- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

IDL-Nylon-036

-

Color:

-

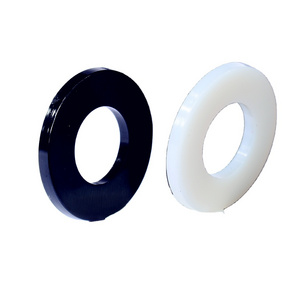

Beige, natural, black,white

-

Specification:

-

OEM/ODM

-

Weight:

-

0.01g~500g

-

Processing:

-

CNC machining or molding injection

-

Tolerance:

-

+-0.05mm

-

Temperature Resistance:

-

-40~120℃

-

MOQ:

-

1000pcs

-

Lead time:

-

3-7days

-

Packaging:

-

Inner pp box, outside paper box

-

Sample:

-

to be negotiated

Quick Details

-

Processing Service:

-

Moulding

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

IDEAL

-

Model Number:

-

IDL-Nylon-036

-

Color:

-

Beige, natural, black,white

-

Specification:

-

OEM/ODM

-

Weight:

-

0.01g~500g

-

Processing:

-

CNC machining or molding injection

-

Tolerance:

-

+-0.05mm

-

Temperature Resistance:

-

-40~120℃

-

MOQ:

-

1000pcs

-

Lead time:

-

3-7days

-

Packaging:

-

Inner pp box, outside paper box

-

Sample:

-

to be negotiated

PA (Polyamide),commonly known as Nylon,are elements on the main chain amide group containing duplicate(NHCO) general term for the thermoplastic resin.It is a translucent or white crystalline resin and his molecular weight is generally 1.5-3 million.Nylong has high mechanical strength,high softening point,heat resistance,low coefficient of friction,wear-resisant,self-lubricating,shock-absorbing,oil resistance,weak acid,alkail and general solvents;good electric insulation,self-extinguishing nature,non-toxic,odorless,weather resistance and so on.Nylon and glass fiber affinity is very good,so easy to enhance.However, the dyeing properties of Nylon bad, it is not easy coloring,The absorbent nylon influence dimensional stability and electrical perfermance,fiber-reinforced resin to reduce water absorbtion,so that it can be at high temperature,high humidity to work.For the burning of nylon UL94-V2 class,oxygen index for the 24-28.Decompositioon temperature of the nylon>299°C,at 449°C-499°C spontaneous combustion occurs.The mobility of nylon melt well,so product can be as small as wall thickness 1mm.

| Item | Test condition | Test standard | Unit | PA-66 | PA-6 | PA-610 | PA-612 | PA-1010 | PA-11 | PA-12 |

| Density | 23°C | ISO1183 | g/cm³ | 1.14 | 1.14 | 1.09 | 1.07 | 1.05 | 1.04 | 1.02 |

| Melting point | 23°C | DSC | °C | 260 | 225 | 213 | 210 | 200-210 | 187 | 178 |

| Mold shrinkage | ISO294-4 | % | 0.8-1.5 | 0.6-1.6 | 1.2 | 1.1 | 1.0-1.5 | 1.2 | 0.3-1,5 | |

| Tensile strength | 23°C | ISO527-1,2 | MPa | 80 | 75 | 60 | 62 | 55 | 55 | 50 |

| Tensile modulus | 23°C | ISO-178 | GPA | 2.9 | 2.5 | 2.0 | 2.0 | 1.6 | 1.3 | 1.3 |

| Elongation at break | 23°C | ISO527-1,2 | % | 60 | 50 | 200 | 200 | 250 | 300 | 300 |

| Flexural modulus | 23°C | ISO-178 | GPa | 3.0 | 2.6 | 2.2 | 2.0 | 1.3 | 1.0 | 1.4 |

| Impact strength(notch) | 23°C | ISO-179 | kJ/m2 | 4 | 5.5 | 5.5 | 5.4 | 4.0-5.0 | 4.0 | 5.0 |

| Rockwell hardness | 23°C | D785 | 118 | 114 | 116 | 114 | 95 | 108 | 106 |

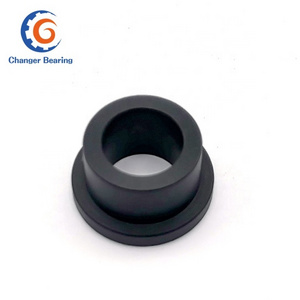

Item: nylon spacer(delrin spacer,ABS spacer)

Material: Nylon, Nylon 6. Nylon 66. Oil Nylon.MC Nylon, or Nylon Modification material (PA10,PA12....)

Color: white, black, or as per requirement

Size: according to custom's requirement, drawing will be highly appreciated.

Weight: from 0.01gram to 10kgs

Tolerence: +/-0.04-0.1mm, according to requriement

Processing: precision CNC machine or injection molding.

Properties:

1. Working temperature: -40-160 degree (GF or CF reinforced)

2. Excellent Wearproof/mechanical properties

3. High-strength, self-lubrication. good toughness

4. Easy to be colored (white, yellow,blue, red, green....)

Industry Application:

Gear/worm/cam

bearing

wheel/pulley/sheave/collar

sleeve/screws/nuts

washer/bushing

High pressure pipeline

storage containers

Oil Tank

If you have any inquiry to our company, please feel free to contact with us. Thank you !