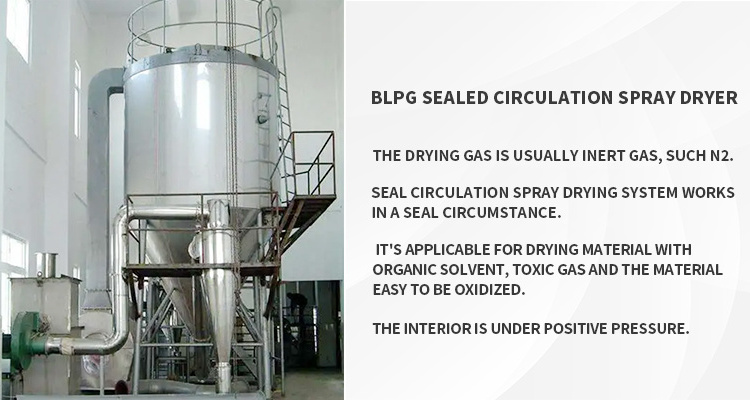

Seal circulation spray drying system works in a seal circumstance. The drying gas is usually inert gas, such N2. It's applicable for drying material with organic solvent, toxic gas and the material easy to be oxidized. Adopt inert gas as circulation gas, so to protect the material to be dried. The inert gas circulates after dehumidification process. N2 is heated and then enters into drying tower. Liquid material is conveyed to centrifugal nozzle by screw pump, and then it's atomized into the liquid mist by the atomizer, the heat transferring process is finished in the drying tower. The dry product is discharged at the bottom of tower; the evaporated organic solvent is sucked by the vacuum generated by the fan. Power or solid material will be separated in the cyclone and sprinkling tower. The saturated organic gas is drained out after it's condensed in the condenser. The gas not condensed recycles in the system after it's heated continuously. Ordinary normal centrifugal spray drying process is realized by air conveying and exhausting process. This is the obvious difference between explosion proof type sealed circulation centrifugal spray dryer and ordinary centrifugal spray dryer. The drying media in drying system is N2; the interior is under positive pressure. To keep positive pressure stable, the pressure transmitter controls the inlet amount of N2 automatically.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50HZ/3P

-

Power:

-

Accroding to model

-

Dimension(L*W*H):

-

Based on different model

-

Weight (KG):

-

2000

-

Marketing Type:

-

New Product 2023

-

After Warranty Service::

-

Online support

-

Applicable Industries::

-

Manufacturing Plant, Food & Beverage Factory

-

Application::

-

Chemicals Processing, Food Processing

-

Certification:

-

CE, IS014001, ISO9001

-

Core Components::

-

Bearing, Pump, Gear, Motor, Gearbox, PLC, Engine, Pressure vessel

-

Key Selling Points::

-

High Productivity

-

Heating source:

-

Electricity /Steam

-

Keywords:

-

BLPG Closed Cycle Spray Dryer

-

Usage:

-

Reduce Material's Moisture

Quick Details

-

Type:

-

Spray Drying Equipment

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BZ

-

Voltage:

-

380V/50HZ/3P

-

Power:

-

Accroding to model

-

Dimension(L*W*H):

-

Based on different model

-

Weight (KG):

-

2000

-

Marketing Type:

-

New Product 2023

-

After Warranty Service::

-

Online support

-

Applicable Industries::

-

Manufacturing Plant, Food & Beverage Factory

-

Application::

-

Chemicals Processing, Food Processing

-

Certification:

-

CE, IS014001, ISO9001

-

Core Components::

-

Bearing, Pump, Gear, Motor, Gearbox, PLC, Engine, Pressure vessel

-

Key Selling Points::

-

High Productivity

-

Heating source:

-

Electricity /Steam

-

Keywords:

-

BLPG Closed Cycle Spray Dryer

-

Usage:

-

Reduce Material's Moisture

Products Description

Description of BLPG

nano spray dryer pilot pressure nozzle spray dryer chamber

Why Choose Us

Our Advantages

1.Engineers available to service machinery overseas (All counties).

2. Overseas service center available (some countries).

3. Overseas third-party support available (some countries).

4. Our engineer have above 15 years professional experience in drying industry engaged in design, mechanical drawing, electrical automation edits etc.

5. We have rich project management experience and advanced site construction technology; we obtained good performance and well-known reputation.

6. We can show you the best price and high-quality machine.

7. We can show you the best price for our old customers, all new customers we will give 5% discount for the first time.

Applicable Scenarios

Product Parameters

|

Dried powder collecting

|

≥95%

|

|

Product Residual Solvent

|

≤2%

|

|

Oxygen contents

|

≤500 PPM

|

|

Explosion-proof of electric components

|

EXDIIBT4

|

|

System condition

|

Positive pressure

|

Process Flow Diagram

Various Specifications Available

Closed-circuit type/

Sealed circulation spray type

According to different customer requirements, according to the customer's material characteristics, there are a variety of specifications and models of spray. Please contact customer service for specific information.

Nitrogen flushing type

According to different customer requirements, according to the customer's material characteristics, there are a variety of specifications and models of spray. Please contact customer service for specific information.

Stainless steel material

According to different customer requirements and material characteristics, the equipment can be made of stainless steel, such as 304, 316, and 2205. Please contact customer service for specific information.

Carbon steel material

According to different customer requirements and material characteristics, the equipment can be made of carbon steel, such as A3 and Q235. Please contact customer service for specific information.

Intelligent PLC control

According to different customer requirements, intelligent PLC control is optional for the electronic control of the equipment. Please contact customer service for specific information.

Manual button control

According to different customer requirements, the electronic control of the equipment has button control options. Please contact customer service for specific information.

Hot Searches