- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

NaiDi

-

Model Number:

-

E6013

-

Operating Current:

-

none

-

Application:

-

copper, stainless steel, steel etc.

-

Product Name:

-

Carbon Steel Welding Electrodes

-

Usages:

-

Welding Carbon Steel Structure

-

Keyword:

-

CARBON WELDING ELECTRODE AWS E6013

-

Color:

-

Grey

-

Advantage:

-

Small Splash

-

Type:

-

Welding Electrode E6013 7018

-

Certification:

-

ISO9001

-

Package:

-

25KG/Carton

-

Standard:

-

AWS A.5.1 E6013

-

Packing:

-

5kgs/inner Box

Quick Details

-

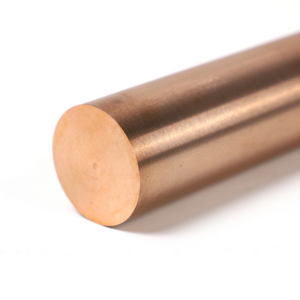

Material:

-

Copper / Copper Alloy

-

Welding Current:

-

none

-

Operating Temperature:

-

600-800

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

NaiDi

-

Model Number:

-

E6013

-

Operating Current:

-

none

-

Application:

-

copper, stainless steel, steel etc.

-

Product Name:

-

Carbon Steel Welding Electrodes

-

Usages:

-

Welding Carbon Steel Structure

-

Keyword:

-

CARBON WELDING ELECTRODE AWS E6013

-

Color:

-

Grey

-

Advantage:

-

Small Splash

-

Type:

-

Welding Electrode E6013 7018

-

Certification:

-

ISO9001

-

Package:

-

25KG/Carton

-

Standard:

-

AWS A.5.1 E6013

-

Packing:

-

5kgs/inner Box

Chemical composition of deposited metal (%)

|

Cu |

Si |

Mn |

P |

Pb |

Fe+Al+Ni+Zn |

|

>9 2 .0 |

2.5-4.0 |

≤ 1.5 |

≤0.30 |

≤0.02 |

≤0. 50 |

Mechanical properties of deposited metal (reference values)

|

Experimental projects |

Tensile Strength MPA |

Elongation % |

|

guarantee value |

≥ 270 |

≥20 |

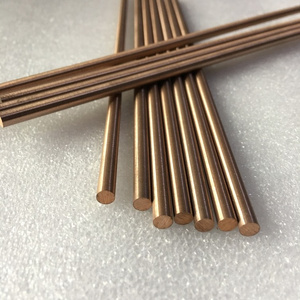

Reference current: DC+

|

Diameter of welding rod(MM) |

2.5 |

3.2 |

4.0 |

5.0 |

|

Welding Current (A) |

70-110 |

90 -1 3 0 |

1 1 0-1 6 0 |

1 5 0-200 |

Notes: 1. The electrode must be baked at 350-400 ° C for 1-2 hours before welding.

2. The water, oil, oxide and other impurities on the welding surface must be cleaned before welding.

3. No preheating is required when welding silicon bronze or surfacing on steel. The preheating of pure copper is 450 ° C, and that of welded brass is 300 ° C.

4. After welding, Hammer the weld with flat head to refine the grain, eliminate the stress and improve the strength and plasticity of the weld.

About Us:

1. What are our main products?

The main products are welding rod, wire, solder, flux, alloy powder and

other five categories, more than 100 kinds of products. Among them,

welding electrodes include nickel-based cast iron electrode, copper

and copper alloy electrode, cobalt-based surfacing electrode, nickel

and nickel alloy electrode; brazing fillers include copper-zinc, copperphosphorus and silver-based filler metals; fluxes include gas welding and

brazing, silver, copper, aluminum and other flux; alloy powder includes

spray welding and spraying, including nickel-based, cobalt-based,

iron-based and other varieties. The products are manufactured in full

accordance with American Standards (AWS).

2. Why did you choose our company ?

our company can organize R&D, trial production and supply in time according to the special needs of users. Our products are advanced in production technology, with the first-class inert gas protected continuous casting production line in China, vertical, horizontal hot extrusion, continuous tie, continuous pull, polishing production equipment, ultrasonic cleaning and other production lines and complete testing equipment.