- Product Details

- {{item.text}}

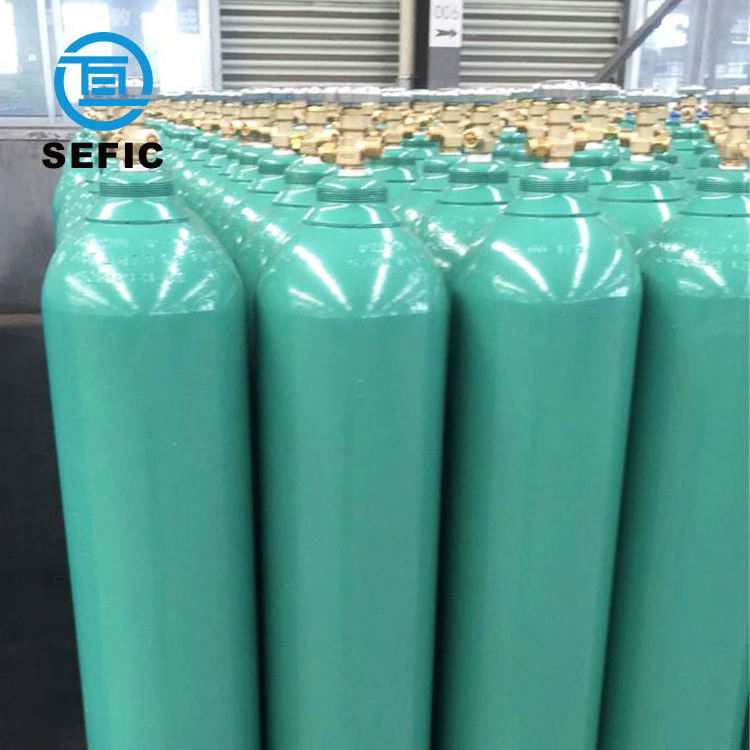

Quick Details

-

Model Number:

-

40L/150Bar

-

Brand Name:

-

SEFIC

-

Type:

-

40L/150Bar Seamless Steel Gas Cylinder

-

Outside Diameter:

-

219mm

-

Height:

-

1315mm

-

Weight:

-

48kg

-

Working Pressure:

-

150Bar

-

Water Capacity:

-

40L

-

Wall Thickness:

-

5.7mm

-

Standard:

-

IS09809-3

-

Filling Gas:

-

O2 N2 Ar=6m³ LCO2=24KG

-

Test Pressure:

-

250bar

Quick Details

-

Material:

-

Steel

-

Use:

-

Industrial Gas

-

Place of Origin:

-

Shanghai, China

-

Model Number:

-

40L/150Bar

-

Brand Name:

-

SEFIC

-

Type:

-

40L/150Bar Seamless Steel Gas Cylinder

-

Outside Diameter:

-

219mm

-

Height:

-

1315mm

-

Weight:

-

48kg

-

Working Pressure:

-

150Bar

-

Water Capacity:

-

40L

-

Wall Thickness:

-

5.7mm

-

Standard:

-

IS09809-3

-

Filling Gas:

-

O2 N2 Ar=6m³ LCO2=24KG

-

Test Pressure:

-

250bar

Products Description

|

Standard

|

Outside

diameter(mm)

|

Water capacity

(L)

|

Height(mm)

|

Weight(kg)

|

Certiication

|

Servic pressure

(MPa)

|

Test pressure

(MPa)

|

Wall Thickness

(mm)

|

Material

|

|

ISO9809-1

|

159

|

8-15

|

553-955

|

12.1-19.8

|

TPED

|

20

|

30

|

3.5

|

34CrMo4

|

|

ISO9809-1

|

203

|

13.4-42.0

|

580-1580

|

20.5-49.0

|

TPED

|

20

|

30

|

5.4

|

34CrMo4

|

|

ISO9809-3

|

219

|

19-64.5

|

670-2040

|

25-67.5

|

TPED

|

15

|

25

|

5.3

|

37Mn

|

|

ISO9809-3

|

219

|

20-50

|

715-1615

|

28-60

|

TPED

|

15

|

25

|

5.7

|

37Mn

|

|

ISO9809-1

|

229

|

20-55

|

660-1608

|

28.9-61.8

|

TPED

|

20

|

30

|

5.7

|

34CrMo4

|

|

ISO9809-1

|

229

|

20-55

|

680-1660

|

36.0-75.0

|

TPED

|

30

|

45

|

6.95

|

34CrMo4

|

|

ISO9809-1

|

229

|

20-70

|

715-2160

|

44-120

|

TPED

|

30

|

45

|

8.5

|

34CrMo4

|

|

ISO9809-1

|

232

|

38-52

|

1110-1475

|

41-54

|

TPED

|

20

|

30

|

5.4

|

34CrMo4

|

|

ISO9809-1

|

232

|

38-74.9

|

1120-2152.5

|

43.4-80.9

|

TPED

|

23

|

34.5

|

5.8

|

34CrMo4

|

|

ISO9809-1

|

267

|

50-90

|

1120-1920

|

53-85

|

TPED

|

16.66

|

25

|

5.9

|

37Mn

|

|

ISO9809-1

|

267

|

50-90

|

1120-1920

|

55-91

|

TPED

|

20

|

30

|

6.2

|

34CrMo4

|

|

ISO9809-1

|

356

|

50-200

|

710-2360

|

46-174

|

TPED

|

20

|

30

|

7.5

|

34CrMo4

|

Product packaging

Product Process

1.Raw material

2.Cutting

3.Bottom forming

4.Bottom concave

5.Milling bottom

6.Bottle mouth forming

7.Heat treatment

8.Bottle thread processing

9.Installation neck ring

10.Shoulder stamp

11.Water pressure test

12.External polishing

13.Inner polishing

14.Spray paint

15.Valve installation

16.Airtight test

Hot Searches