- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Could be customized

-

Dimension(L*W*H):

-

depends on specific model

-

Weight:

-

22000 KG

-

Application area:

-

Copper Ore Processing Plant

-

Processing Capacity:

-

Any capacity customizable

-

Feeding size:

-

Depend on the ore size

-

Layout drawing on site:

-

Provided

-

Engineer field installation:

-

Provided

-

Diesel generator:

-

Available to sell

-

Other ores separation plant:

-

Provided

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Engineer Site Installation:

-

Provided

-

Certification:

-

ISO, CE

Quick Details

-

Production Capacity:

-

98%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JXSC

-

Voltage:

-

Could be customized

-

Dimension(L*W*H):

-

depends on specific model

-

Weight:

-

22000 KG

-

Application area:

-

Copper Ore Processing Plant

-

Processing Capacity:

-

Any capacity customizable

-

Feeding size:

-

Depend on the ore size

-

Layout drawing on site:

-

Provided

-

Engineer field installation:

-

Provided

-

Diesel generator:

-

Available to sell

-

Other ores separation plant:

-

Provided

-

After-sales Service Provided:

-

Field maintenance and repair service

-

Engineer Site Installation:

-

Provided

-

Certification:

-

ISO, CE

Overview

Application

Features

three-stage-crushing with single closed circuit stage process to reduce the load of the grinding system.

3.Pneumatic flotation machine is used to ensure the flotation effect Pneumatic fiotation machine is adopted to obtain good ore beneficiation indicators.

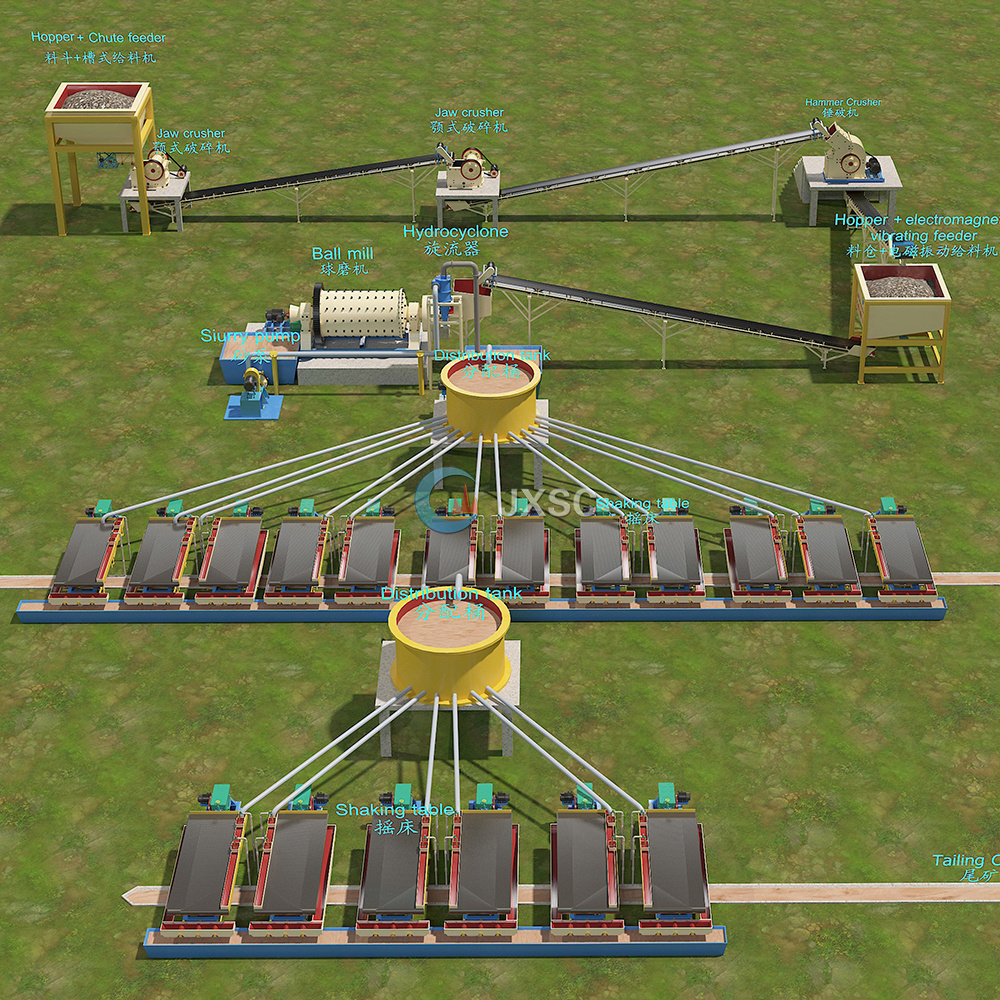

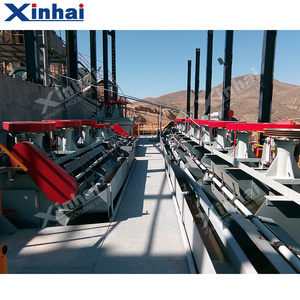

This JXSC Processing plant Setup is Rock Copper Gravity Separation Plant. Complete set include Feeding Hopper, Chute Feeder, Rough Jaw crusher, Fine Jaw crusher, Hammer crusher, belt conveyor, Copper Concentration Shaking table,ect. This designed flowchart is suitable to process Oxide type and Sulfide type copper, and man other minerals , such as rock gold, rock Chrome ore , rock coltan ore, rock tin ore, rock Mn ore, rock zinc lead, ect. The flowchart can be designed according to customer’s minerals real conditions and requirements for plant.

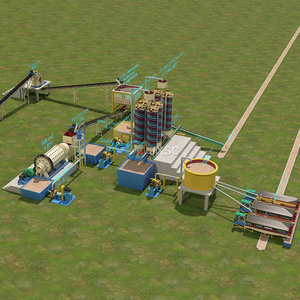

This JXSC Setup is complete set Rock Copper Processing plant, including crushing, grinding, gravity separation, copper concentrate ore dewatering system, tailing water recycle system,ect. Main machines include feeding hopper, chute feeder, primary jaw crusher, secondary jaw crusher, impact fine crusher, ball mill, spiral chute, shaking table, cone thickener for concentrate, plate filter press, thickener for tailings. This designed plant is high recovery ratio and effect for recovery Oxide type rock copper and many other type minerals, such as rock chrome ore, rock Mn ore, Rock Zinc Lead,ect. The plant design can be adjustable according to material conditions and requirements.

|

1.Small parts packed in the wooden cases

|

|

2.Big parts packed by plastic membrane

|

|

3.The whole big machine is loaded in the container

|

experiences,providing complete set processing equipments for Gold ore /Tin ore /Tungsten ore /Iron ore /Diamond/ Coltan ore /Silica sand /Zircon sand/ Black sand/Chrome ore/Cobalt ore/Antimony ore, ect. As well as complete set small laboratory mining machines.

manufacturer equipment according to your special demand.

●Pre-sales service: We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

●Sales service:

Send technicians to the site to guide the installation and commissioning, train the operators, and complete the acceptance with you.

●After-sales service:

To establish long term friendship, we will regularly pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

●Lifelong service:

One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term.

● How is the quality of your products?

●

How about the Guaranteed?

Answer:

All of our products are guaranteed for one year. If products quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

●

How about price?

Answer:

For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

●

How about the service and payment terms?

Answer:

We can accept T/T or other payment ways you request; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.