- Product Details

- {{item.text}}

Quick Details

-

Min Height:

-

customized

-

Name:

-

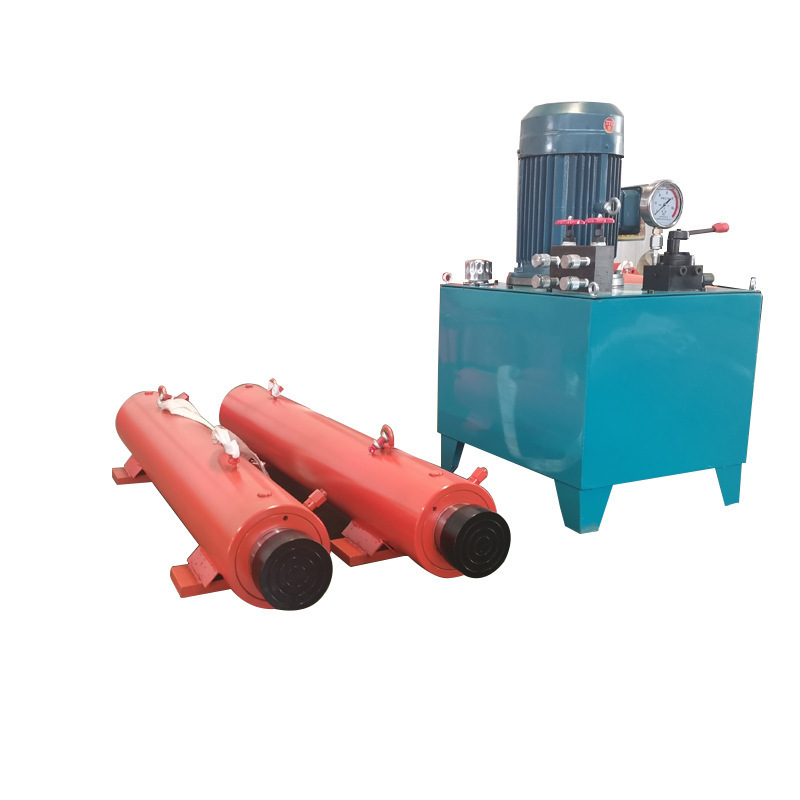

Hydraulic Pipe Jacking Machine

-

Capacity:

-

50-5000Ton

-

Application:

-

Bridge construction, pile pressing, foundation settlement

-

Construction Technology:

-

Free technical guidance

-

Use Area:

-

Engineering Construction

-

Max Torque(kN.m):

-

177~2001 kN.m

-

Speed:

-

3.4~4.4 rpm

-

Powe:

-

22x2~45x8 KW

-

Torque:

-

89kN.m

-

Color:

-

customized

Quick Details

-

Warranty:

-

3 years

-

Max Height:

-

customized

-

Place of Origin:

-

China

-

Min Height:

-

customized

-

Name:

-

Hydraulic Pipe Jacking Machine

-

Capacity:

-

50-5000Ton

-

Application:

-

Bridge construction, pile pressing, foundation settlement

-

Construction Technology:

-

Free technical guidance

-

Use Area:

-

Engineering Construction

-

Max Torque(kN.m):

-

177~2001 kN.m

-

Speed:

-

3.4~4.4 rpm

-

Powe:

-

22x2~45x8 KW

-

Torque:

-

89kN.m

-

Color:

-

customized

Special for construction Pipe jack Hydraulic Pipe Jacking Machine

working principle:

Pipe jacking construction is an underground pipeline construction method developed after shield construction. It does not need to excavate the surface layer, and can cross roads, railways, rivers, ground buildings, underground structures and various underground pipelines.

In the pipe jacking construction, the tool pipe or the roadheader is pushed from the working well through the soil layer until it is received and hoisted by means of the thrust of the main jacking oil cylinder and the relay room between the pipes. At the same time, the pipeline following the tool pipe or the roadheader is buried between the two wells, in order to realize the construction method of laying the underground pipeline without excavation.

Features:

1.High reliability:Hydraulic overload protection system is reliable and safer,and the water proof is good.

2.Great geology adaptability:Revolution can be adjusted without grade and different cutting wheels are designed for different

ground conditions.So it makes great adaptability.

3.High rock breaking efficiency:The special design of large eccentric cone crusher can raise the working efficiency with secondary

crushing which also makes rock pieces easier to discharge.

4.Good construction operability:Jacking speed and slurry flow can be continuously adjusted that makes it easier to achieve a

balance of jacking speed and delivery of slurry flow.

Details:

|

Description |

Unit |

Parameter value |

|

|

Pipe diameter |

ID |

mm |

Φ1000 |

|

OD |

Φ1200 |

||

|

Extend diameter |

mm |

Φ1100 |

|

|

Φ1200 |

|||

|

Outer diameter× length |

mm |

Φ1220×3600 |

|

|

Cutting wheels |

Motor power |

kW |

15×2 |

|

Torque |

kN.m |

89 |

|

|

Revolution |

r/min |

0-2.8-3.9 |

|

|

Roll correction system |

Force per cylinder |

kN |

480 |

|

Cylinder number |

EA |

3 |

|

|

Steering angle |

° |

3 |

|

|

Motor power |

kW |

2.2 |

|

|

slurry line diameter |

mm |

Φ100 |

|

|

Total power |

kW |

47.2 |

|

|

Weight |

kg |

6000 |

|

|

Jacking cylinders |

Thrust |

kN |

1500 |

|

Number |

EA |

2 |

|

|

Stroke |

mm |

1250×2 |

|

|

Charge pump Motor power |

kW |

22 |

|

|

Discharge pump Motor power |

kW |

22 |

|

|

Injection pump Motor power |

kW |

11 |

|