- Product Details

- {{item.text}}

Quick Details

-

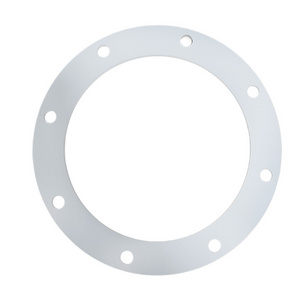

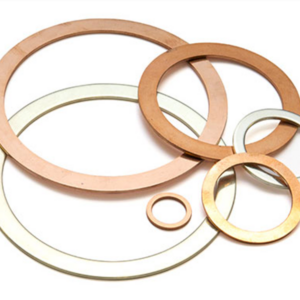

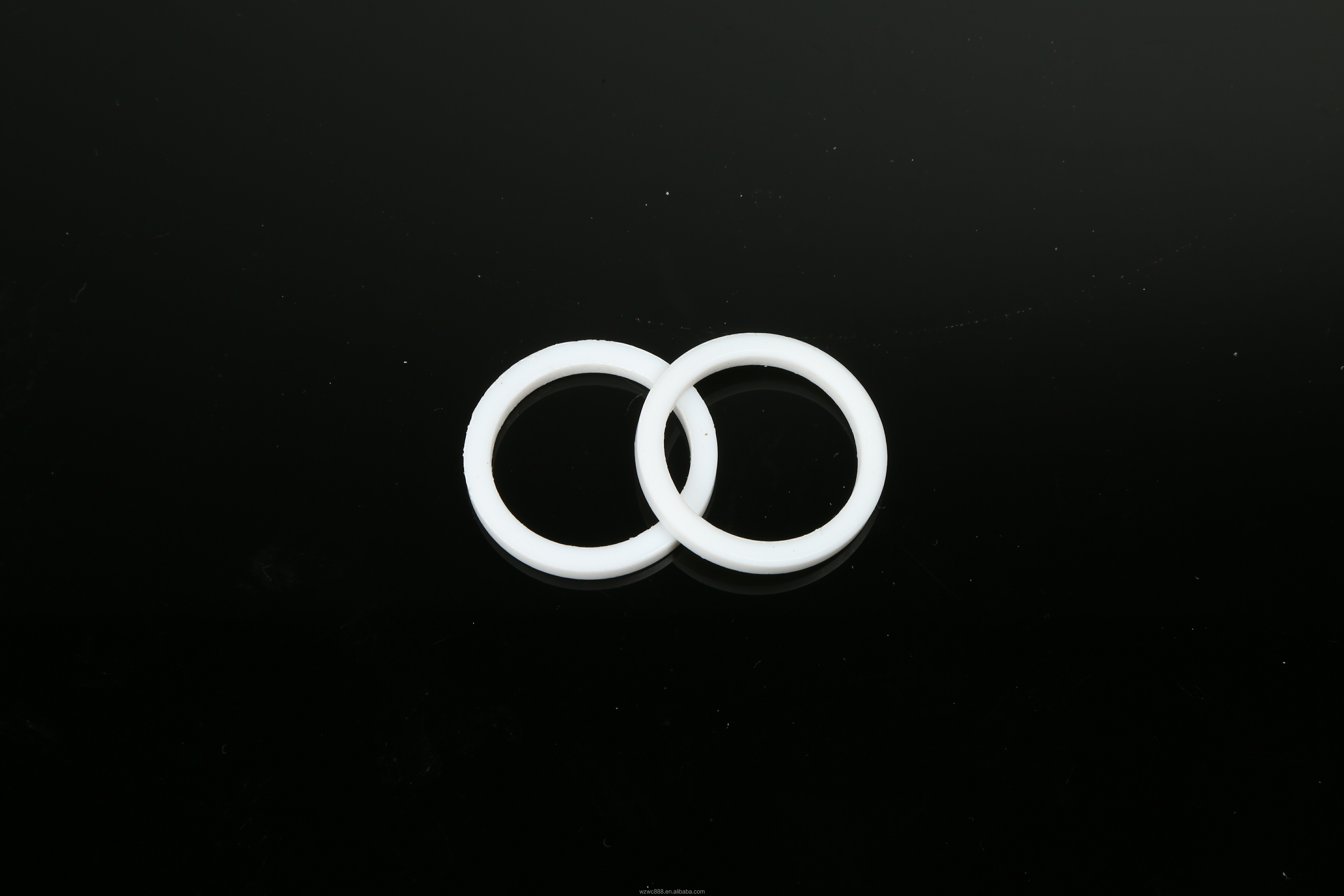

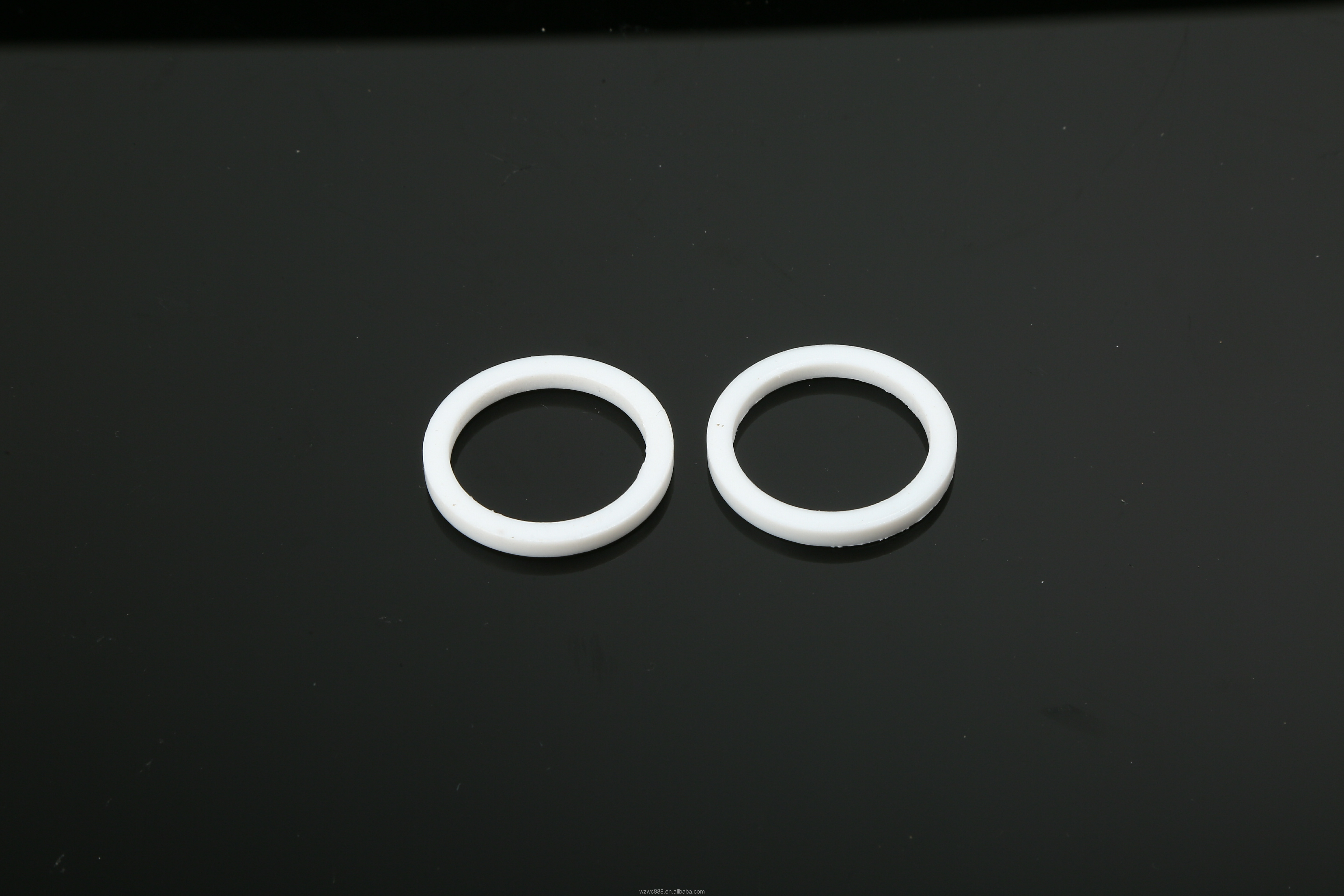

Product name:

-

ptfe gasket

-

Material:

-

100% Virgin ptfe

-

Temperature:

-

-180~260

-

Color:

-

white

-

Usage:

-

Sealing Usage

-

MOQ:

-

1000pcs

-

Lead Time:

-

7~15 Days

-

Size:

-

Customized

-

Application:

-

Mechanical Seals

-

Standard or Nonstandard:

-

Nonstandard

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

AOHONG

-

Model Number:

-

HSAH10

-

Product name:

-

ptfe gasket

-

Material:

-

100% Virgin ptfe

-

Temperature:

-

-180~260

-

Color:

-

white

-

Usage:

-

Sealing Usage

-

MOQ:

-

1000pcs

-

Lead Time:

-

7~15 Days

-

Size:

-

Customized

-

Application:

-

Mechanical Seals

-

Standard or Nonstandard:

-

Nonstandard

customized service:

Hello, this is Longwan Wenchong Fluoroplastics Factory for direct sales. We are not a supplier and have over 18 years of experience in PTFE production. You can rest assured of the quality of our products. We have many standard parts, and you can directly quote and place an order. Of course, there will be a discount for more orders. There are still many non-standard products, and we need you to provide us with the size and quantity of the products. We will provide you with a quotation. Or provide us with drawings

Our product catalog aims to provide you with more information about our products and services to help you make wiser purchasing decisions. If you have any questions about our products or services, please feel free to contact us at any time.

Thank you!

Good luck, [Ax]

performance

| name | introduce | characteristic |

| PTFE Material |

Polytetrafluoroethylene is non-toxic under normal conditions, but when the temperature of polytetrafluoroethylene cooking utensils reaches 500 ℉ (260 ℃), they will begin to deteriorate and decompose above 660 ℉ (350 ℃). |

Corrosion resistance:

capable of withstanding all strong acids (including fluoroantimonic acid, aqua regia), strong bases, strong oxidants, reducing agents, and various organic solvents except for molten alkali metals, fluorinated media, and molten strong bases.

Insulation: unaffected by environment and frequency, with a resistivity of up to 1018 ohms · cm, low dielectric loss, and high breakdown voltage. High and low temperature resistance: It has little effect on temperature and a wide temperature range, and can be used at temperatures of -190~260 ℃. Self lubrication: With the smallest friction coefficient among plastics, it is an ideal oil-free lubricating material. Surface non adhesion: Known solid materials cannot adhere to the surface and are the solid materials with the smallest surface energy. Atmospheric aging resistance, radiation resistance, and low permeability: The surface and properties remain unchanged after long-term exposure to the atmosphere. Non flammability: The oxygen limiting index is below 90. |

| PCTFE Material | It decomposes in water and is prone to polymerization. |

Critical temperature:

105.3 ° C

Critical pressure: 4.063 MPa Highly toxic. It is prone to spoilage in the air and produces phosgene. [Source Request] LD50: 268 mg/kg (rat oral) |

| PPL Material |

Used to make oil-free lubricating sealing rings, fillers, piston rings, etc;

|

High temperature resistance:

When burning "polystyrene" powder in a high-temperature furnace, it begins to decompose at 520 ℃ without any melting point. When heated for a long time at 450 ℃, there is slight weight loss when burned. It is an engineering plastic that is used for a long time below 400 ℃.

Radiation resistance: Under the irradiation of a cobalt source (Co60), it can withstand 9 * 10 6 lats without changing its performance. Chemical corrosion resistance and solvent resistance: So far, no solvent has been found in the world that can dissolve polystyrene, and strong acids and bases such as hydrofluoric acid sulfate cannot corrode it. Electrical performance: The volume resistivity is 1015 ohms centimeters, and under different polymerization conditions, it can also become an organic semiconductor. The volume resistivity is 1017 ohms centimeters. Self lubrication performance: It has good self-lubricating performance, greatly superior to molybdenum disulfide, graphite, or other filled polystyrene tetrafluoroethylene products. |

| Polyphenyl ester Material | Polyphenyl ester, English name: polyphenyl ester, abbreviated as POB or PHB, foreign trade name: EkonoI |

polystyrene ester filled PTFE materials are the most commonly used. This blend material retains the characteristics of heat resistance, self-lubricating, insulation, and solvent resistance of both materials, and can complement each other in terms of performance, overcoming the shortcomings of PTFE such as non wear resistance, easy creep, poor thermal conductivity, and brittleness of polystyrene ester |

| PEEK Material | PEEK is a semi crystalline thermoplastic polymer with excellent mechanical properties and chemical stability. |

Heat resistance:

PEEK is a high-temperature resistant thermoplastic resin with a melting point of 334 ℃ and a long-term use temperature of 250 ℃. Short term working temperature of 300 ℃.

Flexibility: Ranked among the top in high-temperature resistant resins. Flame retardancy: UL94V-0 level self ignition, low smoke emission. Drug resistance: only soluble in concentrated sulfuric acid Processing formability: Good fluidity, convenient for secondary processing |

A: We are not a trading company, we are manufacturers selling directly