- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.1

-

Voltage:

-

110v 220V 380V

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

KEFAI

-

Dimension(L*W*H):

-

120*65*45cm

-

Weight:

-

110 KG

-

Product name:

-

KEFAI desktop filling line

-

Material::

-

stainless steel

-

working head:

-

4 heads

-

Speed:

-

40-60 bottles/min

-

Filling material:

-

low viscosity liquid

-

Filling range:

-

5-500ml

-

Air Source:

-

0.4-0.7Mpa

Quick Details

-

Machinery Capacity:

-

12000BPH, 500BPH, 1000BPH

-

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

Water

-

Filling Accuracy:

-

±0.1

-

Voltage:

-

110v 220V 380V

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

KEFAI

-

Dimension(L*W*H):

-

120*65*45cm

-

Weight:

-

110 KG

-

Product name:

-

KEFAI desktop filling line

-

Material::

-

stainless steel

-

working head:

-

4 heads

-

Speed:

-

40-60 bottles/min

-

Filling material:

-

low viscosity liquid

-

Filling range:

-

5-500ml

-

Air Source:

-

0.4-0.7Mpa

For faster respond and recommend the most suitable machine for you, Please leave your detailed demands:

1. Send us a picture to show your bottle sample

2. Your filling material

3. The filling capacity of each bottle you need.

4. Your production speed requirement.

We can customize the suitable one for you according to your requirement.

Why choose us

1. 15+ years factory

2. Professional R&D Team

3. Customization service

4. 100% QC inspection before shipment

6. Certificate By CE & SGS

7. No third party, from the factory and the buyer to sell one to one

8. Good after-sales experience, provide videos of installation, online support and engineer overseas services.

9. At least one year warranty.

Product Description

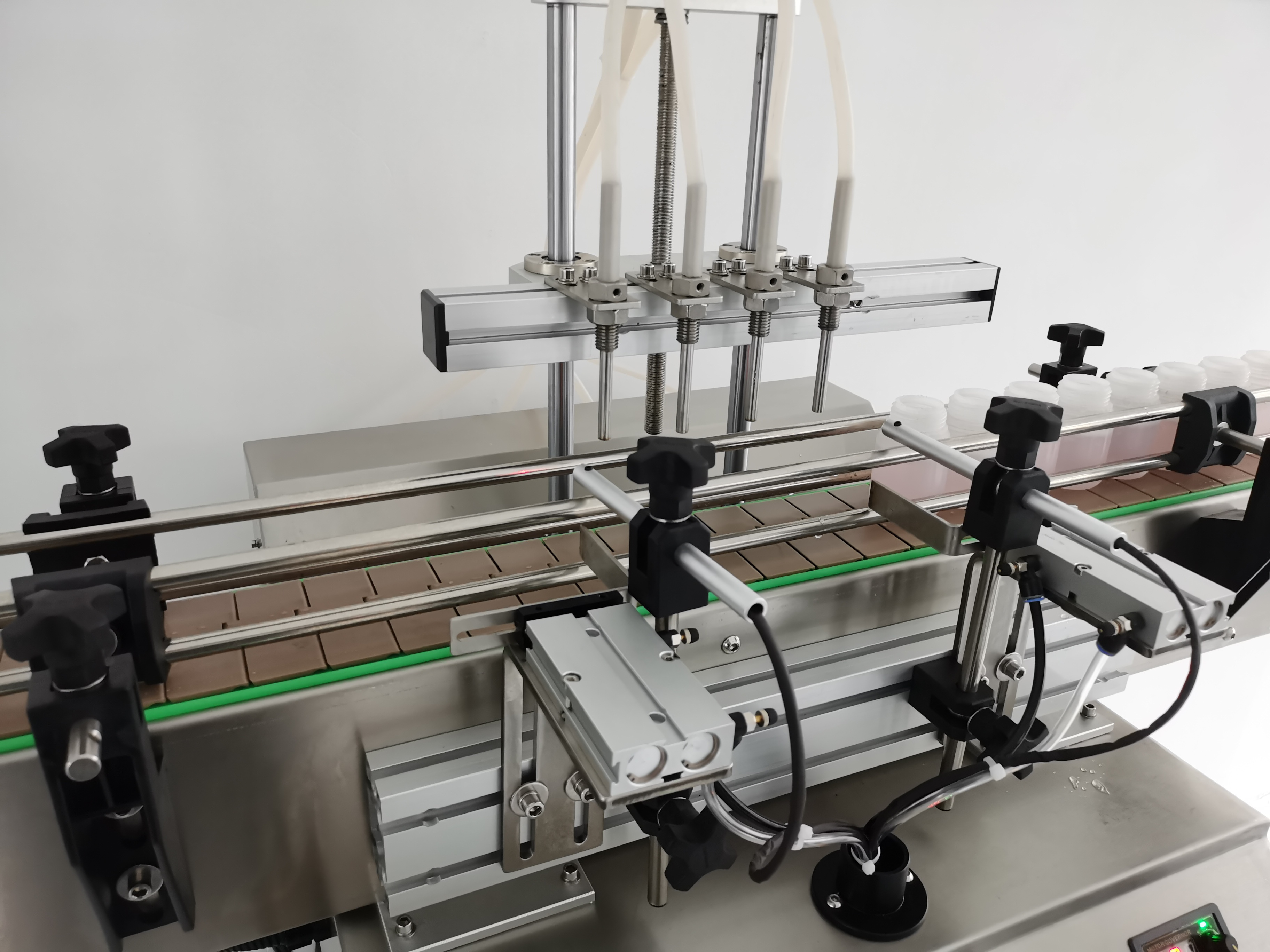

Automatic Four-head Desktop Magnetic Pump Water Liquid Filling Line

Introduction

This desktop filling machine is equipped with chain conveyor belt,compared with the leather conveyor belt,this one is with larger capacity,this makes it suitable for filling larger volume and transport them faster and more smooth.The magnetic pump filling machine is high precision that it can be used to fill essential oil,solution,eye drops,inks,perfume etc.

Adopts corrosion-resistant stainless steel micro self-priming magnetic pump of special materials. The working time and intermittent time of the pump are controlled by microcomputer to realize quantitative automatic filling and automatic setting of tube loading time. simple structure, convenient operation, lengthening the material nozzle and moving the leather tube arbitrarily,can meet the unlimited capacity of more than 5g. Reliable and durable filling equipment. Can be customized to extend the tube mobile filling, convenient and practical.

4 head magnetic pump filling machine can not only be used alone, but also can be combined with capping machine equipment to form the four head magnetic pump filling and capping production line. In addition, according to the actual production needs of customers, the corresponding equipment and functions of labeling machine, inkjet printer, sealing machine and packer can be added, which can improve the production line.

liquid filler honey gear pump

Features

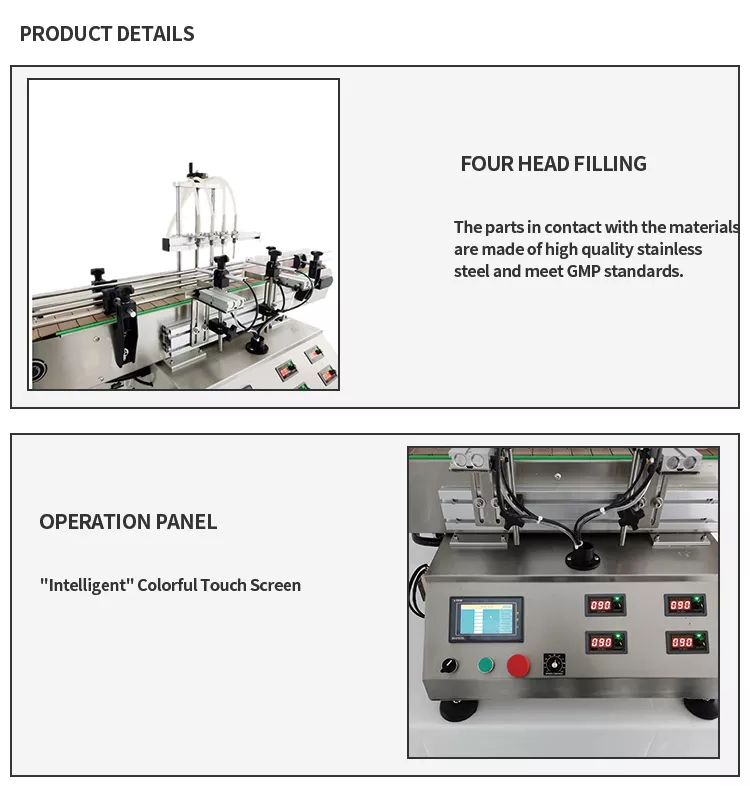

& No Bottle or Lack of Bottle, No Filling System

& Photoelectric Sensor, Mechatronics Filling Adjustment System

& Photoelectric Sensor, Material Level Control Feeding System

& Control System: PLC/Electronic-Pneumatic Controlled

& Operation Panel: "Intelligent" Colorful Touch Screen

& Filling Accuracy:±0.5%

& Capacity Adjustment: Can adjust the required filling capacity, filling speed and so on on the touch screen.

& Container transport: Stainless steel frame and engineering plastic plate chain variable speed conveyor, with photoelectric sensor.

& Photoelectric Sensor, Mechatronics Filling Adjustment System

& Photoelectric Sensor, Material Level Control Feeding System

& Control System: PLC/Electronic-Pneumatic Controlled

& Operation Panel: "Intelligent" Colorful Touch Screen

& Filling Accuracy:±0.5%

& Capacity Adjustment: Can adjust the required filling capacity, filling speed and so on on the touch screen.

& Container transport: Stainless steel frame and engineering plastic plate chain variable speed conveyor, with photoelectric sensor.

Application

This machine is widely used in food, medicine, chemical, daily chemical and other industries, such as honey, tomato sauce, rice wine, rice pudding, seafood sauce, chili sauce, oil, lubricants, detergent, laundry detergent and other thick materials. The parts in contact with the materials are made of high quality stainless steel and meet GMP standards.

Specification

Following specification is one of the model, please kindly send us your detailed requirements, we will choose the suitable model for you.

|

Model

|

KF01-L 2000-4H

|

|

Filling heads

|

Four heads

|

|

Power

|

380/220V,50HZ,500W

|

|

Filling range

|

5-2000ml (can be customized)

|

|

Filling speed

|

1600-1800 bottles/Hour

|

|

Filling accuracy

|

±0.5-1%

|

|

Dimension of machine

|

(L)1350*(W)850*(H)1350mm; 125Kg

|

Details of machine

Desktop Capping Machine

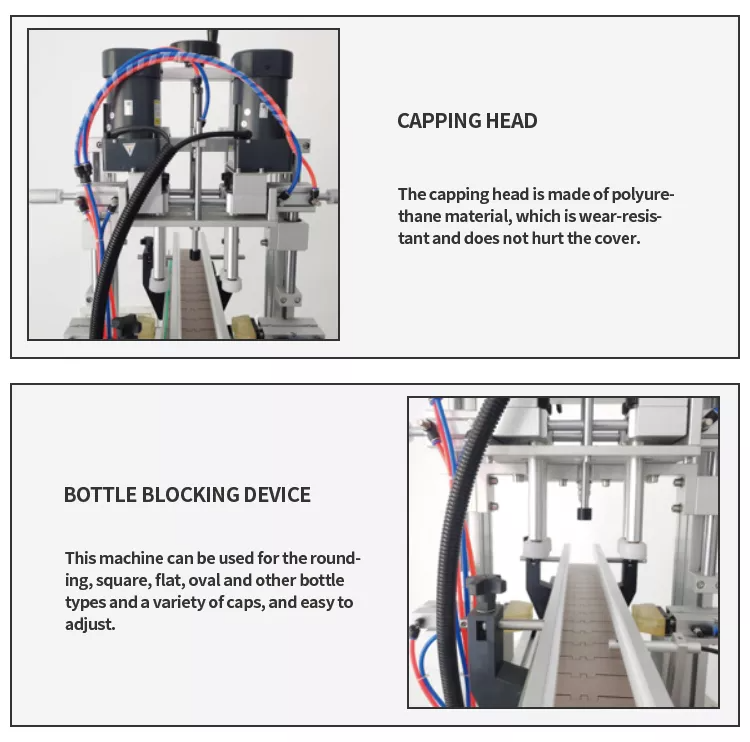

This machine is used for automatic capping of plastic bottles and glass bottles in cosmetics,food and beverage, pesticide and fertilizer, chemical industry, suitable for various shapes of bottle caps, high production efficiency.

Features

1, The working height can be adjusted by the rotary knob,suitable bottle height is 50-270mm. If the customer has a taller bottle. We can customize the machine for free and provide suitable customized programs for free.

2, Designed for various shapes of bottle caps, like smoke oil bottles, spray bottles, beverage bottle caps. It will press the bottle caps and tight it automatically. Improve working efficiency greatly.

3, This machine is equipped with electric eyes, can prevent from missing bottles, reduce the working error, the sensitivity of the electric eye can be adjusted by the black machine part during working.

4, With conveyor,this machine can transfer bottles automatically,save labor ,reduce the production process and improve the working accuracy.

5, Equipped with powerful motor,the main motors and the conveyor motor are separately, ensure that the machine can work stably and safely.

6, The barometer can be used to watch the air pressure in real time.This machine should work with air compressor ,customers need to buy it separately.If you need it,please contact us.

2, Designed for various shapes of bottle caps, like smoke oil bottles, spray bottles, beverage bottle caps. It will press the bottle caps and tight it automatically. Improve working efficiency greatly.

3, This machine is equipped with electric eyes, can prevent from missing bottles, reduce the working error, the sensitivity of the electric eye can be adjusted by the black machine part during working.

4, With conveyor,this machine can transfer bottles automatically,save labor ,reduce the production process and improve the working accuracy.

5, Equipped with powerful motor,the main motors and the conveyor motor are separately, ensure that the machine can work stably and safely.

6, The barometer can be used to watch the air pressure in real time.This machine should work with air compressor ,customers need to buy it separately.If you need it,please contact us.

|

Model

|

KF05-CP

|

|

Bottle height

|

50-270mm (Can be customized)

|

|

Bottle Caps Diameter

|

18-70mm (Can be customized)

|

|

Working speed

|

20-40 bottles/minute(depending on bottle and caps)

|

|

Working voltage

|

AC220V/110V 50-60HZ

|

|

Working pressure

|

0.4-0.6 MPa

|

|

Machine size

|

About 1300*680*1000mm

|

|

Package size

|

About 1400*750*1150mm

|

|

Package weight

|

About 110 kg

|

|

Conveyor length

|

1300mm

|

Desktop Labeling Machine

Description

Designed for label stickers on regular bottles(includes hexagon bottles, round bottle, square bottles). It is widely used in food, daily chemical and cosmetics industries.

Features

1, The electric eye can be used to passing by bottles and send signal back to system to control the machine label stickers.With this, the machine can work automatically. The sensitivity of the electric eye can be adjusted by adjusting components, this can improves labeling accuracy.

2, The bottle will be pushed and rotated to label stickers.This kind of labeling method is suitable for regular bottles includes round bottles, square bottles and hexagon bottles.

3, The chain conveyor belt is with large weight capacity, it can ensures that bottles will be transported stably and fast. It can be connected to automatic filling and capping machine to realize automated production.

4, The labeling heads can be adjusted in different directions, this can ensures the self-adhesive stickers can be labeled better,improves labeling accuracy.

5, Drawer type design makes it more convenient to adjust and maintain the machine during working,this extends the service life of the machine.

Designed for label stickers on regular bottles(includes hexagon bottles, round bottle, square bottles). It is widely used in food, daily chemical and cosmetics industries.

Features

1, The electric eye can be used to passing by bottles and send signal back to system to control the machine label stickers.With this, the machine can work automatically. The sensitivity of the electric eye can be adjusted by adjusting components, this can improves labeling accuracy.

2, The bottle will be pushed and rotated to label stickers.This kind of labeling method is suitable for regular bottles includes round bottles, square bottles and hexagon bottles.

3, The chain conveyor belt is with large weight capacity, it can ensures that bottles will be transported stably and fast. It can be connected to automatic filling and capping machine to realize automated production.

4, The labeling heads can be adjusted in different directions, this can ensures the self-adhesive stickers can be labeled better,improves labeling accuracy.

5, Drawer type design makes it more convenient to adjust and maintain the machine during working,this extends the service life of the machine.

|

Machine model

|

KF06-AL

|

|

Machine voltage

|

110/220V 50-60HZ

|

|

Machine power

|

About 1000W

|

|

Labeling accuracy

|

±1mm (excluding bottle and positioning error)

|

|

Working speed

|

30-50 bottles/min

|

|

Suitable bottles size

|

H≤150mm, φ≤100 (can be customized)

|

|

Suitable label size

|

H≤150mm (can be customized)

|

|

Machine size

|

About 1300*800*800mm

|

|

Machine weight

|

About 104kg

|

If You Want To Know More About The Machine Details,

Please Send An Inquiry To Get It

Packing & Delivery

All the products before delivery should be tested by assemble and debugging engineer, wiped up and cleaned, the wrapped by stretch film to protect it from moist. The precision part needs flexible package. In addition, without standard tools, manual and other documents, and allow ex-factory confirmation sheet, the machine cannot leave factory. All the products will be packed in wooden case. The exported products use plywood case to pack. The foot margin of equipment fixed tightly to make the machine can experience loading and uploading, the upward mark will be posted on the wooden case.

Hot Searches