- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.34%

-

CrO Content (%):

-

0.1-0.3%

-

SiC Content (%):

-

1.2-1.4

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

TKHAB

-

Brand Name:

-

TK BRICKS

-

Product name:

-

High Alumina Brick

-

Apparent porosity:

-

≤23%

-

Refractoriness(SK):

-

30-40

-

Crushing strength:

-

40~60 Mpa

-

Standard size:

-

230 x 114 x 65mm

-

Special size:

-

customer's drawing

-

Bulk density g/cm3:

-

2.00-2.35

-

Permanent Linear Change@1400℃X2:

-

±0.2~±0.3

-

Refractoriness under load at 0.2MPa:

-

1380~1550℃

-

Fe2O3:

-

1.8%~2.0%

Quick Details

-

SiO2 Content (%):

-

-

-

Al2O3 Content (%):

-

48%-85%

-

MgO Content (%):

-

0.8-1.2

-

CaO Content (%):

-

0.34%

-

CrO Content (%):

-

0.1-0.3%

-

SiC Content (%):

-

1.2-1.4

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

TKHAB

-

Brand Name:

-

TK BRICKS

-

Product name:

-

High Alumina Brick

-

Apparent porosity:

-

≤23%

-

Refractoriness(SK):

-

30-40

-

Crushing strength:

-

40~60 Mpa

-

Standard size:

-

230 x 114 x 65mm

-

Special size:

-

customer's drawing

-

Bulk density g/cm3:

-

2.00-2.35

-

Permanent Linear Change@1400℃X2:

-

±0.2~±0.3

-

Refractoriness under load at 0.2MPa:

-

1380~1550℃

-

Fe2O3:

-

1.8%~2.0%

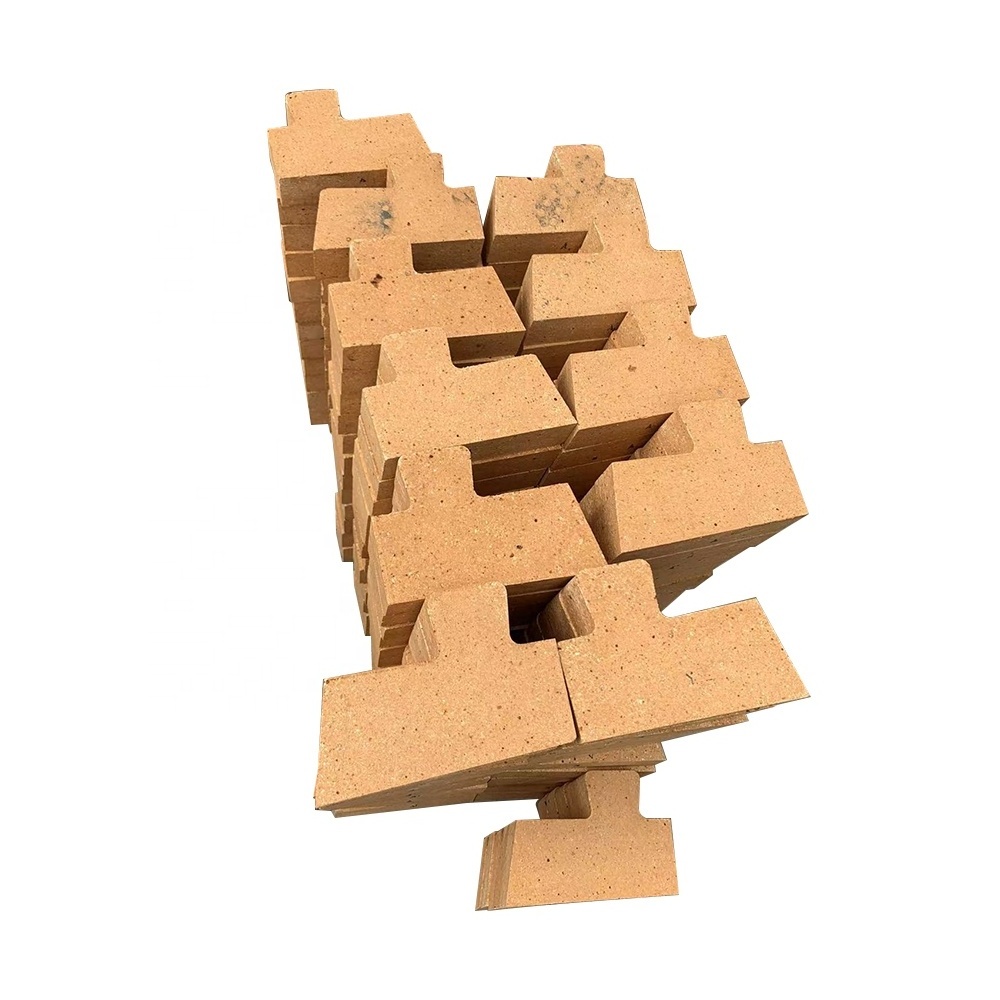

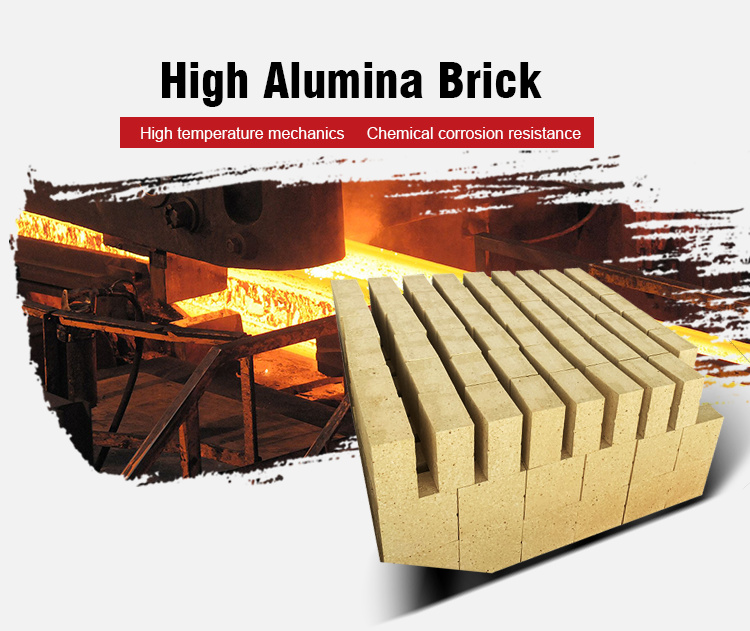

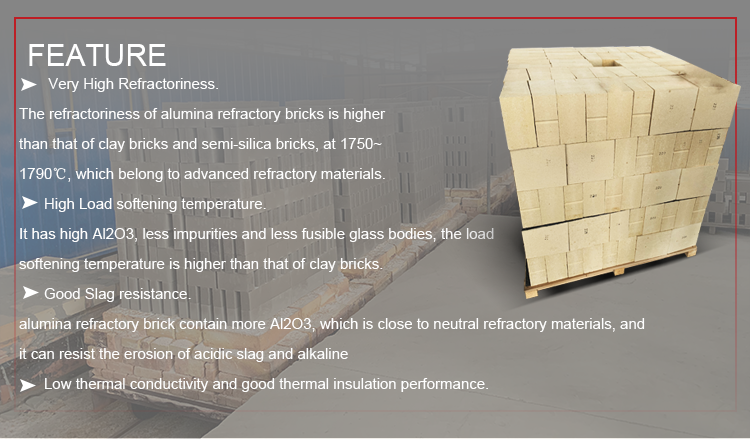

High Temperature Anti-Spalling High Alumina Refractory Curved Fire Resistant Brick

TK BRICKS high alumina bricks are produced with selected bauxite chamotte by advanced process and strict quality control. It is an aluminum silicate refractory product with aluminum oxide (Al2O3) content higher than 48%. The main component of this refractory brick is AL2O3.It features excellent high temperature mechanics and chemical corrosion resistance.

|

Brick Standard Sizes

|

|

|

|

|

|

|||||

|

SPLITSTRAIGHT

L×W×H(mm)

|

SPLIT

L×W×H(mm)

|

ARCH

L×W×H(mm)

|

WEDGE

L×W×H(mm)

|

TILE

L×W×H(mm)

|

OTHER SHAPE

|

|||||

|

230×114×65

|

230×114×25

|

230×114×65/45

|

230×114×65/45

|

230×230×38

|

Key brick

|

|||||

|

230×114×75

|

230×114×32

|

230×114×65/55

|

230×114×65/55

|

230×230×50

|

Skew brick

|

|||||

|

|

230×114×37

|

230×114×75/45

|

220×114×75/45

|

230×230×65

|

Soap

|

|||||

|

|

230×114×50

|

230×114×75/55

|

220×114×75/55

|

230×230×75

|

Checker

|

|||||

|

|

≤10

|

230×114×75/65

|

220×114×75/65

|

|

Neck

|

|||||

|

|

|

|

|

|

Taper

|

|||||

|

Technical Data Sheet of alumina refractory bricks.

|

|

|

|

|

|

|||||

|

Grade

|

SK-32

|

SK-34

|

SK-36

|

SK-38

|

SK-40

|

|||||

|

Al2O3/%

|

48

|

55

|

65

|

75

|

80

|

|||||

|

Fe2O3/%

|

≤3

|

≤3

|

≤1.8

|

≤1.6

|

≤1.5

|

|||||

|

Refractoriness/ ℃

|

≥1770

|

≥1770

|

≥1770

|

≥1790

|

≥1790

|

|||||

|

Bulk density/g/cm3

|

2.15-2.25

|

2.25-2.35

|

2.35-2.45

|

2.45-2.65

|

2.65-2.75

|

|||||

|

Apparent porosity/%

|

≤24

|

≤23

|

≤23

|

≤22

|

≤21

|

|||||

|

Cold crushing strength/Mpa

|

≥35

|

≥40

|

≥45

|

≥55

|

≥60

|

|||||

|

Refractoriness under load 0.2Mpa / ℃

|

≥1300 °C

|

≥1350 °C

|

≥1400 °C

|

≥1490 °C

|

≥1530 °C

|

|||||

|

Reheating Linear Change/%

|

+0.1~-0.4

(1350°C,2h)

|

+0.1~-0.4

(1350°C,2h)

|

+0.1~-0.4

(1450°C,2h)

|

+0.1~ -0.4

(1450°C,2h)

|

|

|||||

Hot Searches