced in the world. This line will finish mixing, extruding, shaping, core-filling, cutting, spraying and producing in one-pass operation automatically. This line features lots of types, flexible collocation, extensive applied materials, various products and easy operation.

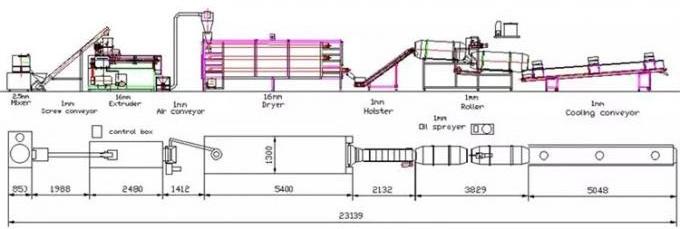

2.Work flow chart

Flour Mixer---Screw Conveyer---Double Screw Extruder---Core Filler---Multi-function Shaper---Hoister---Multi-layer Oven---Flavorig Machine

3. Snacks Puff Food extruder Machine Details

1) Alloy (38CrMoAL) screw made by nitriding process, high strength and wear-resting. Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials.

2)Adopting speed adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process.

3)Gearbox with automatic lubrication function, extending gear life.

4) World famous brand Siemens main motor, guaranteeing good quality

5)Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely.

6)Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

4.Raw Material:

Wheat flour, potato starch, potato flour, corn starch, cassava starch, etc.

5.Technical parameters of snack extrude machine

|

Model |

Installed Power |

Main Motor Power |

Output |

Dimension |

|

PF-65 |

34kw |

22kw |

120-150kg/h |

3100*930*1850mm |

|

PF- 65L |

47kw |

30kw |

180kg/h |

3500*950*1850mm |

|

PF- 70 |

53kw |

37kw |

200-250kg/h |

3200*760*2000mm |

|

PF- 70L |

53kw |

37kw |

200-250kg/h |

3200*930*2000mm |

|

PF- 85 |

99kw |

75kw |

500kg/h |

3800*1100*2350mm |

|

PF- 85L |

101kw |

90kw |

800-1000kg/h |

5420*2300*2900mm |

|

PF- T75 |

75KW |

98KW |

300-500KG/H |

5200*1100*2800mm |

|

PF- 95 |

110KW |

142KW |

600-1200kg/ |

6400*3000*3000mm |

1. What is corn puff snack extruder?

Puff Snack Process Line adopts advanced share exrtrusion technology, which can extrude products with different textures and tastes out of Double-Screw Extruder at the same time. It can produce a variety of direct puff snack food which are popular in the world market, such as fragrant chicken, core-filling rolls,etc.It can produce 24-hour continuously.Moulds and hopper are both non-sticky processed.All the parts that contact food are nontoxic

material,oil and high temperatureresistance.