Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 years

-

Brand Name:

-

HRZL

-

Model Number:

-

HR-QW-200-4

-

Place of Origin:

-

SHANDONG, CHINA

-

Horsepower:

-

0.37KW~74KW---0.28HP~100HP

-

Power:

-

0.37KW~74KW---0.28HP~100HP

-

Product name:

-

1.5HP High Pressure Sewage Pump

-

Type:

-

Centrifugal Pump

-

Structure mode:

-

Single-stage Pump

-

Driver:

-

Electric motor

-

Head:

-

5.6~330M

-

Power Space:

-

220v/240v/380/415v can be customized.

-

Maximum drivr ratinbg:

-

0.37KW~280KW---0.28HP~210HP

-

Temperature:

-

-20℃~80℃

-

Certification:

-

Other,ISO9001,CQC,CCCF

Quick Details

-

Application:

-

Biofuel Industry, Food and Beverage Industry, Industrial Utilities, Irrigation and Agriculture, Machining, Mining industry, Pharmaceutical industry, Washing and Cleaning

-

Pressure:

-

≤4.0MPa

-

Voltage:

-

220v/240v/380/415v can be customized.

-

Warranty:

-

1 years

-

Brand Name:

-

HRZL

-

Model Number:

-

HR-QW-200-4

-

Place of Origin:

-

SHANDONG, CHINA

-

Horsepower:

-

0.37KW~74KW---0.28HP~100HP

-

Power:

-

0.37KW~74KW---0.28HP~100HP

-

Product name:

-

1.5HP High Pressure Sewage Pump

-

Type:

-

Centrifugal Pump

-

Structure mode:

-

Single-stage Pump

-

Driver:

-

Electric motor

-

Head:

-

5.6~330M

-

Power Space:

-

220v/240v/380/415v can be customized.

-

Maximum drivr ratinbg:

-

0.37KW~280KW---0.28HP~210HP

-

Temperature:

-

-20℃~80℃

-

Certification:

-

Other,ISO9001,CQC,CCCF

1.5HP High Pressure Electric Automatic Grinding Sewage Submersible Pumps China Good Pump

QW series of non-clogging submersible sewage pumps is a new generation of products successfully developed by our company on the basis of introducing advanced foreign technology and combining the characteristics of domestic and foreign pumps. This series of products has the characteristics of design spectrum, wide performance coverage, high efficiency, anti-winding, no blockage, automatic coupling, high reliability, automatic control and automatic protection. The series of pumps and motor coaxial, compact structure, easy to maintain.

— — — — — —————— product parameters — — — — — — — — — — —

| Type | 1.5HP High Pressure Sewage Pump |

| Usage: | Sewage water |

| Main Applications: | River Sewage,Urban Sewage,Public Sewage,Domestic Sewage,Industrial Sewage, |

| Driver: | Electric motor |

| Power Space | 220v/240v/380/415v can be customized. |

| Temperature: | .-20℃~80℃ |

| Type of connection | Flange |

| Casing: | stainless steel can be customized. |

| Impeller Type: | Close Impeller |

| Shaft seal type: | Mechanical Seal |

| Maximum drivr ratinbg | 0.37KW~280KW---0.28HP~208HP |

| Maximum discharge-side pressure | ≤4.0MPa |

| maximum head | 5.6m~330m |

| Flow rate range | 0.83m³/h~10000m³/h---0.22L/S~2778L/S |

Performance Scope

1. Discharge of waste water seriously polluted by factory commerce

2. Civil air system drainage stations

3. Exploration, mine accessory machines

4. Municipal sewage treatment plant drainage system

5. Sewage from hospitals and hotels

6. Rural biogas digesters, farmland irrigation

7. Sewage stations in residential areas

8. Municipal works, construction sites

9. Water supply equipment for tap water

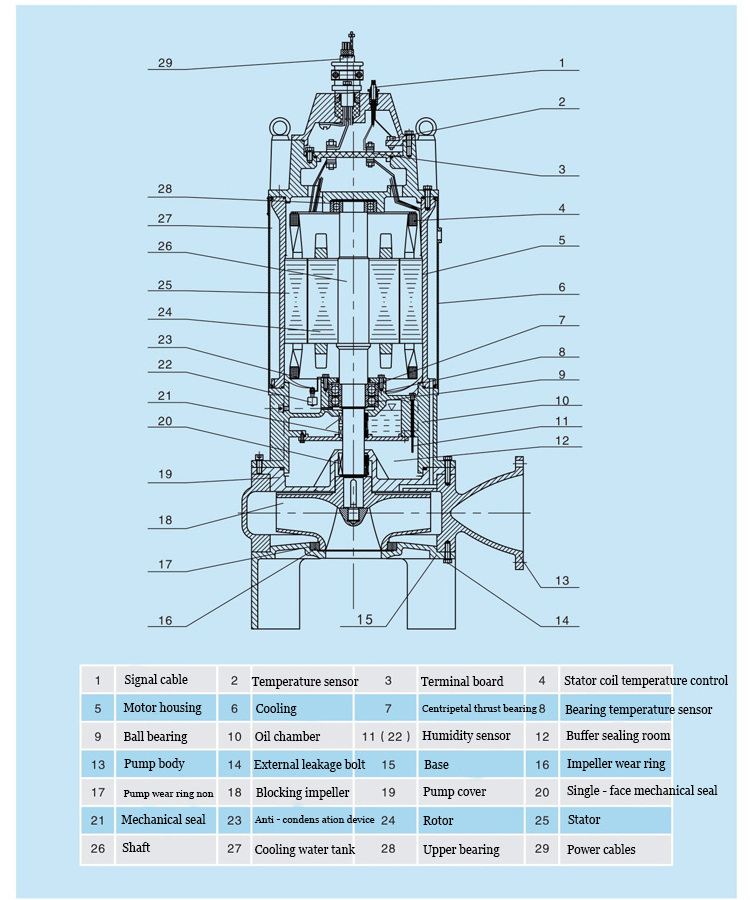

— — — — — ——-———— p roduct structure — — — — — — — — — — — —

Installation Instructions

1.QW series submersible drain pumps are fixed and mobile .Before

2.startup , the electric pump is damaged , fasten ers are loose or loose during transportation storage, etc.

3.Check the oil room for oil .

4.Check the imp eller is flexible before starting .The

5.checks whether the power supply unit is safe , reliable and normal .The supply voltage and frequency shall be specified (3 8 0 V/50Hz) .

6.Check whether the cable is damaged , broken , the inlet sealing of the junction box cable is intact, and timely handle it in case of possible leakage .

7.It is strictly forbidden to make the The cable of the pump is used as a sling to avoid danger. Measure electrical pump motor interphase and ground insulation resistance, its value should not be less than 1 MQ Otherwise, the motor stator winding resistance should be dried. Dry treatment

temperature is not allowed to exceed 120℃

8. after the pump turned on the direction of rotation: from the inlet to counter clock wise

— — — — — ——-———— p roduct details — — — — — — — — — — — —

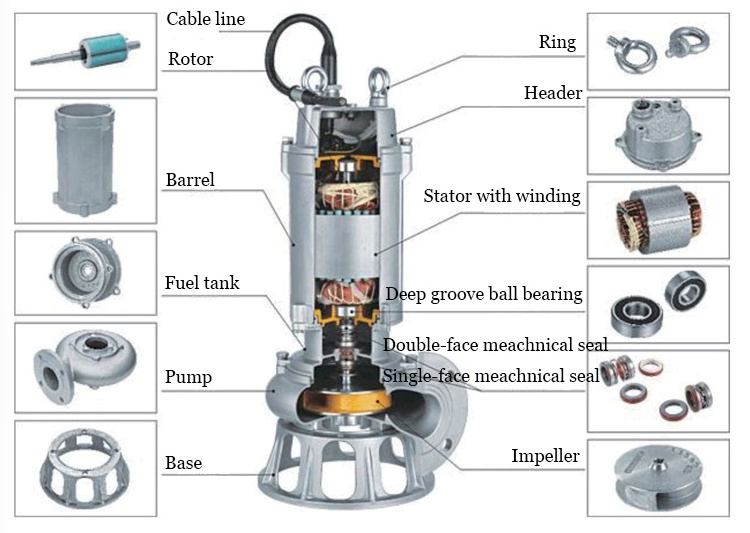

1.Impeller , with strong anti - winding and no - blockage performance, smooth operation after dynamic balance test ; smooth over current surface , large channel section , high efficiency and no blockage ;

2.Pump shell: pump shell is a single shell, distributed around the impeller to collect liquid; pump shell and impeller with easy to replace the wear-resistant ring;

3.Shaft: pump and motor coaxial, compact structure, shaft extension as short as possible, from the design to reduce deflection, running vibration, sealing and bearing life longer;

4.Sealing: two sets of independent mechanical seals, so that the motor and pump seal isolation; up and down series installation, provide double insurance, improve reliability;

5.Lubrication: Oil lubrication isol ates the motor from the delivered medium and acts as the cooler seal ;

6.Protective device: submersible sewage pump has multiple monitoring and protection devices, can lead the lead to the electronic control box. Protective devices include: overload, phase deficiency, leakage, overheating, humidity, immersion protection, etc

— — — — — —————— p roduct Parameter-- — — — — — — — — — — —

Only part of the product model parameters, please contact us for more information.