- Product Details

- {{item.text}}

Quick Details

-

Use:

-

Steel plate guilding platform

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

QJ

-

Voltage:

-

380V 50HZ 3Phase

-

Dimension(L*W*H):

-

8m*1m*1.4m

-

Weight:

-

4 tons

-

Material:

-

galvanized/color steel sheet

-

Thickness:

-

0.3-0.6mm

-

Frame:

-

H beam seamless welded

-

Transmission:

-

sprocket and chain

-

Chain:

-

1 inch

-

Forming stations:

-

12-15

-

Wall plate thickness:

-

18mm

-

Shaft:

-

75mm, solid

-

Driving motor power:

-

4kw

-

Roller material:

-

45# forged steel

-

Certification:

-

SGS TUV

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

12-16M/min

-

Use:

-

Steel plate guilding platform

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

QJ

-

Voltage:

-

380V 50HZ 3Phase

-

Dimension(L*W*H):

-

8m*1m*1.4m

-

Weight:

-

4 tons

-

Material:

-

galvanized/color steel sheet

-

Thickness:

-

0.3-0.6mm

-

Frame:

-

H beam seamless welded

-

Transmission:

-

sprocket and chain

-

Chain:

-

1 inch

-

Forming stations:

-

12-15

-

Wall plate thickness:

-

18mm

-

Shaft:

-

75mm, solid

-

Driving motor power:

-

4kw

-

Roller material:

-

45# forged steel

-

Certification:

-

SGS TUV

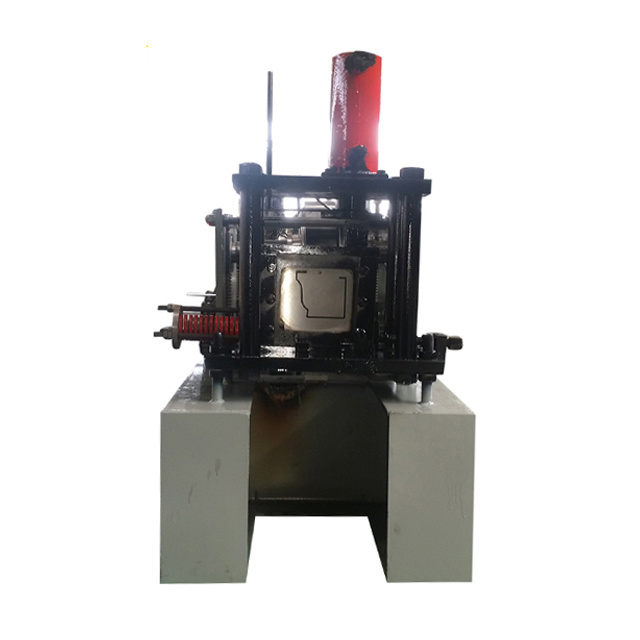

forming machine for square tube downspout forming machine

|

No. |

Rain Gutter Roll Forming Making Machine steel gutter downspout cold roll forming machine |

|

|

1 |

Suitable material |

PPGI/Aluminium sheet/galvanized sheet/various sheet plates |

|

2 |

Thickness of coil sheet |

0.3-0.6mm |

|

3 |

Coil width |

300mm |

|

4 |

Cover width |

125mm |

|

5 |

Material of main frame |

H beam seamless welded |

|

6 |

Diameter of Soild shaft |

mm, high grade 45# steel |

|

7 |

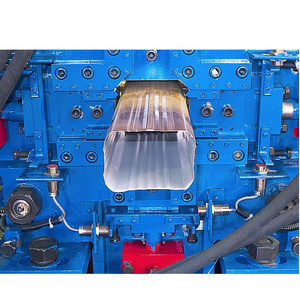

Roller |

Quenched and tempered treatment, hard chrome coated.05-0.07mm |

|

8 |

Thickness of middle plate |

16-18mm |

|

9 |

Forming station |

12-15 stations |

|

10 |

Drive type |

By chain(1.0 inch) link bearing model 6210 |

|

11 |

Power of main motor |

4.0-5.5kw with Cycloidal reducer |

|

12 |

Power of pump station |

4kw |

|

13 |

Forming speed |

About 12-16m/min |

|

14 |

Hydraulic cutting |

Controlled by PLC |

|

15 |

PLC |

DELTA(TAIWAN)/Mitsubishi |

|

16 |

Material of razor blades |

Cr 12, quenching 58-62 ℃ |

|

17 |

Frequency converter |

It has the advantage of slowing down before cutting, to ensure the length accuracy(±1mm, far better than industrial standard ±3mm). |

|

18 |

Switch |

CHNT |

|

19 |

Transducer |

SAJ |

Q 1 . What are the main key points for selecting right machines ?

A 1 : Whole structure,Roller Shaft,Roller Material,Motor&Pump,and Control system. As the new buyer, please kindly know that price not the final point.

Good quality is for long-term business cooperation.

Q 2 . Can you provide OEM service for roll forming machine ?

A 2 : Yes, most of cold roll forming machine need to be customized as detailed request, because raw material , size , production usage, machine speed, then machine specification will be some different.

Q 3 . What ’ s your standard trade terms ?

A2: We can provide the technical offer with FOB,CFR,CIF,Door to Door and so on. Please kindly tell the detailed port name for competitive ocean freight.

Q 4 . How about the quality control ?

A 4 : Our c o mpany adopts 6S system to control every part with passed ISO9001:2000, CE,TUV/BV(.) Certificate.

Q 5 . How about the after-sale service ?

A 5 : We provide 18 months free warranty and free technical support for the whole life of any machine. During warranty period, if parts still broken, we can send the new ones freel y.

Q6. If I am in Beijing ,Shanghai or Guangzhou ,h ow to visit your company?

A6: 1) Beiing South Statioin to Cangzhou West Station ( by fast train 1 hour).

2) Shanghai Hongqiao to Cangzhou West (4.5 hours)

3) Guangzhou Airport to Tianjin ,then Tianjin to Cangzhou West

When you arrive our station, we will arrange to pick up you there!