- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Futian

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

based on model

-

Weight:

-

based model on

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

double-wall corrugated pipe production line

-

Raw material:

-

PP PE Granules

-

Processing Type:

-

Pipe Extrusion

-

Motor:

-

SIEMENS Brand

-

Inverter:

-

ABB Brand

-

Cooling method:

-

Pressure water cooling system

-

Mandrel:

-

Aluminium alloy

-

Material:

-

Stainless Steel 304

-

Color:

-

Selectable

-

Warranty:

-

1 Year

-

Certification:

-

CE ISO SGS

-

Automatic Grade:

-

Automatic

-

Power:

-

280-450kw

Quick Details

-

Screw Design:

-

Single-screw

-

Model Number:

-

BW-II

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Futian

-

Voltage:

-

380V 50HZ 3Phase(Customized)

-

Dimension(L*W*H):

-

based on model

-

Weight:

-

based model on

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

double-wall corrugated pipe production line

-

Raw material:

-

PP PE Granules

-

Processing Type:

-

Pipe Extrusion

-

Motor:

-

SIEMENS Brand

-

Inverter:

-

ABB Brand

-

Cooling method:

-

Pressure water cooling system

-

Mandrel:

-

Aluminium alloy

-

Material:

-

Stainless Steel 304

-

Color:

-

Selectable

-

Warranty:

-

1 Year

-

Certification:

-

CE ISO SGS

-

Automatic Grade:

-

Automatic

-

Power:

-

280-450kw

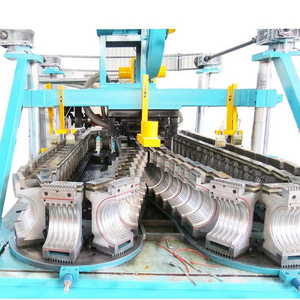

double wall HDPE corrugated pipe production line

Description of the production line:

SGB800 (inner diameter Φ200-Φ800mm) double wall corrugated pipe production line has two single-screw extruder. It has a dual-channel structure and nitriding polishing head. The forming machine adopts horizontal (or vertical) structure , advanced water cooling system, vacuum forming system, automatic lubrication system and advanced double-layer on-line expansion function. The material of the molds is aluminum alloy. The complete production line uses the German Siemens professional PLC control system. It has a high degree of automation, reliable operation, easy operation and so on.

Characteristics of the double wall corrugated pipe:

The production line uses HDPE / PE or PVC as raw materials. The inner wall of the double wall corrugated pipe produced by this production line is very smooth and flat. And the outer wall is trapezoidal corrugated shape. The kind of double wall corrugated pipe has the characteristics of good corrosion resistance, high insulation, small flow resistance etc. as the ordinary plastic pipe, but also because of special inner and outer wall hollow ring structure, it has the advantages of high rigidity, light weight, high pressure resistance, good toughness, abrasion resistance, impact resistance, not easy damage, convenient construction, low installation cost, long service life, etc.

Application of the double wall corrugated pipe:

The double wall corrugated pipe is generally connected by the expansion socket and the sealing ring. This can effectively prevent the impact of thermal expansion and contraction. The double wall corrugated pipe is widely used in the fields of highway, railway roadbed, subway engineering, waste landfill, tunnel, green belt, sports field and high water content caused by the slope protection and other drainage areas.

Main technical parameter:

| Model | SGB160 | SGB250 | SGB400 | SGB600 | SGB800 |

| Structure Form | Horizontal | Horizontal | Horizontal | Vertical | Vertical |

| Pipe Diameter Range(mm) | 75-160 | 90-250 | 225-400 | 250-600 | 225-800 |

| Expansion Mode | Belling-on-line, double-wall socket joint | Belling-on-line, double-wall socket joint | Belling-on-line, double-wall socket joint | Belling-on-line, double-wall socket joint | Belling-on-line, double-wall socket joint |

| Forming Speed(m/min) | 0.6-5 | 0.5-5 | 0.25-4 | 0.25-4 | 0.25-3 |

| Max. Extrusion Output | 200 | 350 | 600 | 700 | 850 |

| Number of Mold Blocks(pairs) | 48 | 48 | 40 | 32 | 32 |

| Centre Height(mm) | 1000 | 1150 | 1150 | 1600 | 1600 |

Photos Show:

double wall HDPE corrugated pipe production line

Certifications:

Packaging & Shipping:

Our service:

Turn key project

Technical documents

We will offer you all necessary documents, e.g. general layout plan, water scheme, electrical diagram and user manual after the contract is executed.

Arrangement for inspection, installation and testing work

After being informed machines ready for inspection, customer can send engineers to our factory.

After the machines are delivered to customer’s factory, we will send one or two technicians to the factory after preparation work is completed. Technicians will be responsible for guide on-site installation and testing machines.

Meanwhile technicians will give free training lessons to labors in customer’s factory.

After one year quality guarantee period, we will provide after-sell service for all the life.

Our company is near Shanghai International Airport, about 130km. Welcome you to visit our factory and Running machines can be showed at any time!