- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Carton, FRP/Carbon Steel/Stainless Steel

-

Weight:

-

20kg

-

Size:

-

40*35*35cm

-

Weight (KG):

-

14 kg

-

Product name:

-

Expansion Tank

-

Type:

-

Horizontal, Vertical

-

Volume:

-

24L-50000L

-

Diaphragm:

-

EPDM, BUTYL

-

Working Temperature:

-

-10 - 100 ℃

-

Tank Colour:

-

Blue,Red

-

Working Pressure:

-

8Bar 10Bar 16Bar 25Bar

-

Per-Charge Pressure:

-

2 BAR

-

Certification:

-

CE ISO

Quick Details

-

Core Components:

-

Expansion Tank

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

HatChee

-

Material:

-

Carton, FRP/Carbon Steel/Stainless Steel

-

Weight:

-

20kg

-

Size:

-

40*35*35cm

-

Weight (KG):

-

14 kg

-

Product name:

-

Expansion Tank

-

Type:

-

Horizontal, Vertical

-

Volume:

-

24L-50000L

-

Diaphragm:

-

EPDM, BUTYL

-

Working Temperature:

-

-10 - 100 ℃

-

Tank Colour:

-

Blue,Red

-

Working Pressure:

-

8Bar 10Bar 16Bar 25Bar

-

Per-Charge Pressure:

-

2 BAR

-

Certification:

-

CE ISO

Fiberglass Bladder Water Pressure Tanks

Fiberglass bladder water pressure tanks are the ideal choice for new and replacement residential installations and pressure boosting applications. They offer features and benefits steel tanks just can’t match. From their corrosion-proof composite construction to their lighter weight, easier maintenance and less expensive installation. Fiberglass bladder water pressure tanks are the preferred choice of professionals. Especially when the following advantages are added to the mix:

• Replaceable Air Cell -- for easier field servicing.

• Greater Drawdown than Comparably-Sized Steel Tanks -- for greater efficiency.

• Extended Labor Warranty Option (by homeowner).

• Won’t Rust in Corrosive Environments -- particularly important in agricultural and livestock applications, and coastal regions.

• Quicker and Less Costly to Install -- usually requiring only one person and fewer man-hours.

• Wider Pressure Setting Differential -- for greater flexibility.

Features and Benefits

• Corrosion-proof composite construction

• One piece, seamless inner shell molded of premium high-density polyethylene

• Durable blow-molded interior air cell is fully replaceable and constructed of heavy-gauge engineered polymer

• Bottom inlet/outlet assembly is custom molded of high-impact PVC

• Sturdy molded polymeric base is corrosion and impact proof

• Outer shell is a composite of continuous fiberglass strands sealed with high-grade epoxy resin

• Replaceable Air Cell

• Greater drawdown than comparably sized steel tanks for greater efficiency

• Light Weight – minimizes labor cost; no need for heavy equipment

Performance Data

|

Model |

Connection |

Nominal Volume |

Dimensions (mm) |

Gross Weight

|

||||

|

Liters |

Gallons |

A |

B |

C |

D |

|||

|

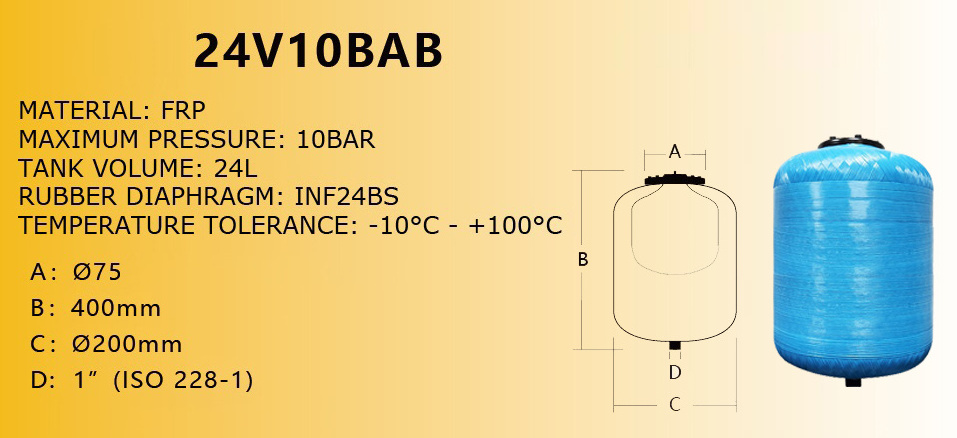

24V10BAB |

1" |

24 |

6 |

75 |

400 |

200 |

1" |

4 |

|

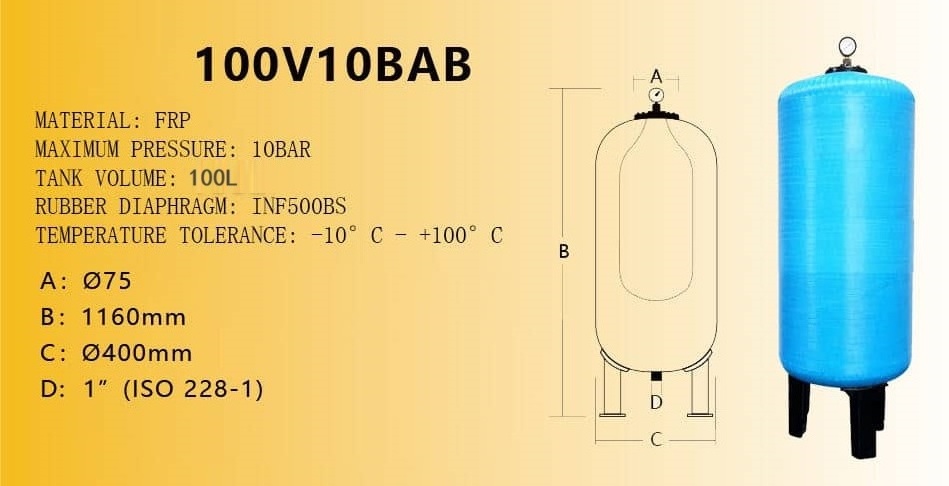

100V10BAB |

1" |

100 |

26 |

75 |

1160 |

400 |

1" |

12 |

|

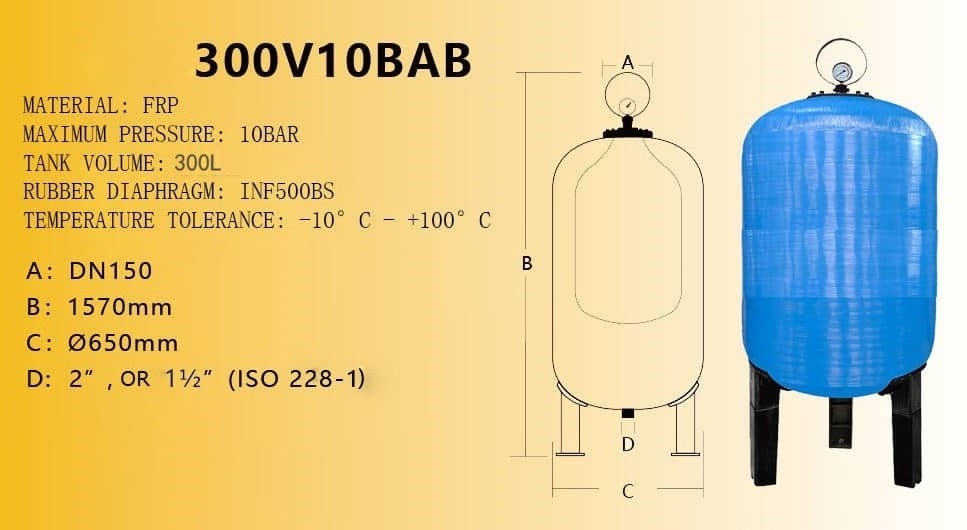

300V10BAB |

1.5"/2" |

300 |

80 |

DN150 |

1570 |

650 |

1.5"/2" |

28 |

|

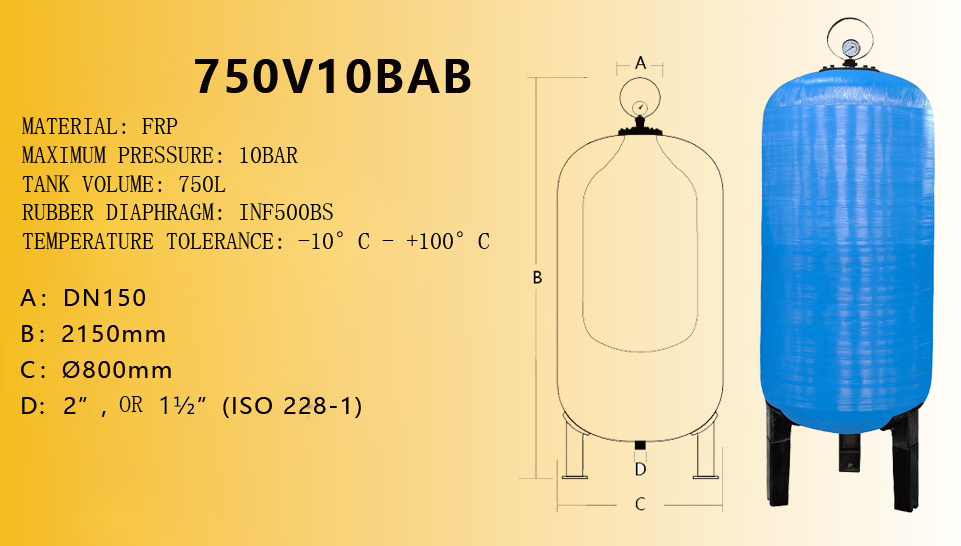

750V10BAB |

1.5"/2" |

750 |

200 |

DN150 |

2150 |

800 |

1.5"/2" |

90 |

|

300V10NAR |

1.5"/2" |

300 |

80 |

DN150 |

1570 |

650 |

1.5"/2" |

28 |

|

750V10NAR |

1.5"/2" |

750 |

200 |

DN150 |

2150 |

800 |

1.5"/2" |

90 |

Carbon Steel and Stainless Steel Expansion Tank s

Expansion Tanks, also known as expansion tanks, can be found in most domestic pressurised heating systems. If you have a combi boiler, you will have an expansion vessel. This vessel contains air and water from the central heating system, and its purpose is to maintain the right level of pressure in the system.

There are various expansion tank designs, but the most common among modern boiler designs is the bladder type system. This design consists of a cylinder or disc which is split into two parts by a thin rubber sheet known as a ‘diaphragm’. One side is filled with water from the central heating system, while the other is filled with nitrogen. An expansion vessel also has an air valve that allows for the system to be depressurised and repressurised over time.

Diaphragm Pressure Tank Product Overview

The diaphragm type pressure tank adopts standard or non-standard design, standardized welding technology, and has air supply and deflation devices. It is divided into two types: diaphragm type and normal type. The surface is coated with advanced spray technology and has high corrosion resistance. Widely used in pneumatic water supply equipment and pressurized regulated water supply equipment. The diaphragm type pressure tank is an energy storage device composed of a steel outer casing and a rubber diaphragm inner tank. The rubber diaphragm completely separates the water chamber and the air chamber, and is sealed when the pressurized water is filled into the inner tank of the diaphragm type pressure tank. The air in the tank is compressed. According to Boyle's law of gas, the volume of the gas is compressed, the volume is reduced, the pressure is increased to store energy, and the expansion of the compressed gas can push the water in the rubber diaphragm out of the tank.

Diaphragm pressure tank product features

1. Wide range of withstand voltage;

2, strong corrosion resistance;

3. Easy to use and maintain;

4. Safe and reliable operation.

5. The internal diaphragm structure of the tank ensures that the water does not come into contact with the tank wall, so there is no rust inside the tank wall, no condensation on the outside, and the service life is greatly prolonged.

6, the rubber diaphragm can relax more than 200,000 times, can be used for a long time after inflation.

7, can effectively smooth the pressure fluctuations in the water system, reducing the start and stop frequency of the pump.

8. The diaphragm is a food grade natural rubber diaphragm that can be used in drinking water systems.

Diaphragm pressure tank technical parameters

The diameter is 600~2500mm;

Pressure range 0~2.5Mpa;

The ambient temperature is 0~40 °C.

Materials of Construction:

Body : Carbon Steel and Stainless Steel

Bladder (Membrane): EPDM, BUTYL

Orientation:

Vertical

Horizontal

Working Pressure:

6 Bars

10 Bars

16 Bars

25 Bars

Diaphragm pressure tank adaptation range

Diaphragm pressure tanks are widely used in central air conditioning circulating water regulators, steamed water supply expansion systems, heating system circulating water hydration regulators, fire water supply system hydration regulators, frequency conversion water supply regulators, boiler hydration, pneumatic water supply and other occasions. The high working pressure of the diaphragm type pressure tank is 0.6mpa, 1.0mpa, 1.6 mpa, the fire water storage volume is more than 150L, 300L, 450L, and the regulated water volume is more than 50L. When used in the fire hydrant system, the water gun per flow is 2.5L. /S, 5L/S, the length of the water column is 7M, 10M, 13M; for the automatic water spray system, the flow rate of each nozzle is 1.0L/S, and the nozzle pressure is 0.1MPA. The equipment can keep the fire pressure of the fire water supply pipeline system at all times, and always use the pressure water tank to store 30 seconds of fire water; the equipment uses the operating pressure set by the pressure water tank to control the pump operating conditions and increase Voltage regulation function.

|

PH Value of slurry: 2.5-13

|

Slurry temperature ≤ 65ºC

|

X type frame,space saving

|

|

|

Large capacity

|

High head

|

High efficiency

|

|

|

Wear resistance

|

Corrosion resistance

|

Energy saving

|

|

|

Wide flow range

|

Stable performance

|

Heavy duty

|

|

|

Little noise

|

Low vibration

|

Long service life

|

|

|

Interchangeable parts

|

Reliable operation

|

High chrome alloy material

|

|

|

Oil lubrication

|

Clockwise from drive end

|

Intergrating mechanical seal

|

|