- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

2200 kg

-

Power (kW):

-

22

-

Product name:

-

Waste Crumb Rubber Tyre Shredder Recyle Machinery

-

Application:

-

Rubbers Recycling Industry

-

Quality:

-

High Level

-

Usage:

-

Used Tire Recyling

-

Advantage:

-

Easy Operation High Efficiency

-

Certification:

-

CE ISO TUV

-

Function:

-

Tire Powder Recycling Machine

-

Shredder Blade Material:

-

Cr12Mov

-

Capacity:

-

2-3tons

-

End product:

-

Rubber Particle

Quick Details

-

Place of Origin:

-

China

-

Model Number:

-

Aite

-

Voltage:

-

380V/50HZ or customized

-

Weight (KG):

-

2200 kg

-

Power (kW):

-

22

-

Product name:

-

Waste Crumb Rubber Tyre Shredder Recyle Machinery

-

Application:

-

Rubbers Recycling Industry

-

Quality:

-

High Level

-

Usage:

-

Used Tire Recyling

-

Advantage:

-

Easy Operation High Efficiency

-

Certification:

-

CE ISO TUV

-

Function:

-

Tire Powder Recycling Machine

-

Shredder Blade Material:

-

Cr12Mov

-

Capacity:

-

2-3tons

-

End product:

-

Rubber Particle

Product Overview

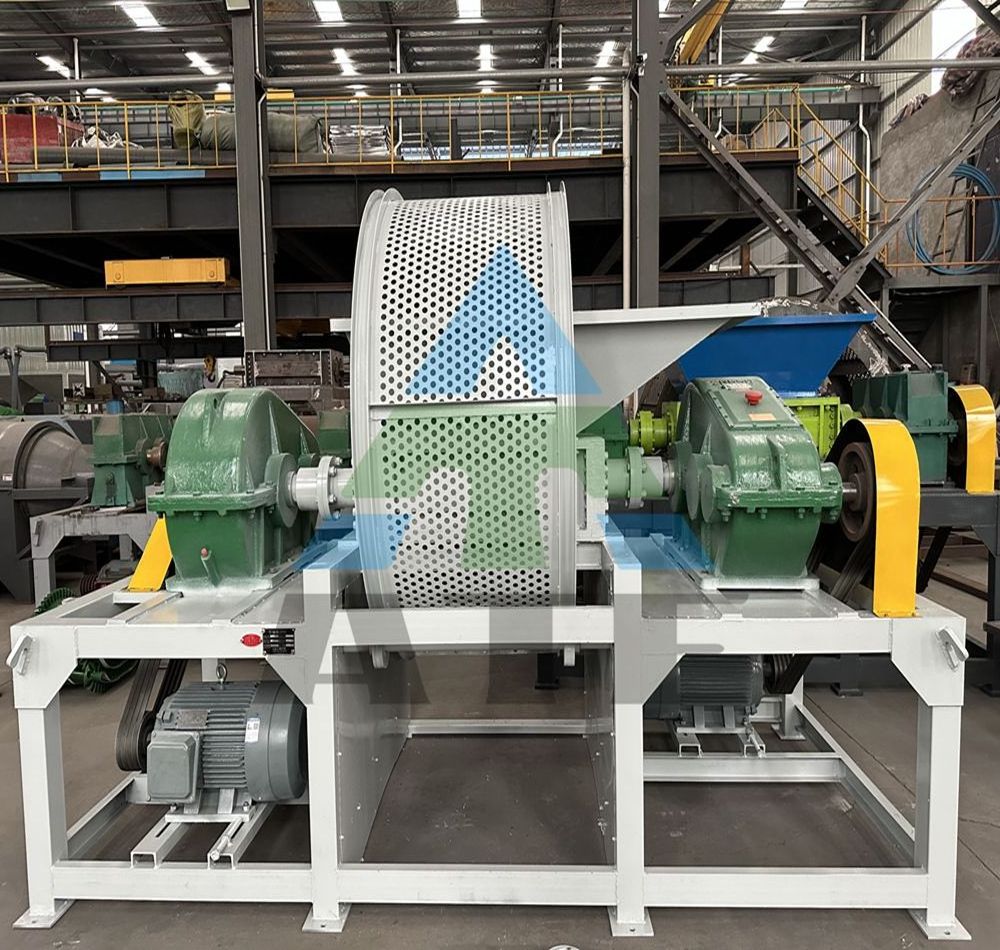

Waste Crumb Rubber Tyre Shredder Recyle Machinery/Tires Recycling Machine Production Line

Tyre Recycling Machine

Aite waste tyre recycling machine, is a rare in the whole of the EU CE certification with high standard of quality certification.

The whole tyre recycling machine line can effectively realize the automatic separation of rubber, steel wire, nylon fiber and

other materials, the whole line adopts PLC control system, it is easy to operate and maintain, and has the characteristics of

lowCenergy consumption and long service life.

Raw materials:

Waste tires, rubber soles, waste pipes, rubber conveyor belts and other waste rubber products, of which waste tires are the most.

We can customize metal crushing and recycling production line for you.

Aite waste tyre recycling machine, is a rare in the whole of the EU CE certification with high standard of quality certification.

The whole tyre recycling machine line can effectively realize the automatic separation of rubber, steel wire, nylon fiber and

other materials, the whole line adopts PLC control system, it is easy to operate and maintain, and has the characteristics of

lowCenergy consumption and long service life.

Raw materials:

Waste tires, rubber soles, waste pipes, rubber conveyor belts and other waste rubber products, of which waste tires are the most.

We can customize metal crushing and recycling production line for you.

Main Application

.

For different tire characteristics and productivity requirements,the line structure may include

1、Fully automatic wire drawing machine:remove tire steel wheel.

1、Fully automatic wire drawing machine:remove tire steel wheel.

2、Conveyor equipment:conveyor belt,screw conveyor and air pressure transmission system

3、Shredder:tear the tire into film (50mm-150mm).

4、Steel wire separator:separate the rubber and steel wire and

process it into rubber particles(10mm-20mm).

process it into rubber particles(10mm-20mm).

5、Magnetic separator:sorting steel wire from rubber wire mixture.

6、Crusher:Smash the rubber particles to a smaller size(1mm-7mm).

7、Vibrating screen:sorting different sizes of rubber particles,and returning the

oversized particles to the crusher for secondary crushing.

oversized particles to the crusher for secondary crushing.

8、Fiber separator:remove foreign matter and fiber.

9、Secondary Magnetic Separator:Possible Small Wires to Go.

10、Mill:The particles are ground to a powder (30 mesh to 100 mesh).

11、Fully automatic bagging system:loading finished products into storage bags or bags.

Our Advantage

1. Super high crushing efficiency

Hydraulic feeding, hammer throwing and ring hammer combined crushing hammer head can improve the efficiency of other crusher equipment by 5% - 15%.

2. Perfect finished granules

The unique roller rubbing process can significantly remove the paint and other contaminants, form high-density pellets and improvethe grade of crushing materials.

3. Stable operation capability

When the safety door is set, after the non-breakable material enters the crushing chamber, the operator can open the safety door and discharge it from the body to avoid damaging the crusher.

4. Intelligent Control System

PLC control system and hydraulic power system can save time and labor in intelligent production and realize stable, automatic and safe operation of the whole production line.

Hydraulic feeding, hammer throwing and ring hammer combined crushing hammer head can improve the efficiency of other crusher equipment by 5% - 15%.

2. Perfect finished granules

The unique roller rubbing process can significantly remove the paint and other contaminants, form high-density pellets and improvethe grade of crushing materials.

3. Stable operation capability

When the safety door is set, after the non-breakable material enters the crushing chamber, the operator can open the safety door and discharge it from the body to avoid damaging the crusher.

4. Intelligent Control System

PLC control system and hydraulic power system can save time and labor in intelligent production and realize stable, automatic and safe operation of the whole production line.

PRODUCT SPECIFICATIONS

|

model

|

size(LxWxH)

|

blade diameter

|

blade quantity

|

weight

|

|

Aite-80

|

2800x1300x1850

|

275

|

72

|

3600

|

|

Aite-100

|

3000x1300x1850

|

275

|

96

|

4000

|

|

Aite-120

|

3300x1900x2200

|

315

|

120

|

6500

|

|

Aite-140

|

3600x2000x2200

|

315

|

144

|

7500

|

|

Aite-160

|

4180x2100x2400

|

350

|

180

|

9000

|

|

Aite-180

|

5400x2700x3500

|

500

|

240

|

20000

|

Successful Project

Hot Searches