<1>All 304/316stainless steel rinse heads, water spray style inject design, more save water consumption and more clean

<2>304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

<3> 304/316 stainless steel washing pump

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±2mm

-

Voltage:

-

110-415V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

beierde

-

Dimension(L*W*H):

-

2400*1800*2100

-

Weight:

-

2700 KG

-

Product name:

-

Automatic Bottle Washing Filling Capping Machine

-

Function:

-

Washing Filling Capping

-

Bottle type:

-

PET Plastic Bottle

-

Suitable for:

-

Water Filling Line

-

Material:

-

SUS304 / 316

-

Capacity:

-

6000-8000BPH

-

Advantage:

-

Easy Operation High Efficiency

-

Control:

-

PLC+ Touch Screen

-

Certification:

-

CE Certificate

-

Air pressure:

-

0.4-0.6 MPa

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Water

-

Filling Accuracy:

-

±2mm

-

Voltage:

-

110-415V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

beierde

-

Dimension(L*W*H):

-

2400*1800*2100

-

Weight:

-

2700 KG

-

Product name:

-

Automatic Bottle Washing Filling Capping Machine

-

Function:

-

Washing Filling Capping

-

Bottle type:

-

PET Plastic Bottle

-

Suitable for:

-

Water Filling Line

-

Material:

-

SUS304 / 316

-

Capacity:

-

6000-8000BPH

-

Advantage:

-

Easy Operation High Efficiency

-

Control:

-

PLC+ Touch Screen

-

Certification:

-

CE Certificate

-

Air pressure:

-

0.4-0.6 MPa

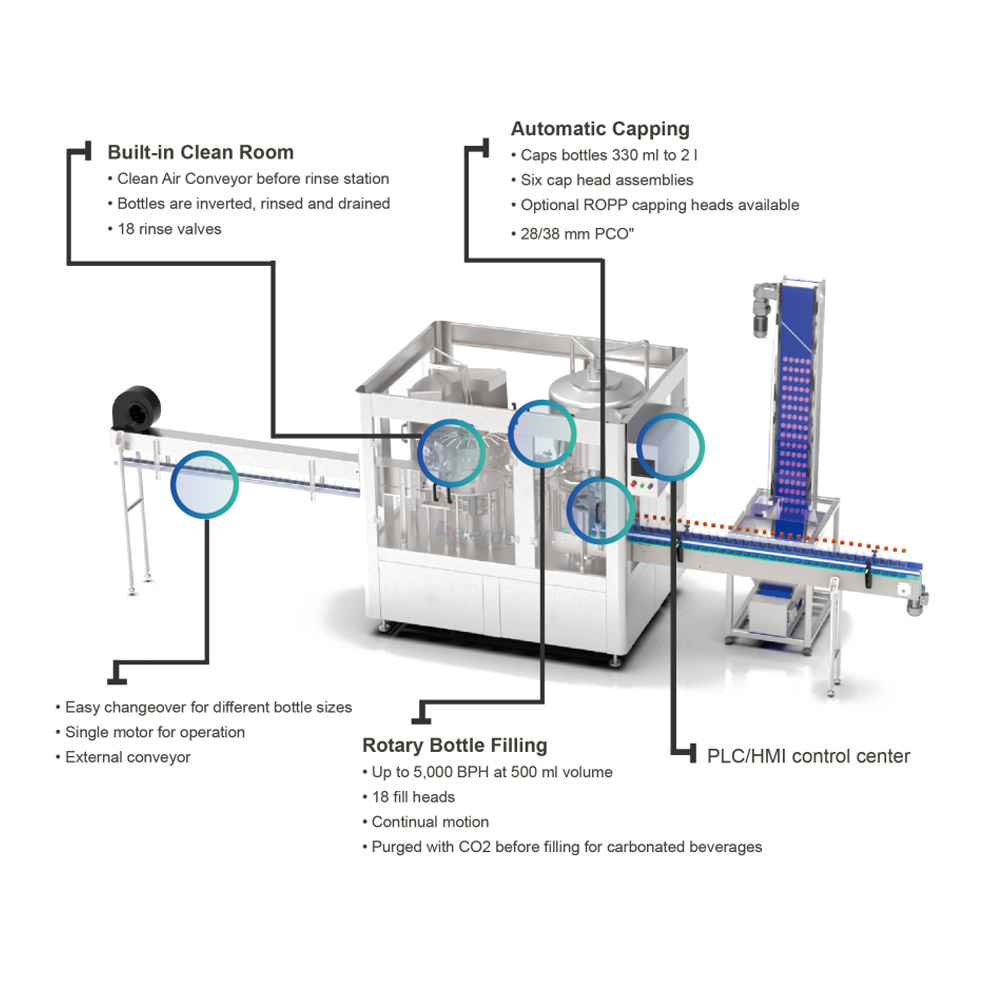

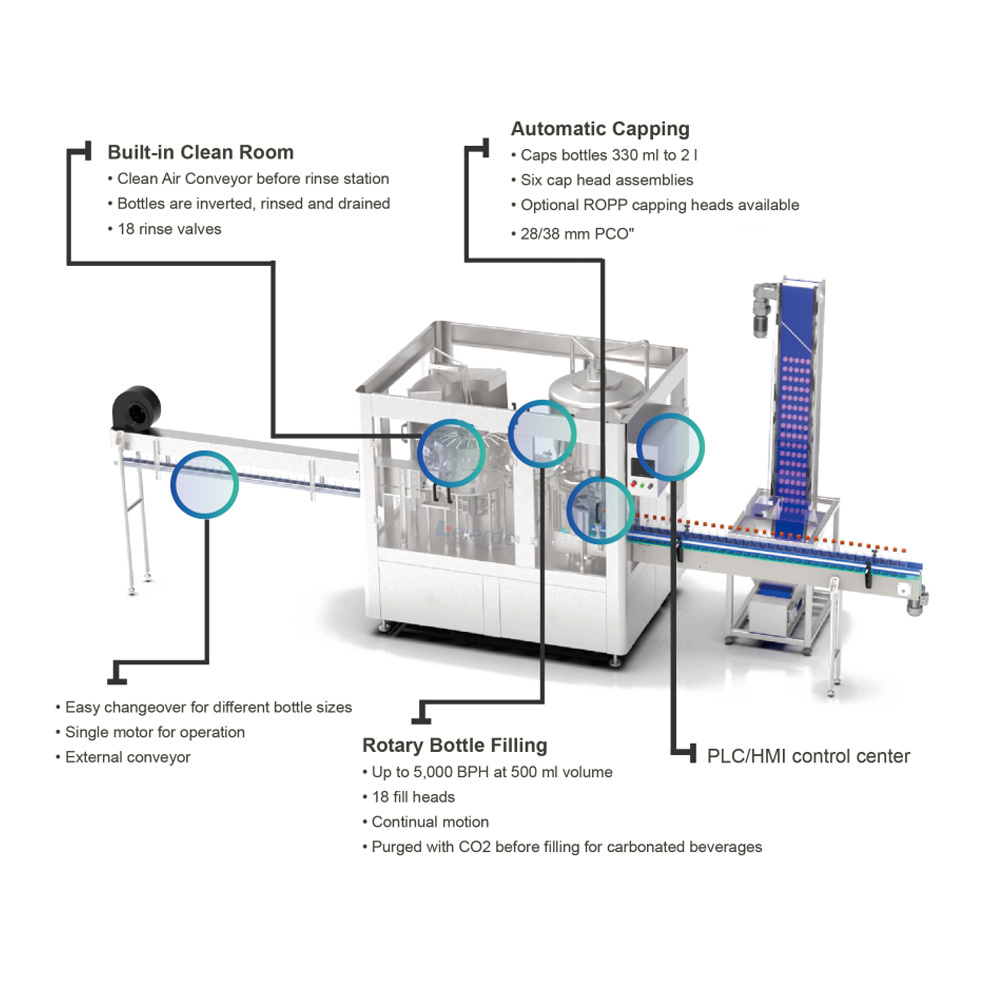

Water Filling Machine

The water filling machine is consisted of ringsing-filling-capping all together. CGF water filling machine adpots the suspension design. It allows the machine to fill different type of the bottles. It is normally used as drinking water filling machine. However, it can also be used for fill PET bottle with fruit juice and tea at high temperature by simply change the valve. It can be connected with our others machines to form the water filling machine and packaging machinery production line.

|

Model

|

CGF

8-8-4

|

CGF

14-12-5

|

CGF

18-18-6

|

CGF

24-24-8

|

CGF

32-32-10

|

CGF

40-40-12

|

CGF

50-50-12

|

CGF

60-60-15

|

|||||||

|

Capacity

0.5L/bottle/h |

3000

|

4000

|

8000

|

10000

|

14000

|

18000

|

24000

|

25000

|

|||||||

|

Suitable

bottle |

PET Bottle

|

|

|

|

|

|

|

|

|||||||

|

Bottle Diameter

|

50-115 mm

|

|

|

|

|

|

|

|

|||||||

|

Bottle

Height |

160-320 mm

|

|

|

|

|

|

|

|

|||||||

|

Compressed air pressure

|

0.3-0.7 Mpa

|

|

|

|

|

|

|

|

|||||||

|

Washing

mdeium |

Aseptic water

|

|

|

|

|

|

|

|

|||||||

|

Washing

water's pressure |

>0.06Mpa <=0.2Mpa

|

|

|

|

|

|

|

|

|||||||

|

Total power

|

2.5

|

3

|

3.5

|

4

|

5

|

6.2

|

8

|

10

|

|||||||

|

Weight<kg>

|

2500

|

3000

|

4500

|

5000

|

7500

|

8500

|

9000

|

9500

|

|||||||

Equipment structure:

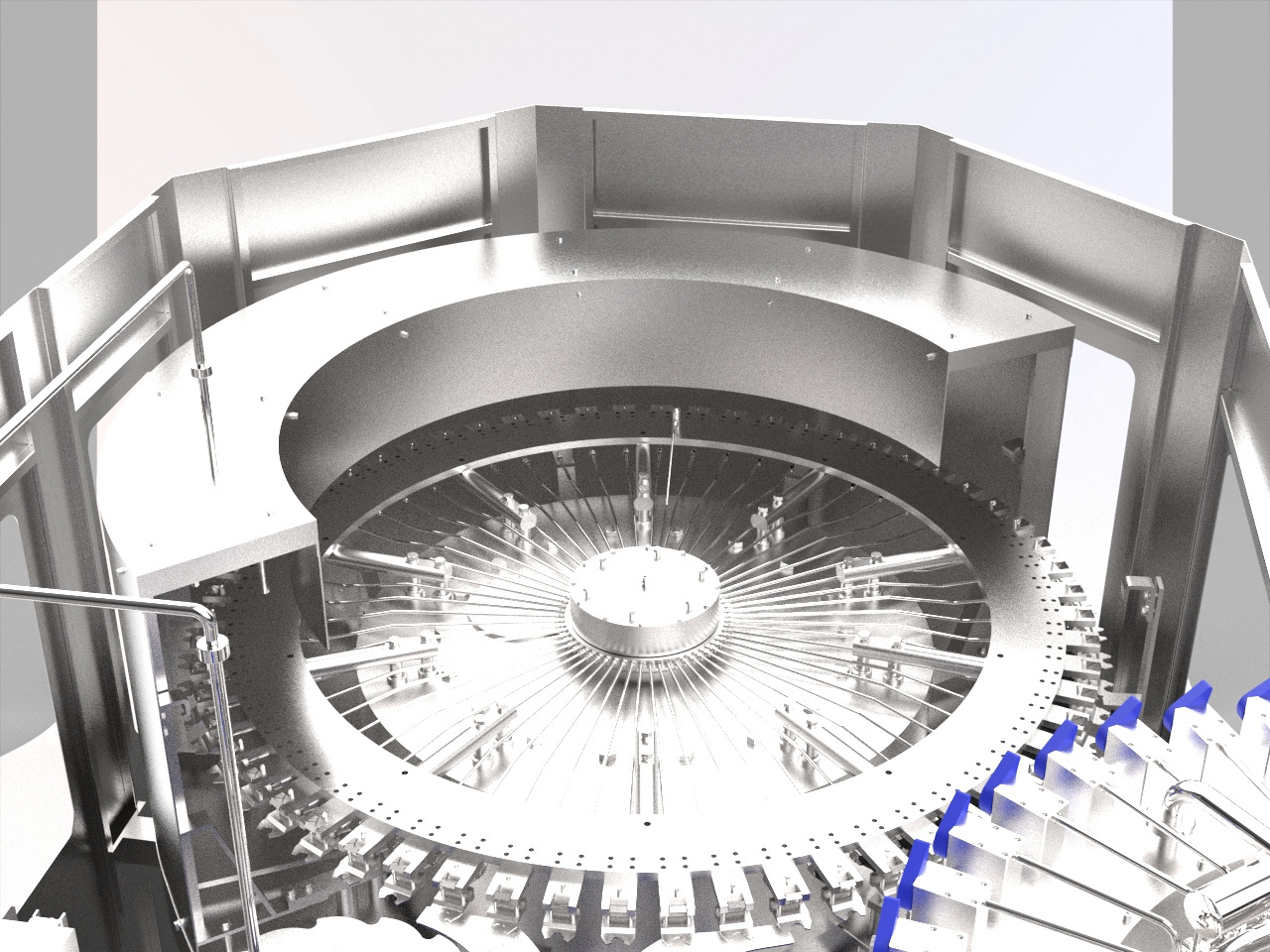

1. Rinsing system: Combined with rotary tray with clamp, water distributing tray, water tank and rinsing pump.

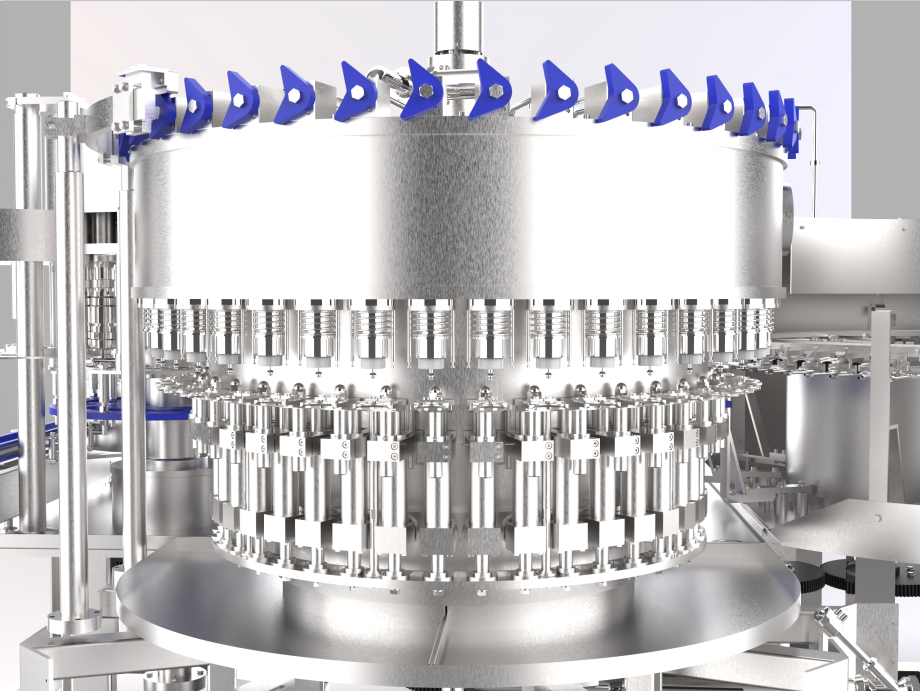

2. Filling system: Combined with hydraulic, filling valve, controlling ring, and elevator-cylinder.

3. Capping system:Combined with capper, cap sorter and cap falling track.

4. Driving system: Combined with main motor and gears.

5. Bottle transmitting system: Combined with air conveyor, steel starwheels and neck supporting carrier plates.

6. Electrical controlling system: this part is frequency inverted, PLC controlled and touch screen operated.

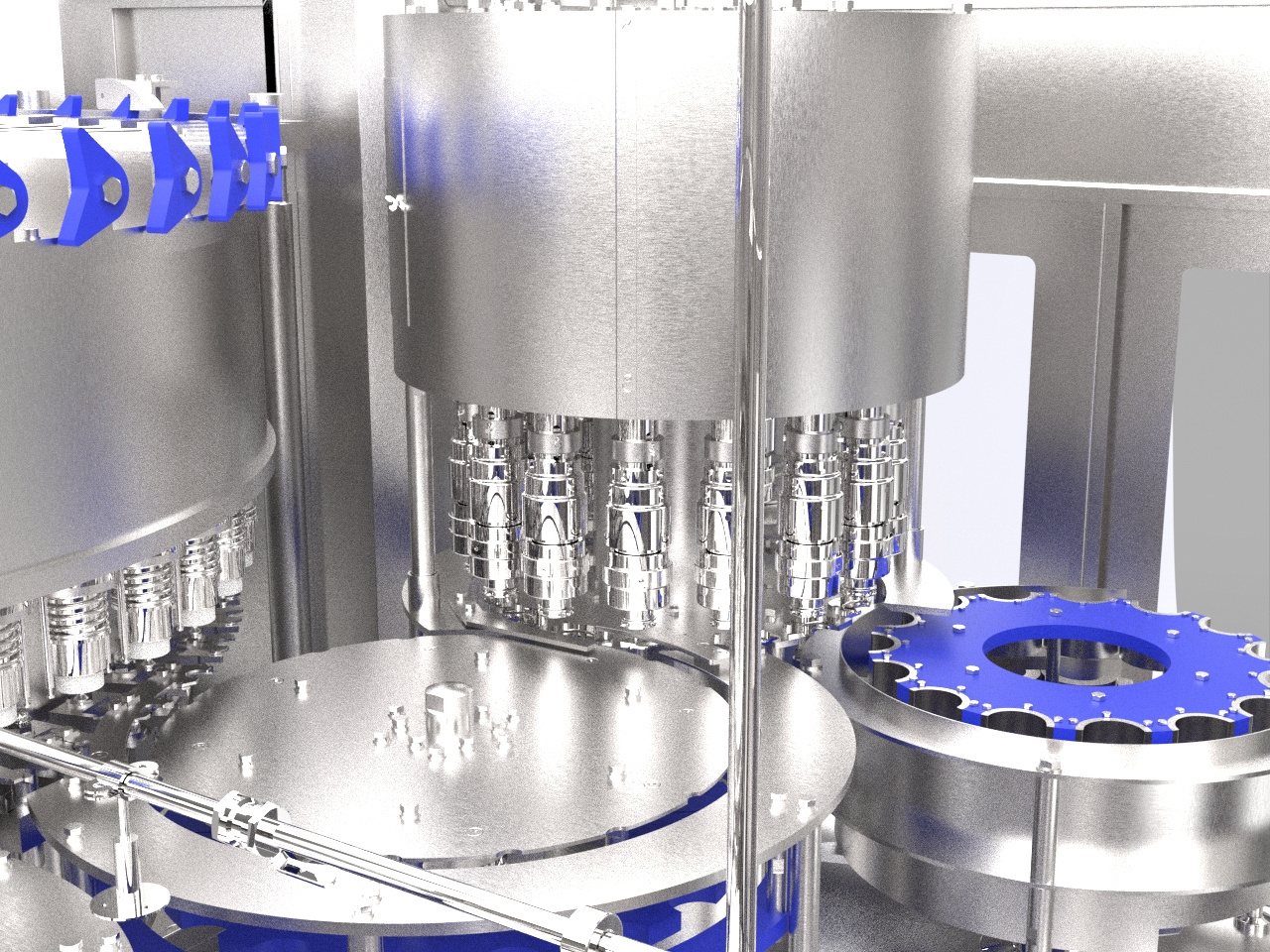

Washing heads.

Filling heads.

<1> 304/316 Stainless steel high precision filling nozzle

<2> Filling volume adjustable in fine rank, same liquid level after filling

<3> All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

<4> 304/316 stainless steel filling pump

Capping heads.

<1> Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

<2> All 304/316 stainless steel construction

<3> No bottle no capping

<4> Automatic stop when lack of bottle

RO water treatment system.

.Stainless steel high pressure film shell

•All kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system

•Online type pressure auto self-protection device

•Online type electricity indicator (with stable compensation)

•System safe protecting and alarm system

Blow molding system

Full automatic blow molding machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

1. With highe quality beam & photoelectric conversion, the marking quality and precision is more finer.

2. Small Size wtih Air cooling, no water chiller.

3.Easy to adjust focus.

4.low operation cost (Low power consumption).

5.Maintenance free without routine replacement of consumables.

6.Easy to use by unskilled operator.

Automatic Sleeve label machine

It adopts double driving structure which is a new and advanced driving device for the thermal shrink sleeve machine, that is, four-wheel driving, self-centering and balanced pressure of four wheels. It can achieve the good effect of transmission of labels smoothly, stably and rapidly.

PE film packaging machine

It adopts the photoelectric sensor to detect online, gather signals which are controlled by PLC, and adopts piston as executable element, to realize product conveying, combination, film wrapping, cutting, heat& shrink, cool and finally get the finished product.

Q2: Why is your prices higher than others?

A2: We offer high-end machines in our business. Welcome to our factory to have a visit. And you will see the difference.

Q3: What is your delivery time?

A3: Normally 30-60 working days depends one machines, water machines are faster, carbonated drink machines are slower.

Q4: How to install my machines when it arrives? How much the cost?

A4: We will send our engineers to your factory to install the machines and train your staff how to operate the machines If

needed.Or you can arrange engineers to study in our factory. You are responsible for air tickets, accommodation and our engineer wage USD100/day/person.

Q5: How long time for installation?

A5: Subject to machines and the situation in your factory. If everything is ready, it will take about 10 days to 25 days.

Q6: How about the spare parts?

A6: We will send one year enough easy broken spare parts together with the machines for free, we suggest you buy more units to save international courier such as DHL, it is really costly.

Q7: What is your guarantee?

A7: We have one year guarantee and life-long technical support. Our service also including machine maintainance .

Q8: What is your payment term?

A8: 30%T/T in advance as down payment, rest should be paid before shipping. L/C is supported also.