- Product Details

- {{item.text}}

Quick Details

-

output size(mm):

-

150-300MM

-

warrenty of jaw crusher:

-

one year

-

application:

-

Granite, Basalt, River Stone, Iron Ore, Copper Ore etc.

-

bearing brand:

-

as customer's requirment, japanese NSK

-

motor:

-

as customer's requiment, simens

-

Product Name:

-

Jaw Crusher

-

overseas service:

-

24 hours

-

mobile wheel:

-

can be installed on mobile wheel

-

Certification:

-

BV,ISO

Quick Details

-

Place of Origin:

-

Henan, China

-

After-sales Service Provided:

-

Overseas service center available, Online support

-

input size(mm):

-

1020MM

-

output size(mm):

-

150-300MM

-

warrenty of jaw crusher:

-

one year

-

application:

-

Granite, Basalt, River Stone, Iron Ore, Copper Ore etc.

-

bearing brand:

-

as customer's requirment, japanese NSK

-

motor:

-

as customer's requiment, simens

-

Product Name:

-

Jaw Crusher

-

overseas service:

-

24 hours

-

mobile wheel:

-

can be installed on mobile wheel

-

Certification:

-

BV,ISO

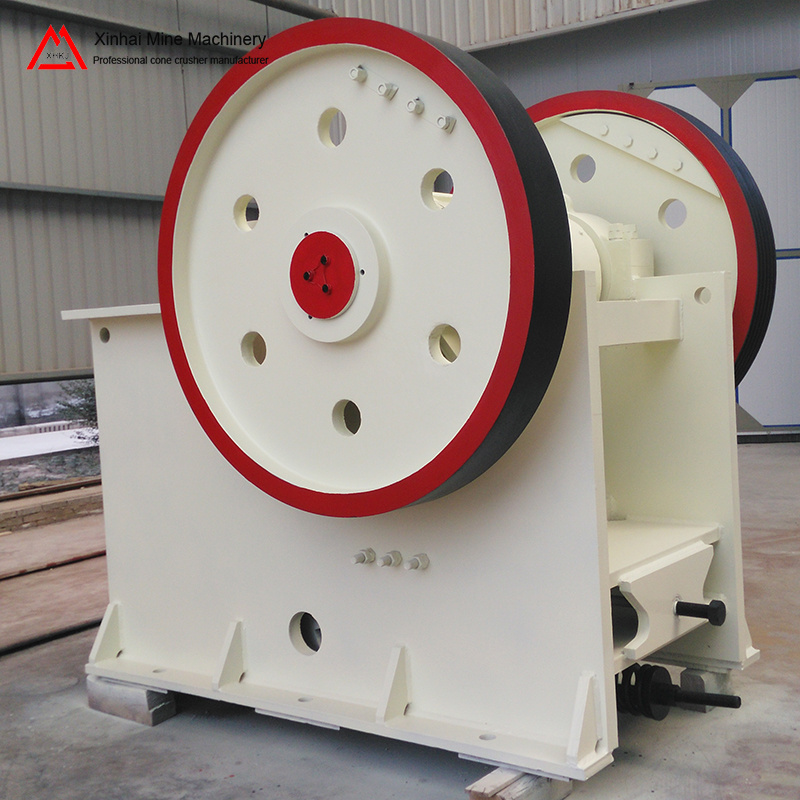

Stone Jaw Crusher Used In Mining Heavy Industry Equipment

Jaw Crusher is ideally suitable for primary and secondary crusher for material with compression strength less than 320MPA. Jaw Crusher is of high crushing ratio, larger capacity, well-distributed final product size, simple structure, reliable performance, convenient maintenance, lower operation cost, etc. It is widely used in mining, metallurgy, construction, highway, railroad, and water conservancy, etc.

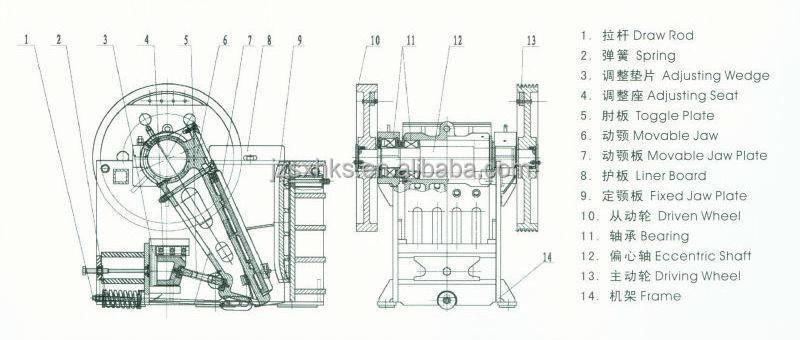

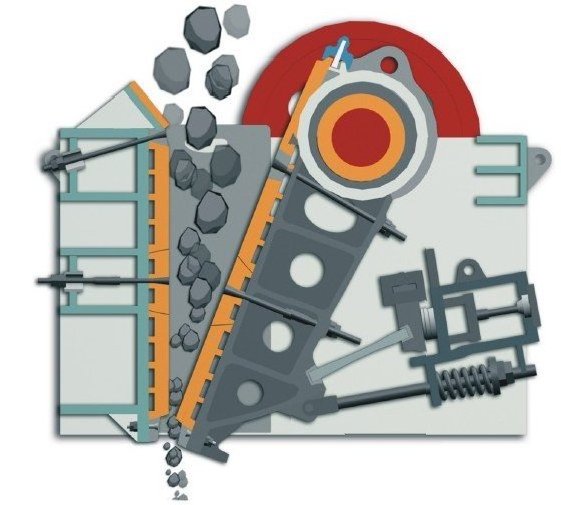

Working principle of Jaw Crusher Machine

The electrical motor transmits power to the eccentric shaft through v-belt and belt pulley. Then the exciting force generated by the eccentric shaft will make the movable jaw move upwards and downwards. This movement would trigger the toggle plate to push the movable jaw forwards and backwards. When the movable jaw moves forth towards the fixed jaw, materials in the crushing cavity will be squashed or chopped. And then the movable jaw travels back, the chopped or squashed materials which meet the requirement will be discharged from the outlet. Since the motor keeps working. The crusher will crush and discharge periodically to achieve mass production.

Features and advantages of Stone Crusher Machine

1. High crushing ratio, well-distributed final product size.

2. Discharge opening of the jaw crusher is adjustable reliably within a wide range through the stuffing of shim, thus it is capable to meet various requirements of customers.

3. lubrication system of it is safe and reliable, which boasts an easy and convenient maintenance.

4. simple structure, reliable performance, low maintenance cost.

5. little dust and low noise.

Specifications of Stone Crusher Machine(Jaw Crusher)

|

Model |

Feeding Size

(mm) |

Max Feeding Size

(mm) |

Discharging Size

(mm) |

Capacity

(m3/h) |

Motor Power

(kw) |

Weight

(t) |

| PE250*400 | 250*400 | 210 | 20-60 | 3-13 | 15 | 2.8 |

| PE400*600 | 400*600 | 340 | 40-100 | 10-35 | 30 | 6.5 |

| PE500*750 | 500*750 | 425 | 50-100 | 25-60 | 55 | 10.6 |

| PE600*900 | 600*900 | 500 | 65-180 | 30-85 | 55-75 | 15.5 |

| PE750*1060 | 750*1060 | 630 | 80-180 | 72-150 | 90-110 | 28 |

| PE800*1060 | 800*1060 | 680 | 100-200 | 85-143 | 90-110 | 30 |

| PE870*1060 | 870*1060 | 750 | 170-270 | 145-235 | 90-110 | 30.5 |

| PE900*1060 | 900*1060 | 780 | 200-290 | 170-250 | 90-110 | 31 |

| PE900*1200 | 900*1200 | 780 | 95-225 | 100-240 | 110-132 | 49 |

| PE1000*1200 | 1000*1200 | 850 | 195-280 | 190-275 | 110-132 | 51 |

| PE1200*1500 | 1200*1500 | 1020 | 150-300 | 250-500 | 160 | 100.9 |

| PEX150*750 | 150*750 | 120 | 18-48 | 5-16 | 15 | 3.5 |

| PEX250*750 | 250*750 | 210 | 25-60 | 8-22 | 22 | 4.9 |

| PEX250*1000 | 250*1000 | 210 | 25-60 | 10-32 | 30-37 | 6.5 |

| PEX250*1200 | 250*1200 | 210 | 25-60 | 13-38 | 37 | 7.7 |

| PEX300*1300 | 300*1300 | 250 | 20-90 | 10-65 | 75 | 11 |

Note: the processing capacity is described on the basis of data about processing mid-hard materials and the bulk density of crushed materials is 1.6t /m3

QUALIFICATION HONORS

Your email address and telephone will not be shared or published!

Please fill in your need products and your message and do not forget mail and/or phone if you like to be contacted.

we are the professional machine manufacturer in China.

I need to ask you some details for sending you the more suitable quotation,

1.what is the raw material do you want to process?

2.what is the capacity per hour do you need?

3.what is the raw material input size?

4.what is the output size of your product?

Of course, free live-chat is available and you can get help immediately.Or you can send me email .

You can get the price list and a Xinhai representative will contact you within one business day.

I hope you can tell me these details,i will give you the best quotation ASAP ,thanks. Your satisfaction is our greatest pursuit, we would like to sincerely for your service! We look forward to your inquiry!

Contact us :

Tel:+86-371-67660555

Website: www.hicrusher.com

Factory Address : Boai Industrial District, Jiaozuo City, Henan Province, China

Marketing Center Address : Room 609,East Tower of Xiyuan International Plaza,Jianshe Road,Zhengzhou,China