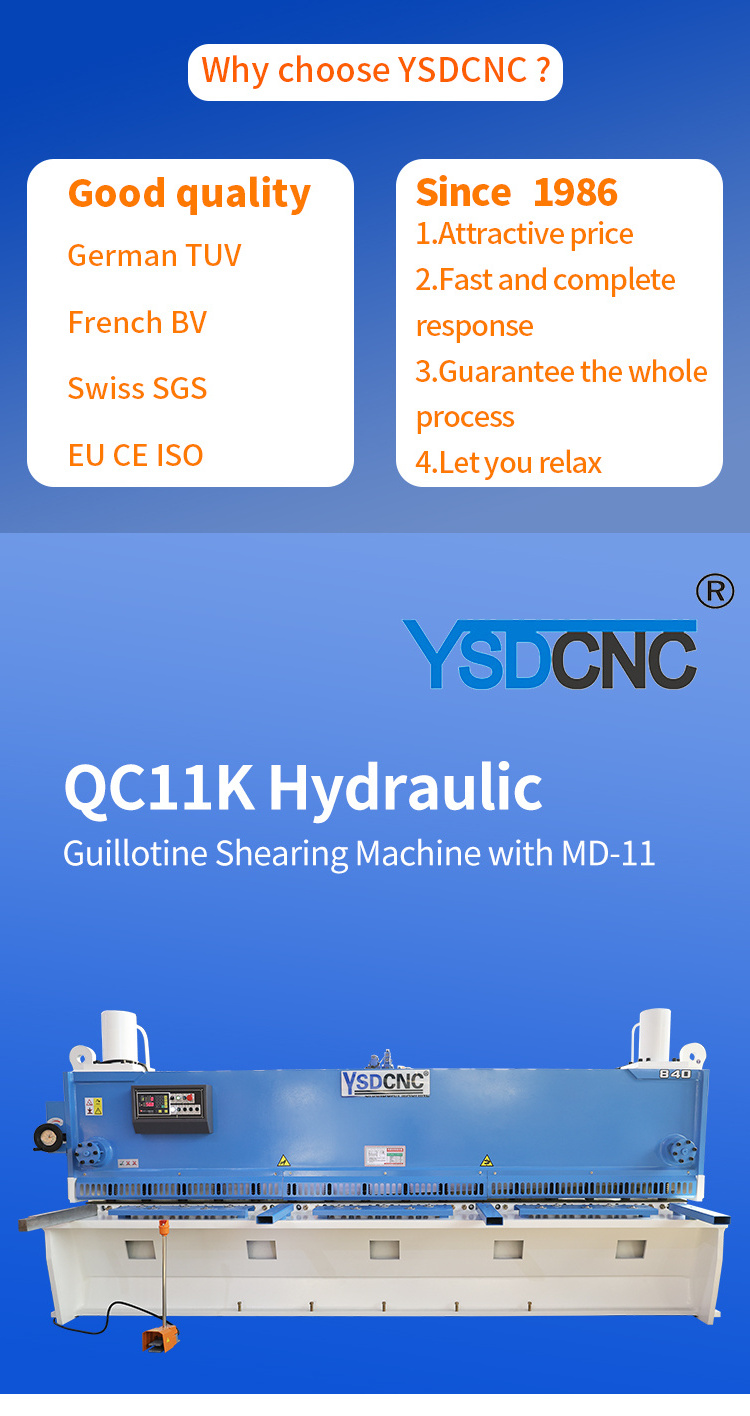

- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

6200 mm

-

Backgauge Travel (mm):

-

20 - 600 mm

-

Throat Depth (mm):

-

300 mm

-

Brand Name:

-

ysdcnc

-

Power (kW):

-

11 kW

-

Weight (KG):

-

18000 KG

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

4700*1800*2480mm

-

Year:

-

2024

-

Marketing Type:

-

Hot Product 2024

-

Product name:

-

Heavy Duty Automatic CNC hydraulic guillotine shearing Machine

-

Model Number:

-

QC11K-8*4000

-

shear plate thickness:

-

4-50 mm

-

shear plate width:

-

1600-12000 mm

-

numbers of strokes:

-

30times/min

-

Application:

-

Industrial Metal Cutting

-

Keyword:

-

Hydrualic Shearing Machine

-

Hydraulic system:

-

BOSCH hydraulic system

-

Control system:

-

Estun E21 NC Control

-

Quality standard:

-

German Standard

Quick Details

-

Max. Cutting Width (mm):

-

4000

-

Max. Cutting Thickness (mm):

-

8 mm

-

Shearing Angle:

-

2.14 degree

-

Blade Length (mm):

-

6200 mm

-

Backgauge Travel (mm):

-

20 - 600 mm

-

Throat Depth (mm):

-

300 mm

-

Brand Name:

-

ysdcnc

-

Power (kW):

-

11 kW

-

Weight (KG):

-

18000 KG

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

4700*1800*2480mm

-

Year:

-

2024

-

Marketing Type:

-

Hot Product 2024

-

Product name:

-

Heavy Duty Automatic CNC hydraulic guillotine shearing Machine

-

Model Number:

-

QC11K-8*4000

-

shear plate thickness:

-

4-50 mm

-

shear plate width:

-

1600-12000 mm

-

numbers of strokes:

-

30times/min

-

Application:

-

Industrial Metal Cutting

-

Keyword:

-

Hydrualic Shearing Machine

-

Hydraulic system:

-

BOSCH hydraulic system

-

Control system:

-

Estun E21 NC Control

-

Quality standard:

-

German Standard

Product Description

1. Quick cutting length adjustment

2. Optional CNC front feeding table

3. Optional rear pneumatic sheet supporter

4. Cutting angle and blade gap with Electric control

5. MD-11 with backguage sequence repeat and distance control

6. Upper and lower Guillotine shear blades with

four-side cutting edges

Features:

QC11K Hydraulic Guillotine Shearing Machine with MD-11 adopts all-steel welded structure and comprehensive treatment (vibration aging, heat treatment) to eliminate internal stress, with good rigidity and stability. X axis(Backgauge) and cutting time can be programmed by MD-11 system controller, which can store up to 40 groups of programs. Advanced integrated hydraulic system with high reliability. Three points of support rolling guide are used to eliminate the support gap and improve the shearing quality. Blade gap adjustment by hand wheel or electric, quick, accurate and convenient. Rectangular blade with all four edges, long service life. Upper blade holder with inward tilting structure, easy to drop the material and improve the accuracy of the workpiece. Segmented shearing function with light alignment.

QC11K Hydraulic Guillotine Shearing Machine with MD-11

The streamlined welded machine structure achieves high

rigidity; the machine is designed by ANSYS software

which can ensure the reliability and precision of the

shearing machine.

Details Products

Front Arm

Roller ball is instACalled on the arm with ruler can reduce the abrasion and feeder the machine easily and accurately.

KACON Foot Switch

South Korea brand food switch is

movable and can stop the machine anytime by the emergency button

Open Door Power off Switch

The machine will stop immediately once worker opens the door electric Cabinet.

Motorized blade

clearance adjustment

Adjust the cutting blades gap by motor according the cutting thickness of the metal sheet can get better cutting Performance.

Cutting Blade

Safety Fence

HIWIN Ball Screw

Adjust Backgauge up and down.

Rexroth Valve

World famous brand REXROTH, Sub-brand of BOSCH, which is the professional hydraulic valve supplier.

SIEMENS Motor

German famous brand motor improves the lifespan of the machine and keeps the machine working in low noise environment.

SUNNY Pump

Schneider Electric Components

High quality electric parts can perform well even the electricity is not stable and customers can easily get the replacement anywhere in the word.

BACKGAUGE MOTOR

The backgauge motor is step motor.

Frequency Inverter

The motors for backgauge stroke are controlled by inverter, which can achive high positioning accuracy of the backguage.

HYDRAULIC HOLD- DOWN PADS

The lower end of the press cylinder is made of non-metal material,which has certain elasticity and large friction coefficient.

When cutting the sheet,the press pad can be in close contact with the material plate to provide sufficient friction to effectively prevent the plate from being shaken during the shearing process.

Pneumatic Back Support

Light Curtain

Front Feeding Table

Feeding the metal sheet automatically controlled by CNC controller with high precision and efficiency.

Specification

|

Model

|

Shearing

Thickness (mm) |

Shearing

Width (mm) |

Stroke

Times (cuts/min) |

Back-gauge

Rang (mm) |

Shearing

Angler(°) |

Main

Power (KW) |

Overall

Dimensions (L×W×H)(mm) |

|

4×2500

|

4

|

2500

|

16~35

|

20~600

|

30’~1°30’

|

5.5

|

3200×1400×2000

|

|

6×2500

|

6

|

2500

|

16~35

|

20~600

|

30’~1°30’

|

7.5

|

3200×1500×2100

|

|

6×3200

|

6

|

3200

|

14~35

|

20~600

|

30’~1°30’

|

7.5

|

3900×1580×2150

|

|

6×4000

|

6

|

4000

|

10~30

|

20~600

|

30’~1°30’

|

7.5

|

4700×1650×2250

|

|

6×5000

|

6

|

5000

|

10~30

|

20~800

|

30’~1°30’

|

11

|

5700×1800×2380

|

|

6×6000

|

6

|

6000

|

8~25

|

20~800

|

30’~1°30’

|

11

|

6700×2000×2650

|

|

8×2500

|

8

|

2500

|

14~30

|

20~600

|

30’~2°

|

11

|

3200×1550×2150

|

|

8×3200

|

8

|

3200

|

12~30

|

20~600

|

30’~2

|

11

|

3950×1750×2350

|

|

8×4000

|

8

|

4000

|

10~25

|

20~600

|

30’~2°

|

11

|

4700×1800×2480

|

|

8×5000

|

8

|

5000

|

10~25

|

20~800

|

30’~2°

|

15

|

5700×1950×2600

|

|

8×6000

|

8

|

6000

|

8~20

|

20~800

|

30’~2°

|

15

|

6700×1980×2650

|

|

12×2500

|

12

|

2500

|

12~25

|

20~800

|

30’~2°

|

15

|

3250×1680×2250

|

|

12×3200

|

12

|

3200

|

12~25

|

20~800

|

30’~2°

|

15

|

3980×1800×2550

|

|

12×4000

|

12

|

4000

|

8~20

|

20~800

|

30’~2°

|

15

|

4800×1950×2650

|

|

12×5000

|

12

|

5000

|

8~20

|

20~1000

|

30’~2°

|

22

|

5800×2150×2700

|

|

12×6000

|

12

|

6000

|

6~20

|

20~1000

|

30’~2°

|

30

|

6800×2450×2900

|

|

16×2500

|

16

|

2500

|

12~20

|

20~800

|

30’~1°30’

|

22

|

3280×1830×2520

|

|

16×3200

|

16

|

3200

|

12~20

|

20~800

|

30’~1°30’

|

22

|

3950×1950×2650

|

|

16×4000

|

16

|

4000

|

8~15

|

20~800

|

30’~1°30’

|

22

|

4800×1970×2700

|

|

16×5000

|

16

|

5000

|

8~15

|

20~1000

|

30’~1°30’

|

30

|

5800×2250×2870

|

|

16×6000

|

16

|

6000

|

6~15

|

20~1000

|

30’~1°30’

|

37

|

6800×2450×3150

|

|

20×2500

|

20

|

2500

|

10~20

|

20~800

|

30°~3°

|

30

|

3400×2260×2520

|

|

20×3200

|

20

|

3200

|

10~20

|

20~800

|

30’~3°

|

30

|

4100×2300×2700

|

|

20×4000

|

20

|

4000

|

8~15

|

20~800

|

30’~3°

|

30

|

4900×2500×2880

|

|

20×5000

|

20

|

5000

|

8~15

|

20~1000

|

30’~3°

|

37

|

5900×2750×2980

|

|

20×6000

|

20

|

6000

|

6~15

|

20~1000

|

30’~3°

|

37

|

6900×2850×3200

|

|

25×2500

|

25

|

2500

|

8~15

|

20~800

|

30’~3°

|

37

|

3420×2400×2650

|

|

25×3200

|

25

|

3200

|

8~15

|

20~800

|

30’~1°30’

|

37

|

4150×2500×2750

|

|

25×4000

|

25

|

4000

|

6~12

|

20~1000

|

30’~1°30’

|

37

|

4900×2600×2950

|

|

30×2500

|

30

|

2500

|

8~12

|

20~1000

|

30’~1°30’

|

55

|

3450×2600×2750

|

|

30×3200

|

30

|

3200

|

8~12

|

20~1000

|

30’~4°

|

55

|

4150×2700×2850

|

|

30×4000

|

30

|

4000

|

8~12

|

20~1000

|

30’~4°

|

55

|

4900×2900×3100

|

|

40×2500

|

40

|

2500

|

4~10

|

20~1000

|

30’~4°

|

55

|

4000×2950×3150

|

|

40×3200

|

40

|

3200

|

4~10

|

20~1000

|

30’~4°

|

55

|

4900×3050×3680

|

Our Service

1:The machine provides 36-month warranty and free online support and service from engineers.

2: Provide online technical support

and service for life, even after the warranty period, the engineer team can always provide you with online service at no additional cost. (All our clients have this service, we think it is very necessary)

3: During the warranty period, we can send you spare parts for free replacement.

4: After the machine is completed, free whatsapp online inspection service will be provided.Bend the product according to your requirements, then test it.

5: Pack and record the video, and submit it to you for acceptance service, or you can directly watch online on whatsapp.

6: We can also provide the following information, and it is very necessary.photo of the rating plate you apply on the machine itself-basic manual for the machine in English.

and service for life, even after the warranty period, the engineer team can always provide you with online service at no additional cost. (All our clients have this service, we think it is very necessary)

3: During the warranty period, we can send you spare parts for free replacement.

4: After the machine is completed, free whatsapp online inspection service will be provided.Bend the product according to your requirements, then test it.

5: Pack and record the video, and submit it to you for acceptance service, or you can directly watch online on whatsapp.

6: We can also provide the following information, and it is very necessary.photo of the rating plate you apply on the machine itself-basic manual for the machine in English.

We are a 7-year member of Alibaba, and we

support third-party guarantee transactions of

Alibaba credit insurance transactions, which

can better protect your financial security.

The company provides a variety of transaction

methods: EXW, FOB, CIF, DDU, DDP and other

education methods support customs declaration,

export, transportation and delivery to the door

and other one-stop services.

You can trade through TT, wire transfer,

transfer, paypel, letter of credit, Alibaba

credit order and other transaction methods.

We can deliver to your forwarding warehouse, or

directly to your door, and deliver the goods to

your hands.We cooperate with well-known

international shipping companies such as

COSCO Shipping, and we can also be responsible

for the customs clearance of your goods, delivery

of goods to your door, etc.And we provide free

shipping insurance. If there is any damage during

transportation, our insurance company will settle

the claim for you, and we will send you free

shipping. (If you have any questions, please

contact us as soon as possible, and we will guide

you how to operate? We are your most trusted

partner, we are your eyes and hands.)

Our Company

Nanjing Shanduan CNC Machine Tool Co., Ltd. has 38

years of industry experience. We specialize in four main

product lines: air duct production lines, CNC bending machines, shearing machines, laser cutting machines, and shredders

for energy recovery. With over 300 employees, including 30

sales engineers and 35 service engineers, our factory spans

40 acres and is equipped with 3 floor-type boring and milling

machines, 6 gantry planers, 10 radial drilling machines, and

25 CNC machining centers. In total, we have over 200 large

and small-scale equipment.

With over 100,000 customer case experiences and product transportation to over 100 countries, we have a proven track

record in serving a wide range of clients. We are dedicated to assisting you in securing orders and providing high-quality

products and services. Our commitment to excellence has

resulted in many satisfied customers who are eager to

become our agents.

FAQ

Is it in stock?

Hello, we have a large amount of stock for standard models, and the regular delivery time is 0~7 days.

Customized models can be completed in 7-30 days (depending on the size and voltage of the machine, the time is different.)

How to buy?

Our company supports a variety of transaction methods, and you can deliver the goods to your door with a deposit in advance.Various transaction methods such as payment to delivery or delivery to the factory. Consult for details: +8618851629789

How about the after-sales service?

15 minutes quick feedback mechanism.

1-to-1 technical guidance.

One year warranty and lifetime service.

Free replacement of non-wearing parts during the warranty period, and lifelong online technical support provided outside the warranty period.

The factory provides spare parts, and the factory installation video provides after-sales service.

How about your quality?

Our company's products are produced according to national standards, and have passed TUV, SGS, BV, CE and other certifications.

Quality assurance, EU approval, the products sell well in more than 100 countries.

What other services do you have?

Free counter, free customs declaration, free installation training for export, free online technical guidance.

Hot Searches