According to different Materials Charactors , suggest the suitable system

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

0.1%

-

Voltage:

-

220V 50HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ZT-PACK

-

Dimension(L*W*H):

-

2200* 1300* 2350mm

-

Weight:

-

1800 KG

-

Processing Types:

-

net weight load cell

-

Bottle type:

-

Drum Jerry Can Gallons

-

Suitable for:

-

Oil / chemical

-

Advantage:

-

Accurate Filling

-

Control:

-

PLC +HMI + LOAD CELL

-

Capacity:

-

200-600 drums/hour base on 20L

-

Processing:

-

Filling+weighing+capping

-

Machine material:

-

Food Grade SS304 / SS316

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Online support

Quick Details

-

Machinery Capacity:

-

400BPH, 500BPH, 200BPH, 200-600Drums/hour on 20L

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

Oil, Other, chemical, Liquid

-

Filling Accuracy:

-

0.1%

-

Voltage:

-

220V 50HZ

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ZT-PACK

-

Dimension(L*W*H):

-

2200* 1300* 2350mm

-

Weight:

-

1800 KG

-

Processing Types:

-

net weight load cell

-

Bottle type:

-

Drum Jerry Can Gallons

-

Suitable for:

-

Oil / chemical

-

Advantage:

-

Accurate Filling

-

Control:

-

PLC +HMI + LOAD CELL

-

Capacity:

-

200-600 drums/hour base on 20L

-

Processing:

-

Filling+weighing+capping

-

Machine material:

-

Food Grade SS304 / SS316

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Online support

Auto Jerry can Engine Oil Filler sunflower cooking oils Packing 20 liters kg load cell Flow meter filling machine

Edible oil

(Cooking Oil , sunflower oil , peanut oil , seasame oil ..., etc.);

Automatic packaging of Oil liquids.

(Cooking Oil , sunflower oil , peanut oil , seasame oil ..., etc.);

Automatic packaging of Oil liquids.

Lubricant Oil

:

Car Oil / Motor Oil / coolant liquid / engine oil / Lubricanting Oil kinds Products

Agrohchemicals :

Pesticide , fertilizer ,suspending agents, liquids, emulsifiable concentrates and water-soluble fertilizers, Acaricide,Fungicide,herbicide, EC ,SC , SL etc.);

Filling Range : 4L-30L

Filling Range : 4L-30L

5kg -30kg

Filling System can be choosen : Net Weight Load Cell

Filling System can be choosen : Net Weight Load Cell

Flow Meter

Speed can be choosen : from 200BPH-600BPH (basic on 20L )

Filling Line Machines included (can be choosen):

Speed can be choosen : from 200BPH-600BPH (basic on 20L )

Filling Line Machines included (can be choosen):

Filling Machine--Capping Machine -- Induction sealing machine -- Aluminum Foil detector and rejector --Labeling Machine --Date Printer -- Palletilizer

|

Model

|

ZCJ-4

|

ZCJ-6

|

|

|

Dimension

|

3000x1700x2300mm

|

3600x1700x2300mm

|

|

|

Filling head

|

4

|

6

|

|

|

Capacity(10L)

|

300 B/H

|

350 B/H

|

|

|

Capacity(20L)

|

250 B/H

|

300 B/H

|

|

|

Power

|

2KW

|

3KW

|

|

|

Suitable bottle

|

length:160-360mm width:100-300mm height:250-500mm

|

|

|

|

Barrel neck diameter

|

≥Φ40mm

|

|

|

|

Filling error

|

≤±0.5%F.S

|

|

|

|

Filling range

|

10KG-30KG

|

|

|

|

Air pressure

|

0.6Mpa—0.8Mpa

|

|

|

|

Power supply

|

220V;50HZ/60HZ

|

|

|

Suitable For Drums Filling Packing Line :

Flow Meter & Net weight Load cell system can be choosen

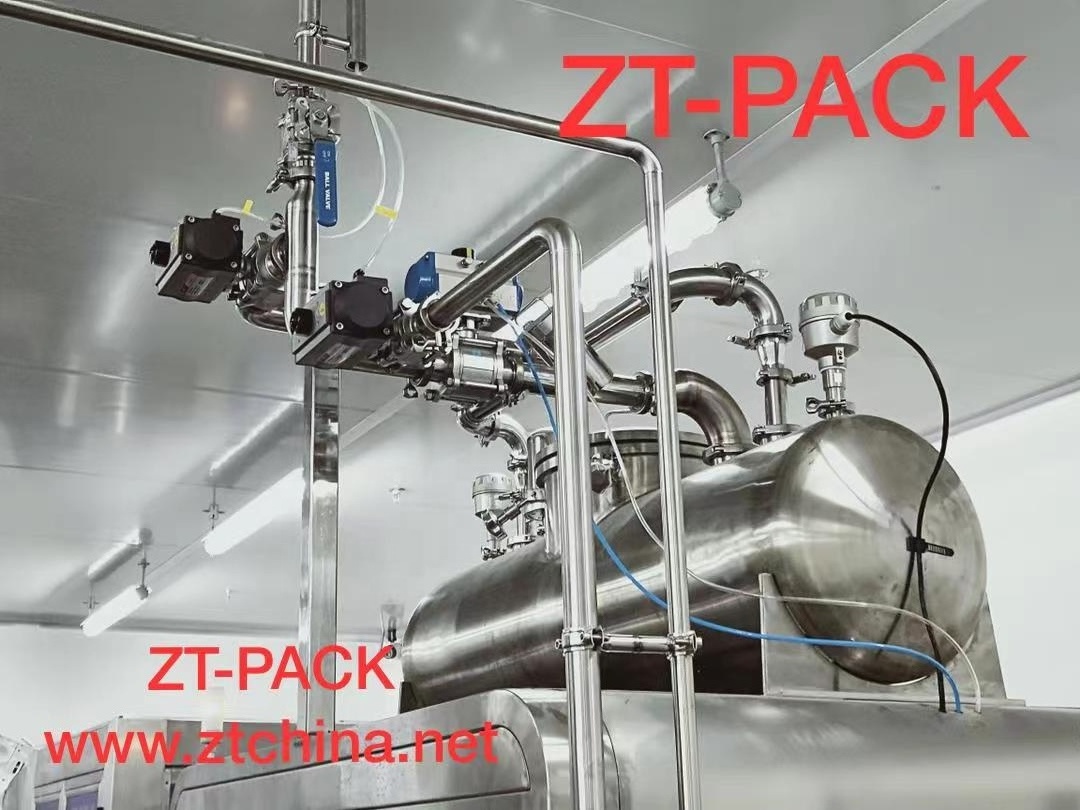

Machine Description:

Net weigh fillers are in ideal solution for ensuring each container you fill has the same amount of product in it. They are the best for liquids filled in bulk quantities, such as 5-gallon oil , or products that have a very high value and thus need to be weighed correctly to avoid losing profit.

This is weigh type filling machine for filling 5-30 KG Liquid .

Net weigh fillers are in ideal solution for ensuring each container you fill has the same amount of product in it. They are the best for liquids filled in bulk quantities, such as 5-gallon oil , or products that have a very high value and thus need to be weighed correctly to avoid losing profit.

This is weigh type filling machine for filling 5-30 KG Liquid .

Gravity filling system with weight scale under filling nozzle to assure filling accuracy.

As well as pressure tank be used to make sure the capacity speed faster.

Linear type machine, can be made with 4/6 filling nozzle for different filling capacity.

It is ideal for filling big volume product like edible oil, wine, lubrication, liquid fertilizer, chemicals etc.

Net weight filler is best suited for liquids to be filled in bulk quantities e.g. 5 gallon pails, etc. or smaller quantity

products that have a very high manufactured value. Oftentimes there are products that must be sold by weight for commercial reasons and therefore this filling machine is the only choice. Examples of this type of filler for bulk products include cleaning chemicals, enzyme solutions, oils and other medium value products. High value products filled by these machines include specialty adhesives and paints, precious metals dissolved in acids, and other expensive specialty chemicals.

The operation of this type of net weight drum filling machine is simple. The product bulk supply is pumped into a holding tank above a pneumatically operated valve. Cleaned containers are conveyed to the filling machine through an SS slat conveyor, positioned on individual load cell platform and tared. the valves open and real time net weight information is monitored until the

target weight is achieved. The valve simply shuts when the target weight is achieved. Accuracy of fills is accomplished by various “bulk and dribble” methods in the filling process so that overfills are avoided.

The advantage of this bucket filling machine over others is that it is sometimes the only practical (and legal) type of filling for a limited range of applications and for large volume fills. It is also very accurate and effectively provides its own quality control assuming the scale is functioning properly. The disadvantage of this type of filling machine is that it is very expensive

per filling head. For these reasons, the use of this filling technology is limited to the examples outlined above.

As well as pressure tank be used to make sure the capacity speed faster.

Linear type machine, can be made with 4/6 filling nozzle for different filling capacity.

It is ideal for filling big volume product like edible oil, wine, lubrication, liquid fertilizer, chemicals etc.

Net weight filler is best suited for liquids to be filled in bulk quantities e.g. 5 gallon pails, etc. or smaller quantity

products that have a very high manufactured value. Oftentimes there are products that must be sold by weight for commercial reasons and therefore this filling machine is the only choice. Examples of this type of filler for bulk products include cleaning chemicals, enzyme solutions, oils and other medium value products. High value products filled by these machines include specialty adhesives and paints, precious metals dissolved in acids, and other expensive specialty chemicals.

The operation of this type of net weight drum filling machine is simple. The product bulk supply is pumped into a holding tank above a pneumatically operated valve. Cleaned containers are conveyed to the filling machine through an SS slat conveyor, positioned on individual load cell platform and tared. the valves open and real time net weight information is monitored until the

target weight is achieved. The valve simply shuts when the target weight is achieved. Accuracy of fills is accomplished by various “bulk and dribble” methods in the filling process so that overfills are avoided.

The advantage of this bucket filling machine over others is that it is sometimes the only practical (and legal) type of filling for a limited range of applications and for large volume fills. It is also very accurate and effectively provides its own quality control assuming the scale is functioning properly. The disadvantage of this type of filling machine is that it is very expensive

per filling head. For these reasons, the use of this filling technology is limited to the examples outlined above.

Zhongtai Packing Machinery Company develops high quality packaging and botting pro-duction lines. From flling to capping to labeling to storing in cartons for shipping, ZT-Pack supplies you with everything you need to get your product into the hands of customers. Our production lines are used for packaging seasonings, sauces, condiments, syrups, and other foods; wine,and other beverages; cosmetic and beauty care products such as lotions, creams, and shampoos; pesti-cides and other agrochemicals;and oils and gases. We help customers from over 30 countries around the world to package their products.

Since our beginnings, we've designed our packaging and bottling equipment to meet the needs of our customers. Our filling machines,capping machines, labeling machines, and carton sealing machines can fll bottles and pouches of vanying specifications with high and low viscous liquid and powdered or granular material. We've passed ISO9001:2008 quality management system certification and CE cer-tification, and we're one of the top ten bottle flling machine suppliers in China. Many of our products have received invention and utility model patents.

Factory with 13,000 m2

Technology Team more than 10 persons

Service Team more than 10 personsstaffs 80 person around

Our growing company has the advantages of large modern manufacturing facilities and a talented team of 20 senior technical staff.We research and develop new products using pneumatic control and photo electric transduction that increase our products' speed,precision, and life span.

At ZT-Pack, we value collaboration and innovation, working together and with our customers to devel-op better packaging solutions that keep products fresh and hold up in transit. With quality management and production processes, our packaging machines meet

industry standards and satisfy those who use them. Whatever your product, we can package it. Contact ZT-Pack today.

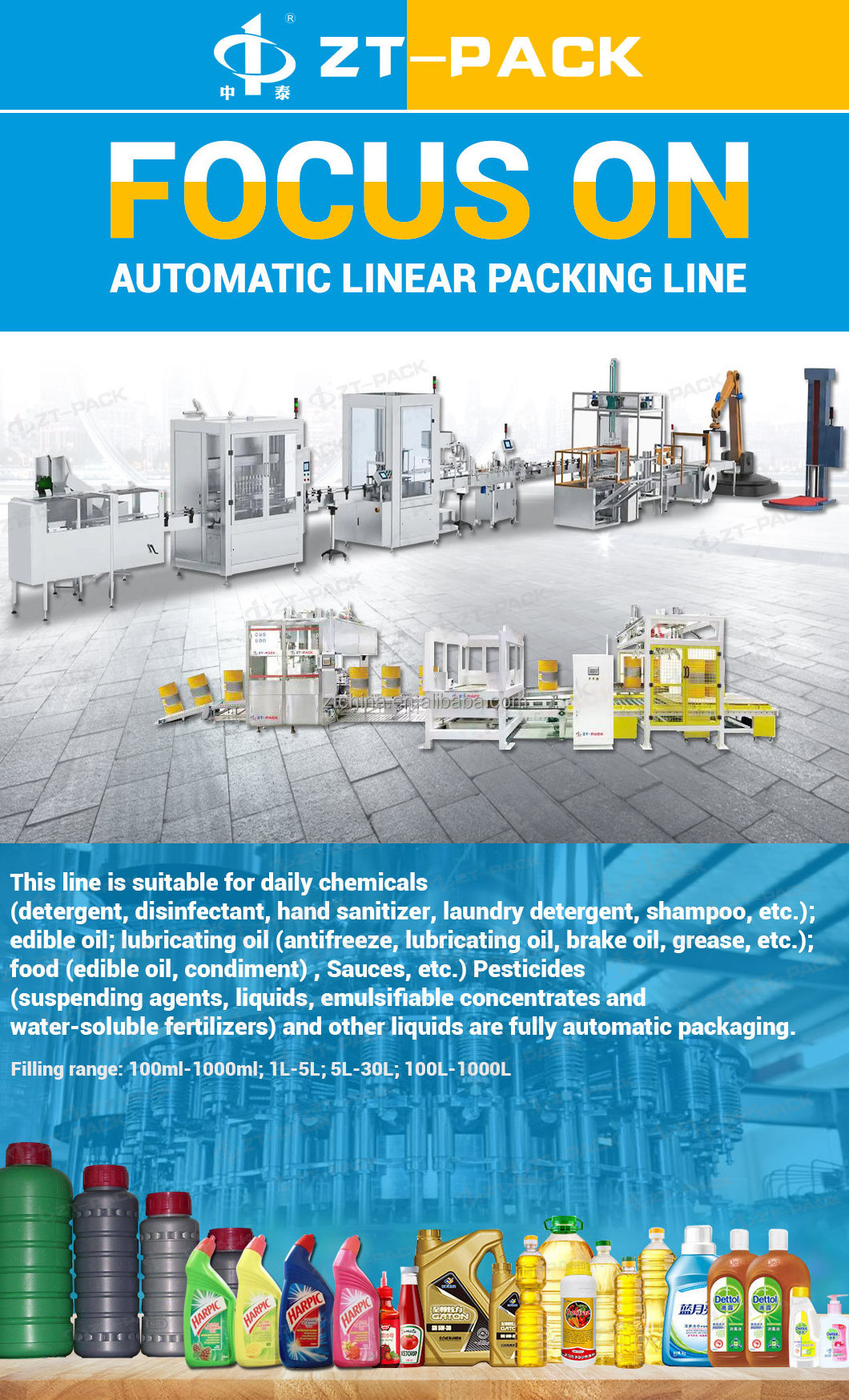

Focus on the bottle production packing machines the full automatic line

Mixer tanks --bottle unscramble -- filling machine --capping machine --labeling machine --carton packing machine –palletilizer

Do for the Bottle /gallons Drum Filling machine production packing line

for agrochemicals , oil , food , lubricant oil ,Home care Cleaning, house holding products , personal care products ; Painting packing

for bottles sizes :

Since our beginnings, we've designed our packaging and bottling equipment to meet the needs of our customers. Our filling machines,capping machines, labeling machines, and carton sealing machines can fll bottles and pouches of vanying specifications with high and low viscous liquid and powdered or granular material. We've passed ISO9001:2008 quality management system certification and CE cer-tification, and we're one of the top ten bottle flling machine suppliers in China. Many of our products have received invention and utility model patents.

Factory with 13,000 m2

Technology Team more than 10 persons

Service Team more than 10 personsstaffs 80 person around

Our growing company has the advantages of large modern manufacturing facilities and a talented team of 20 senior technical staff.We research and develop new products using pneumatic control and photo electric transduction that increase our products' speed,precision, and life span.

At ZT-Pack, we value collaboration and innovation, working together and with our customers to devel-op better packaging solutions that keep products fresh and hold up in transit. With quality management and production processes, our packaging machines meet

industry standards and satisfy those who use them. Whatever your product, we can package it. Contact ZT-Pack today.

Focus on the bottle production packing machines the full automatic line

Mixer tanks --bottle unscramble -- filling machine --capping machine --labeling machine --carton packing machine –palletilizer

Do for the Bottle /gallons Drum Filling machine production packing line

for agrochemicals , oil , food , lubricant oil ,Home care Cleaning, house holding products , personal care products ; Painting packing

for bottles sizes :

50ml -1000ml

1L-5L

5L -30L

220L

1ton

Q:Are you a manufacturer or trade company?

A:We are a manufacturer in package machine field since 2002, located at Jintan ,Changzhou, near Shanghai, We will pick you up to visit our factory.

Q:Do you have any certification?

A:SGS,ISO,CE

Q:What about the delivery time?

A:Usually 30 Working days

Q:What about the machine's capacity?

A:according to differnent machines' type, 800-4000 bottles in 1000ml per hour.

Q:The after-sale service

A: 12 months warranty to change the spare parts which are damaged by non-human factors for free.

solve basic questions by telephone, email, whatsapp, wechat and video call.

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines.

Operating manuals will be sent with machine or by email.

We also have overseas service center

Q: If I want to buy a machine, what information do I need to tell you?

A:a. What kind product you want to pack?

b. bottle volume: 250ml, 330ml, 500ml, 750ml, 1L, 2L, 5L, 20L etc.?

c. Producing capacity requirement? How many bottles you want to pack per hour?

d. Pictures of your products' bottles and caps

e. Voltage and altitude.

Q:What kinds of product you supply?

A: Our maim products as follows: foodstuff, seasoning, wine filling line, daily chemical, cosmetic filling line, pesticide, fine

chemical filling line and oils filling lines. Products category: automatic bottle feeder, bottle washing machine, filling machine, capping machine, lid-presser, label machine, shrink label machine, sealing machine, ink-jet printer, case packer, wrapping machine, carton sealing machine and full-automatic intellectual level complex film bagging packer, totally ten series and more than thirty kinds of products.

A:We are a manufacturer in package machine field since 2002, located at Jintan ,Changzhou, near Shanghai, We will pick you up to visit our factory.

Q:Do you have any certification?

A:SGS,ISO,CE

Q:What about the delivery time?

A:Usually 30 Working days

Q:What about the machine's capacity?

A:according to differnent machines' type, 800-4000 bottles in 1000ml per hour.

Q:The after-sale service

A: 12 months warranty to change the spare parts which are damaged by non-human factors for free.

solve basic questions by telephone, email, whatsapp, wechat and video call.

Engineer will go to buyer's factory to install, test machines, and train buyer's staff how to operate, maintain machines.

Operating manuals will be sent with machine or by email.

We also have overseas service center

Q: If I want to buy a machine, what information do I need to tell you?

A:a. What kind product you want to pack?

b. bottle volume: 250ml, 330ml, 500ml, 750ml, 1L, 2L, 5L, 20L etc.?

c. Producing capacity requirement? How many bottles you want to pack per hour?

d. Pictures of your products' bottles and caps

e. Voltage and altitude.

Q:What kinds of product you supply?

A: Our maim products as follows: foodstuff, seasoning, wine filling line, daily chemical, cosmetic filling line, pesticide, fine

chemical filling line and oils filling lines. Products category: automatic bottle feeder, bottle washing machine, filling machine, capping machine, lid-presser, label machine, shrink label machine, sealing machine, ink-jet printer, case packer, wrapping machine, carton sealing machine and full-automatic intellectual level complex film bagging packer, totally ten series and more than thirty kinds of products.

Contact US :

Fiona Ding (Sales Manager)

Fiona Ding (Sales Manager)

Mobile : 0086-13685270809 (whatsapp)

Email : fiona@ztpack.net

zt-pack@hotmail.com

Company Name : Jiangsu ZhongTai Packing Machinery Co.,ltd

( ZT-PACK )

Address : No. 16, He Shan Huan Road, Industrial Zone , Jintan District, Changzhou City, Jiangsu Province, P. R. China

Post Code : 213200

Tel:+86-519-82112618

Fax:+86-519-82113618

www.ztpack.net

www.ztchina.net

zt-pack@hotmail.com

Company Name : Jiangsu ZhongTai Packing Machinery Co.,ltd

( ZT-PACK )

Address : No. 16, He Shan Huan Road, Industrial Zone , Jintan District, Changzhou City, Jiangsu Province, P. R. China

Post Code : 213200

Tel:+86-519-82112618

Fax:+86-519-82113618

www.ztpack.net

www.ztchina.net

www.zt-pack.com

Hot Searches