- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

DW-M

-

Thickness:

-

1.2-6mm

-

Size:

-

1220*2440mm

-

Color:

-

Customized

-

Application:

-

interior walls for restaurent,hotel,kitchen,washing room,etc.

-

Product name:

-

Clear PVC Sheet

-

Feature:

-

Waterproof

-

Width:

-

1220mm-1250mm

-

Length:

-

2440mm-5800mm

-

Grain:

-

marble grains and wooden colors

-

PVC content:

-

40%,50%,60%,etc.

-

Surface:

-

uv coating with hot stamping

-

Usage:

-

Wall decoration

Quick Details

-

Processing Service:

-

Cutting, Moulding

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DOWELL

-

Model Number:

-

DW-M

-

Thickness:

-

1.2-6mm

-

Size:

-

1220*2440mm

-

Color:

-

Customized

-

Application:

-

interior walls for restaurent,hotel,kitchen,washing room,etc.

-

Product name:

-

Clear PVC Sheet

-

Feature:

-

Waterproof

-

Width:

-

1220mm-1250mm

-

Length:

-

2440mm-5800mm

-

Grain:

-

marble grains and wooden colors

-

PVC content:

-

40%,50%,60%,etc.

-

Surface:

-

uv coating with hot stamping

-

Usage:

-

Wall decoration

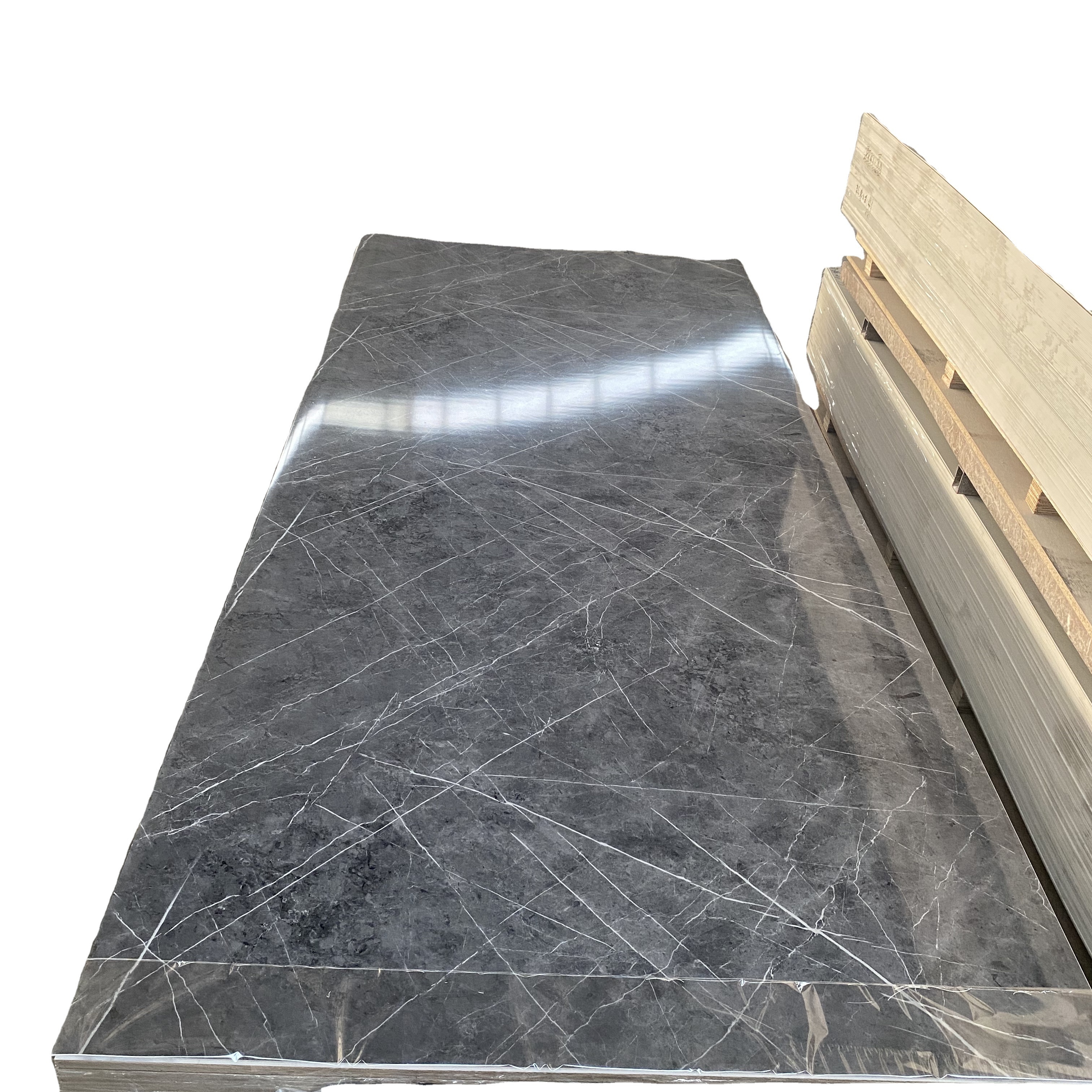

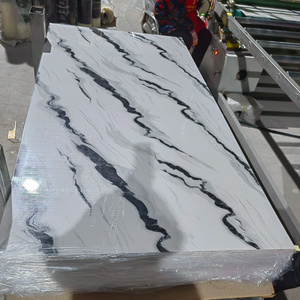

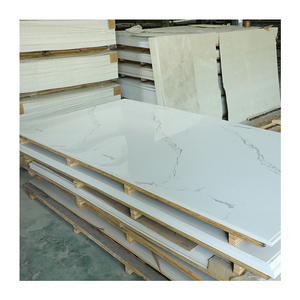

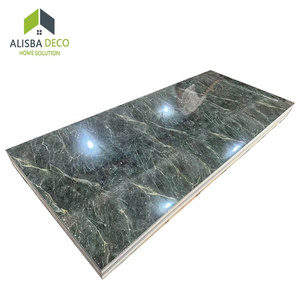

PVC Marble Plastic Imitation Marble Sheet PVC Wall Panel Sheet

| Material | PVC,CaCO 3 ,and additive |

| Technology | Heat transfer print, uv curing |

| Size | 1220X2440mm; thickness:1.2-6mm |

| Color | 1. Marble stone, wooden grain, solid color and 3D |

| 2. Custom-designed color is accepted | |

| installation | Glue on the wall |

| Feature | Environmental protection,fire-retardant(B1 class),waterproof,wear resistant(3H), non-formaldehyde, high glossy,ideal material for interior decoration |

| Certificate | CE,SGS and ISO |

| Application | Interior decoration for commercial and residential places |

| Sample | Samples are free, you just pay the courier fee |

| QTY in 20ft | 100 pcs/pallet, 800 -1400 pcs for one 20ft (according to thickness) |

| Package | Wood pallet + corner protection + metal strap |

| Payment Term | T/T 30% deposit at least |

| Delivery Time | Within 20-25days after the order confirmed with 30% deposit |

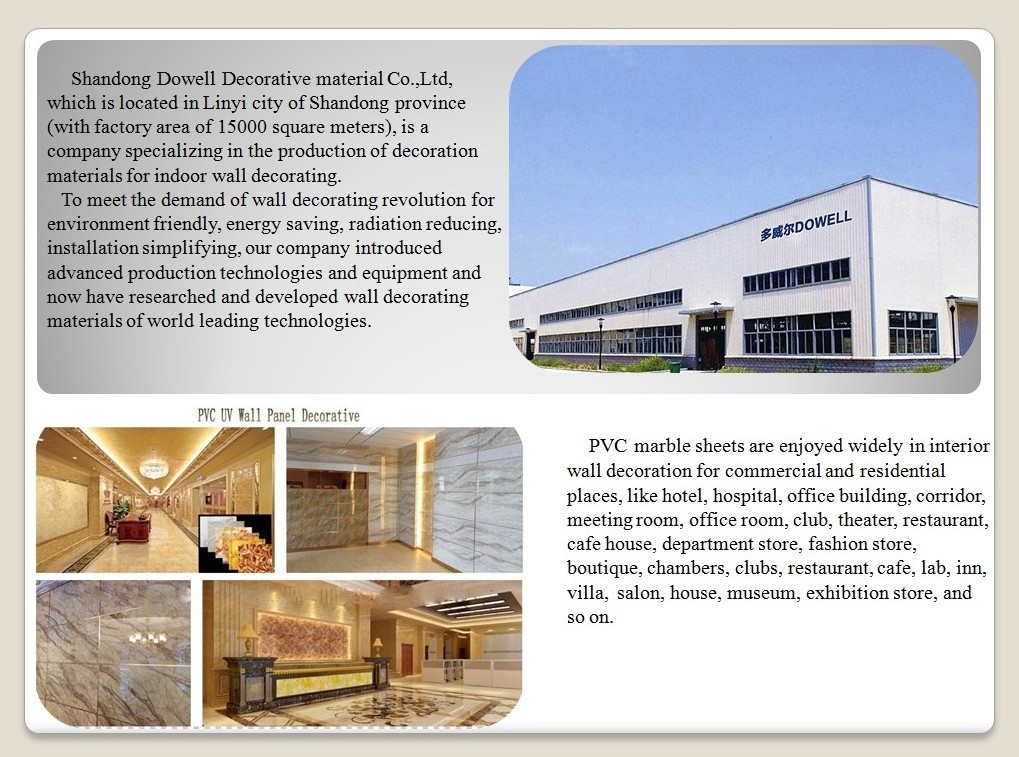

PVC marble sheets are enjoyed widely in interior wall decoration for commercial and residential places, like hotel, hospital, office building, corridor, meeting room, office room, club, theater, restaurant, cafe house, department store, fashion store, boutique, chambers, clubs, restaurant, cafe, lab, inn, villa, salon, house, museum, exhibition store, and so on.

Integrated Wall Panel---Decorative Strips

Method 1: A luminum alloy fixed

1. First, cover a basic layer on the wall. The most commonly used are the 3MM plywood and wood board.Fireproof glassy magnesium board is much better. They are nailed to the wall with air nails.

2. Peg the foot line on the wall, fix the corner with aluminum alloy feet, then use the aluminum alloy tool bar to fix the corner. In other words, nailing the aluminum alloy inner corner and the aluminum alloy tool bar to the corresponding position on the wall respectively.

3. According to the required size,cut up a UV plate into several boards with the saw. The edges are trimmed and cleaned with sandpaper.

4. Insert the UV plate between the aluminum alloy inner corner and the tool bar.

Method 2 :Install with wall glue

1. First of all, you should put a base on the wall, commonly use for 3MM plywood, wood board, and better for fireproof glass magnesium plate, which will be fixed on the wall with air nails and clean up the wall with sandpaper.

2.To cut the UV board into pieces according to actual requirements from the plate.

3.Reverse side, the UV plate will be cut into the 45 degree angle by machine. According to the actual installation requirements, some only need to reverse the upper and lower sides or three sides.

4.Clean the surface of UV panel ,clean the backside of panel by Sandpaper or duster.

5.Apply the universal glue or woodworking glue to the back of UV, then place the UV plate on the wall, and then gently beat the UV plate with your hand, so that the UV board can be firmly adhered to the wall.

6.Joint sealant, joint sealant filled in two UV plate 45 degree angle intersect, fill first, reoccupy board from 45 degree angle intersect lightly across vertically, it would look better with 45 degree angle intersect.

Any questions,pls feel free to contact me.

Ms Janice

Mob.&Wechat&Whatsapp: +86 135 8108 3792