- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

vmax

-

Weight (KG):

-

6.5 KG

-

Product name:

-

screen protector cutting film cut machine

-

Size:

-

500*200*170mm

-

Weight:

-

7 KG

-

High Clear TPU Film:

-

108*180mm;120x180mm

-

Matte TPU Film:

-

108*180mm; 120x180mm

-

Cutting needles:

-

200 times/neddle should be changed a new one after 200 times cutting

-

Thickness:

-

0.15mm

-

Type:

-

Clear / matte/ blue ray

-

Transparency:

-

99% HD

-

Function:

-

Cutting different mobile phone screen protector

Quick Details

-

Laser Type:

-

SEMICONDUCTOR

-

Cutting Speed:

-

200 times/neddle

-

Cutting Thickness:

-

0.15mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

vmax

-

Weight (KG):

-

6.5 KG

-

Product name:

-

screen protector cutting film cut machine

-

Size:

-

500*200*170mm

-

Weight:

-

7 KG

-

High Clear TPU Film:

-

108*180mm;120x180mm

-

Matte TPU Film:

-

108*180mm; 120x180mm

-

Cutting needles:

-

200 times/neddle should be changed a new one after 200 times cutting

-

Thickness:

-

0.15mm

-

Type:

-

Clear / matte/ blue ray

-

Transparency:

-

99% HD

-

Function:

-

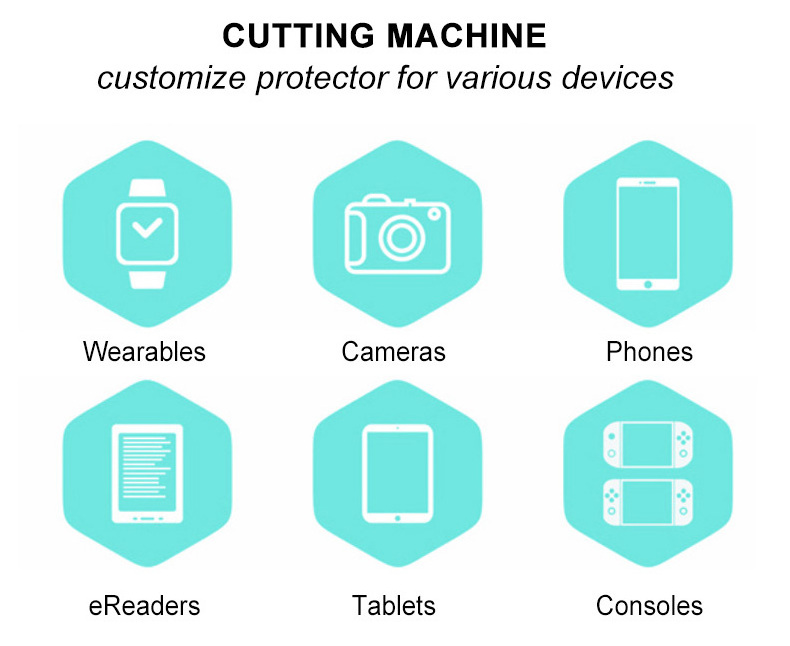

Cutting different mobile phone screen protector

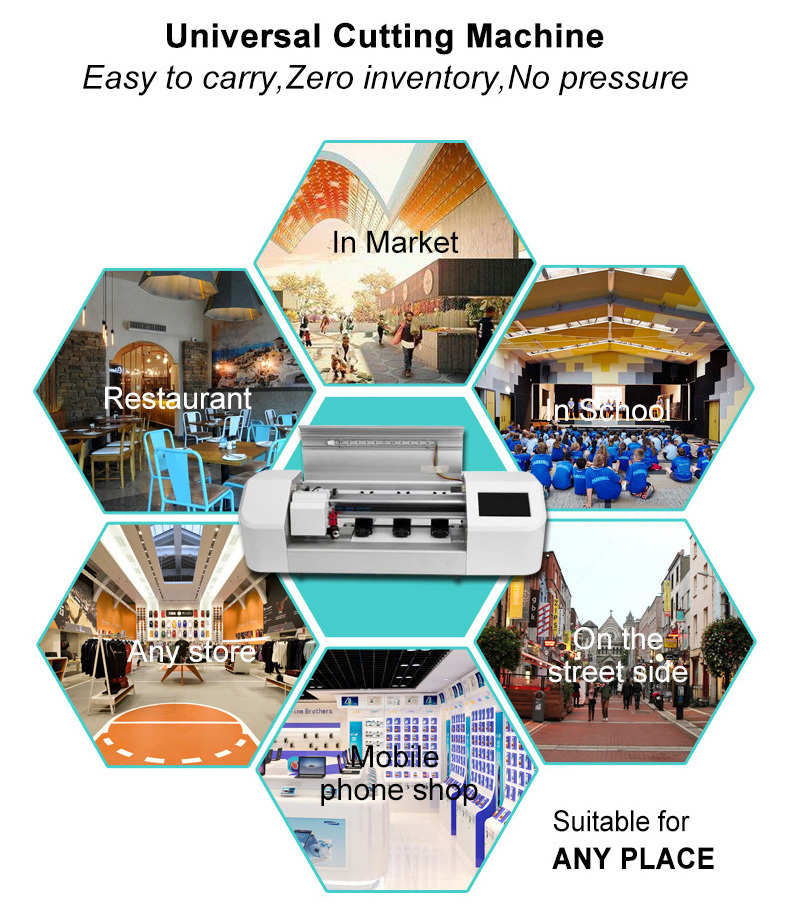

Customized Fully automatic Mobile phone screen protector cutting film cut machine

| S310 Screen Protector Cutting Machine Specifications | |

| Machine Size | 520*170*165mm |

| Function | Cutting different mobile phone screen protector |

| Machine Weight | 6.5kg |

| Machine Input voltage | 110V-240V wide-band voltage. |

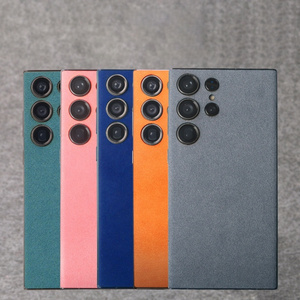

| Cutting Material | Nano, Carbon firber, Silk fabric material screen protetcor,Clear, Matte, Anti Blue light front protector material |

Machine illustrationo and function introduction of each part:

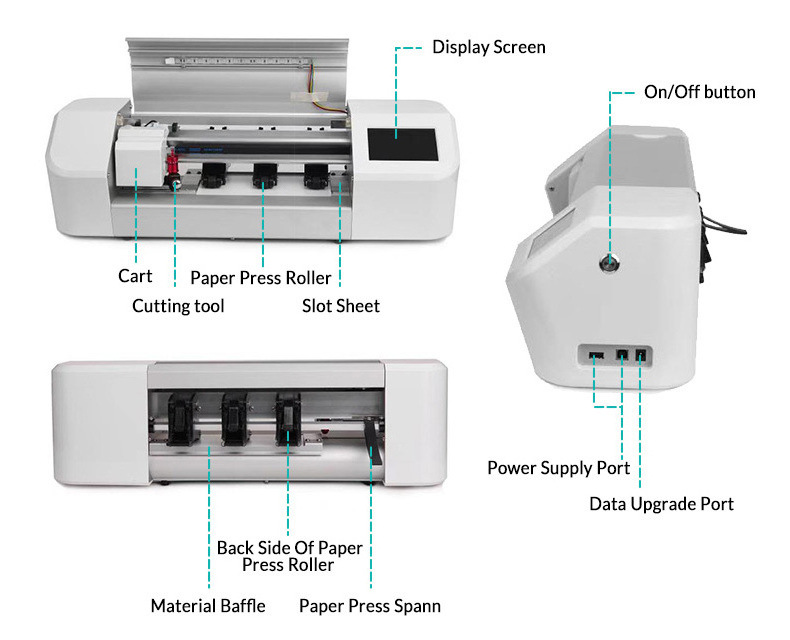

1. LCD display screen(Function: Display machine LOGO, there is setting machine parameters key)

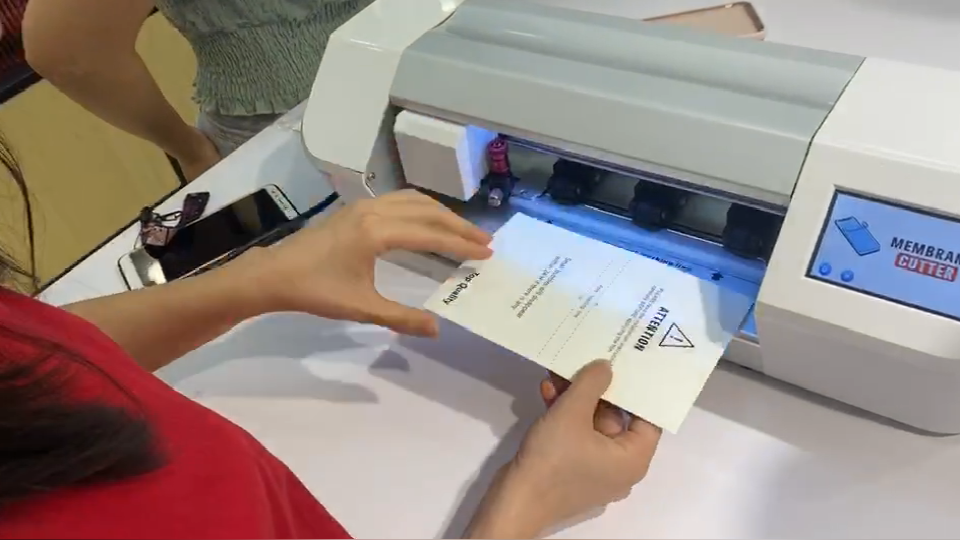

2. Slot sheet (there are two slot sheets on both sides for position after put in)

3. Paper press wheel (Press cutting material forward and backward movement)

4. Knife holder (for cutting the material)

5. Cart(For left & right cutting and 1oading & unloading paper/ blades)

6. Paper press spanner (Pull up and down to control the press wheel to press and loosen the material)

7. Back side of paper press wheel

8. Material baffle (Cutting material is pushed directly to the baffle for position.)

10. Power supply port (Interface to connect the machine power adapter)

11. Start switch (the switch button for starting the machine. The blue light will turn on, and the power will be turned off only after 3 seconds of long press to start the switch.)

12. Data upgrade port(USB and U-disk port for upgrading versions ofmachine through computer)

13.Power cable socket(It corresponds to the machine power supply port in position 10 directly, plug to power on the machine.)

14.Power supply adapter( input 110-220V wideband voltage Input 24V-2A)

15.Power supply cable(Connect to power)

Contact us for detailed instructions

Product Details:

Contact Us Get The Product Test Report or video