- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1500*900*1400

-

Year:

-

Product after order

-

Power (kW):

-

55 kW

-

Weight (KG):

-

13000 KG

-

Name:

-

full automatic tire recycling production line

-

After-sales Service Provided1:

-

Engineers available to service machinery overseas

-

Factory direct sales:

-

With competitive price and high quality

-

Rubber mesh:

-

28-30

-

Power(W):

-

55kw

-

Weight:

-

13000kg

-

After-sales Service Provided2:

-

Free spare parts

-

After Warranty Service:

-

Online support

-

Certification:

-

CE ,ISO

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

CGY

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

1500*900*1400

-

Year:

-

Product after order

-

Power (kW):

-

55 kW

-

Weight (KG):

-

13000 KG

-

Name:

-

full automatic tire recycling production line

-

After-sales Service Provided1:

-

Engineers available to service machinery overseas

-

Factory direct sales:

-

With competitive price and high quality

-

Rubber mesh:

-

28-30

-

Power(W):

-

55kw

-

Weight:

-

13000kg

-

After-sales Service Provided2:

-

Free spare parts

-

After Warranty Service:

-

Online support

-

Certification:

-

CE ,ISO

-

Marketing Type:

-

Ordinary Product

full automatic tire recycling production line tire recycling machine to make rubber powder price

1. General:

This production line including main machine and accessorial equipment, it is used for recycling scrap-tire (steel tyre and textile tyre), the final product is rubber powder or reclaimed rubber.

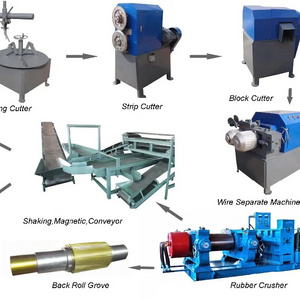

2.Process flow:

Waste tire - Tire wire drawing machine - Whole tire cutting - Tire shredding - Tire crushing - Magnetic separator - Fiber separator - Rubber powder

the whole line has the following features:

1), iron/steel removing ratio>99.5%, fiber removing ratio>98%

2),compact structure ensure running safety, easy maintenance;

3),low energy consumption;

4),adopt automatic control system for whole line, reduce labor cost;

5),no sewage and waste gas discharge, environment protection.

6), available capacity range of our tire recycling lines at present: 400~3000kg/h

7), available finial rubber powder size: 30~120mesh.

8), adopts SIEMENS and Chinese famous brand electrical elements.

3.Processing method:

Physic mechanical crushing method at normal temperature of waste tyre:nochemical raw material is required,no waste gas,washte water and soot are discharged, and the cooling water of the equipment is reused,no emission,equipment noise is within the range specified by the country(GB20055-2006),fineness of rubber powder produced by it is adjustable(10 meshes to 30 meshes),take waste tyre as example,the process is as follows:breaking down,crushing,filtering,magnetic separating,grin-ding,then the finished products are produced.

4.Main Parameters

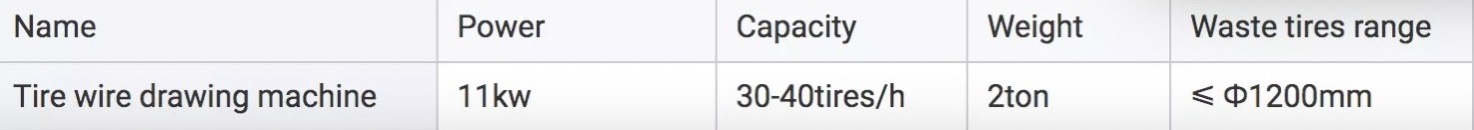

Tire wire drawing machine(To draw out the rim steel from tire bead)

Whole tire shredding machine ZPS- 800,1200

Use:This machine can directly crush tires smaller than 1200mm tires. At the general temperature, can be put directly crushed into 50 * 50 mm block, so the next rotating can grind into 10-30 meshes or wire and fiber separation equipment.

Photo of ZPS-900

Photo of ZPS-1200

Photo of knife

Tire Cutter QDJ-1200

Application:

Cut whole tire which more than 1200mm into 3-4 pieces.

Highlights

1.big knife with well cutting performance, fast speed

2. low energy consumption

3.small in size

4 . hydraulic system to ensure the safety and easy operation

Main parameters

Exibition & Customers