1. Please clean filter shell carefully before using.

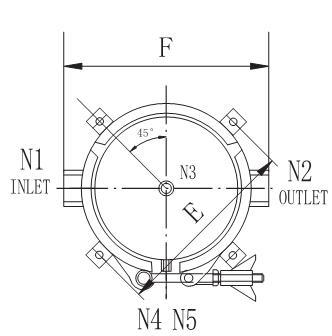

2. Connect cartridge filter with other in-line filtering system. Please check inlet and outlet install direction.

3. Open the filter top cover to check cartridge condition: O-ring’s sealing and its position.

4. Users can use wetting agent (Water e.g) to wet O-ring and cartridge socket.

5. Hold the cartridge near O-ring side, insert it into socket vertically.

6. Insert all cartridges, fixing with press plate and covering with top cover.

Open vent valve at the top of out shell. Turn on inlet valve a bit, let liquid into shell. Turn off vent valve till liquid comes into shell entirely and leak from vent valve. Adjust outlet valve gradually until turn on it fully. Turn on inlet valve slowly to adjust pressure drop to a data of 0.02MPa.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

0-200kg

-

Size:

-

Customized

-

Power:

-

<1

-

Productivity:

-

0-1000m3/h

-

Weight (KG):

-

200 kg

-

Max working pressure:

-

1.0MPa,1.6Mpa

-

Electricity and power:

-

no need

-

Inlet and outlet:

-

1-14 inch or customized

-

Application:

-

beer,milk,industrial water,mineral water

-

Filter degree:

-

1-500microns

-

Filter area:

-

0.25-12M2

-

Filter basket:

-

stainless steel

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

peide

-

Material:

-

Wooden box, SS304 or 316L

-

Weight:

-

0-200kg

-

Size:

-

Customized

-

Power:

-

<1

-

Productivity:

-

0-1000m3/h

-

Weight (KG):

-

200 kg

-

Max working pressure:

-

1.0MPa,1.6Mpa

-

Electricity and power:

-

no need

-

Inlet and outlet:

-

1-14 inch or customized

-

Application:

-

beer,milk,industrial water,mineral water

-

Filter degree:

-

1-500microns

-

Filter area:

-

0.25-12M2

-

Filter basket:

-

stainless steel

Cartridge filter, also known as security filter. The shell is made of high quality stainless steel, filter using molded filter, The liquid went through filter under pressure, residue left on the filter, and the filtrate outflow through the filter can effectively remove impurities in the water, sediment and suspended solids, bacteria. Molded filters are: cloth, screen, filter, sintered filter tube, wound filter, melt-blown filter, micro-porous filter and multi-function filter.Due to different filter, the filter pore size is not the same. Precision filter is between the sand filter (coarse) and a filter between ultra-filtration, filter pore size generally between 0.01-120um.For the same form of filter,it is divided into different models by their dimensions.

Product Parameters

|

Working pressure:

|

0.6 / 1.0 / 1.6Mpa

|

|

Body Material:

|

Stainless steel (SUS304, SUS304L, SUS316, SUS316L).

|

|

Operating temperature:

|

5 ~ 40 ℃ (exceed 60 ℃ to be informed)

|

|

Design temperature:

|

5 ℃ -100 ℃

|

|

Replace the pressure:

|

0.05Mpa-0.07MPA

|

|

Filter interface:

|

flat compression, plug-in

|

|

Filtration accuracy:

|

1μm ~ 100μm

|

|

Cartridge Quantity:

|

1 core to 180 cores

|

|

Filter Length:

|

10 "~ 40"

|

|

Seal type:

|

O-ring or flat washer

|

|

Seal Material:

|

PTFE, rubber.

|

|

Outside treating :

|

matte jet beads, mirror electrolytic polishing.

|

|

Sealing material:

|

nitrile rubber, silicone, Viton, standard configuration for the silicone seal.

|

|

Interface Type:

|

GB, HG, DIN, ANSI, JIS standard flanges, dental mouth, clamps and so on.

|

|

Flange Standard:

|

GB, HG, SH, HGJ, JB, ANSL, JIS and other standards.

|

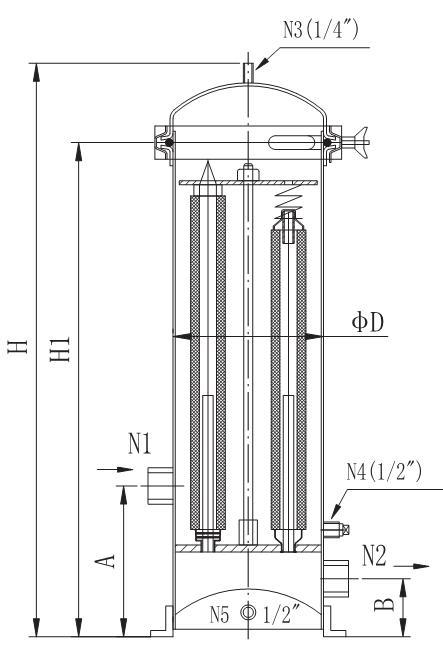

Equipment Model

|

Model

|

ΦD

|

A (mm)

|

B(mm)

|

H(mm)

|

N1/N2Φ

|

(m³/H)

|

|

JLQ10-30"

|

Φ 300

|

180

|

60

|

1050

|

2.5"

|

15

|

|

JLQ10-40"

|

Φ 300

|

180

|

60

|

1500

|

2.5"

|

20

|

|

JLQ15-30"

|

Φ 350

|

250

|

120

|

1050

|

2.5"

|

22

|

|

JLQ15-40"

|

Φ 350

|

250

|

120

|

1500

|

3"

|

30

|

|

JLQ20-30"

|

Φ 400

|

250

|

120

|

1100

|

3"

|

30

|

|

JLQ20-40"

|

Φ 400

|

250

|

120

|

1550

|

3"

|

40

|

|

JLQ25-30"

|

Φ 450

|

1050

|

300

|

1630

|

3"

|

37

|

|

JLQ25-40

|

Φ 450

|

1200

|

350

|

2030

|

4"

|

50

|

|

JLQ30-30"

|

Φ 500

|

1050

|

350

|

1800

|

4"

|

45

|

|

JLQ30-40"

|

Φ 500

|

1200

|

350

|

2150

|

4"

|

60

|

|

JLQ40-30"

|

Φ 600

|

1050

|

400

|

1900

|

4"

|

60

|

|

JLQ40-40"

|

Φ 600

|

1200

|

400

|

2150

|

5"

|

80

|

|

JLQ50-30"

|

Φ 700

|

1050

|

400

|

1950

|

5"

|

75

|

|

JLQ50-40"

|

Φ 700

|

1200

|

400

|

2200

|

6"

|

10

|

|

JLQ65-30"

|

Φ 800

|

1200

|

400

|

2000

|

6"

|

97

|

|

JLQ65-40"

|

Φ 800

|

1350

|

400

|

2250

|

6"

|

130

|

|

JLQ80-40"

|

Φ 900

|

1350

|

450

|

2350

|

8"

|

160

|

|

JLQ100-40"

|

Φ 1000

|

1350

|

500

|

2450

|

10"

|

200

|

Installation steps

Details Images

Production Process

Hot Searches