- Product Details

- {{item.text}}

Quick Details

-

Applicable material:

-

Aluminum Channelume

-

Function:

-

Auto Feeding+bending+slotting

-

Model:

-

AL160/AL200

-

Usage:

-

Advertising Industry

-

Voltage:

-

220V

-

Application:

-

Making 3D Sign Channel Letters

Quick Details

-

Place of Origin:

-

China

-

Weight (KG):

-

370

-

Product name:

-

Aluminum Letter Bender Machine

-

Applicable material:

-

Aluminum Channelume

-

Function:

-

Auto Feeding+bending+slotting

-

Model:

-

AL160/AL200

-

Usage:

-

Advertising Industry

-

Voltage:

-

220V

-

Application:

-

Making 3D Sign Channel Letters

|

Model

|

HH-AL130

|

HH-AL160

|

|

Slot Angle

|

45°-135°

|

45°-135°

|

|

Bending Radius

|

≥3mm

|

≥3mm

|

|

Material Width

|

≤130mm

|

≤160mm

|

|

Material Thickness

|

aluminum:0.3-16.mm/S.S:0.3-1.5mm

|

aluminum:0.3-16.mm/S.S:0.3-1.5mm

|

|

Machine Power

|

≤2000w

|

≤2000w

|

|

Working Air Pressure

|

0.4-0.8Mpa

|

0.4-0.8Mpa

|

Application:

The application range of the Channel Letter Bending Machine is generally in the advertising industry. When the advertising companyneeds to do the luminous characters for the shops,it needs to use the channel letter bending machine to make the production. The channel letter bending machine can process many materials aluminum profiles, aluminum strip ) and does not damage the material.The processing precision is high and the speed is fast. The material thickness and tool adjustments are all adjusted by software,more convenient and fast.

The application range of the Channel Letter Bending Machine is generally in the advertising industry. When the advertising companyneeds to do the luminous characters for the shops,it needs to use the channel letter bending machine to make the production. The channel letter bending machine can process many materials aluminum profiles, aluminum strip ) and does not damage the material.The processing precision is high and the speed is fast. The material thickness and tool adjustments are all adjusted by software,more convenient and fast.

Feeding:

1.The feeding roller diameter 45mm and install encoder, the precision and speed is similar as manipulator .

2.Install return material control device which ensure the returned material precision.

3. The guide roll diameter 60mm and ensure the material more straight when feeding.

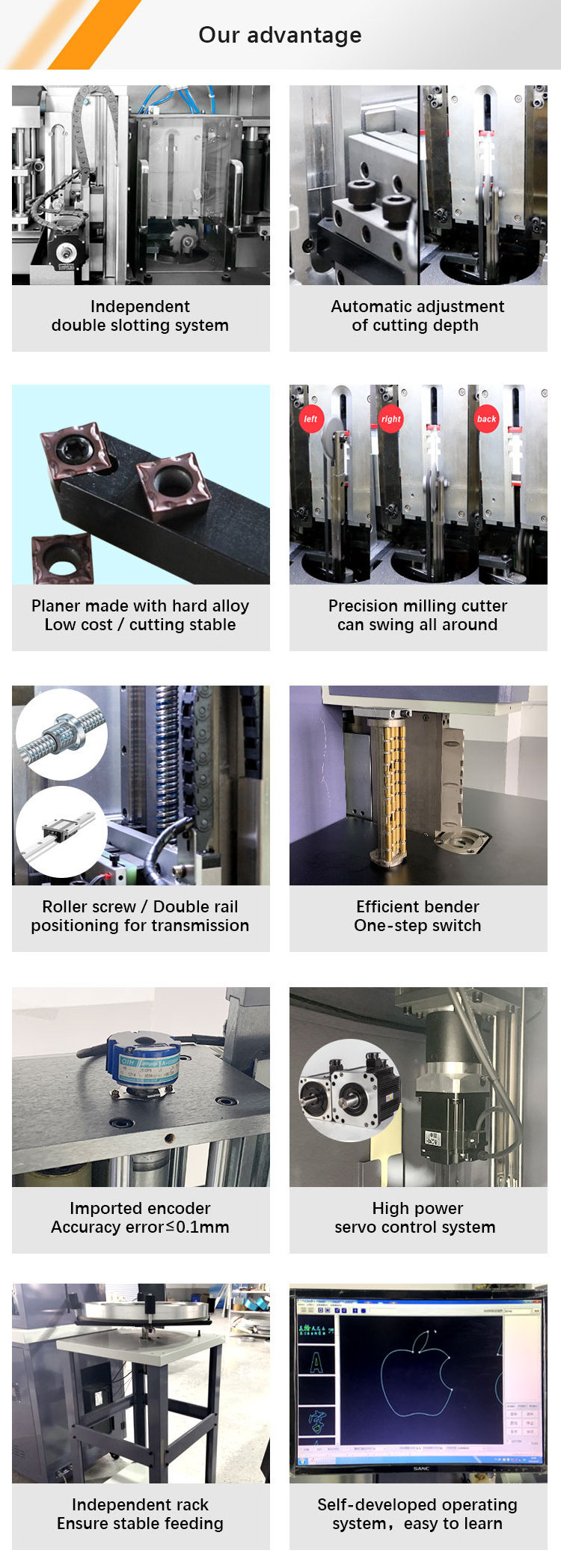

Aluminum notching

1.Aluminum cutting use 20mm Taiwan PDF guide rail ,the knife 75mm , guarantee the smooth cutting with fast rotating speed and small cutting angle.

2.Cutting mode use motor lifting control ,more stable ,not easy damage material and noise small.

3.Use four-column design ensure the cutting stable and effect.

Stainless steel notching:

1.Planer have current induction automatic knife adjustment, very easy finish cutting depth through software ,more precision than manual adjust.

2.Double Japan Fuji Servo motor and driver for cutting and bending , 20mm leading screw, more fast ,stable and high precision .One set bender can service 6sets laser welding working.

3.The Planner cutter use carbide blade, each blade have 8 sides ,every side can working about 7000 times ,the use cost is very lower and cutting effect is beautiful .

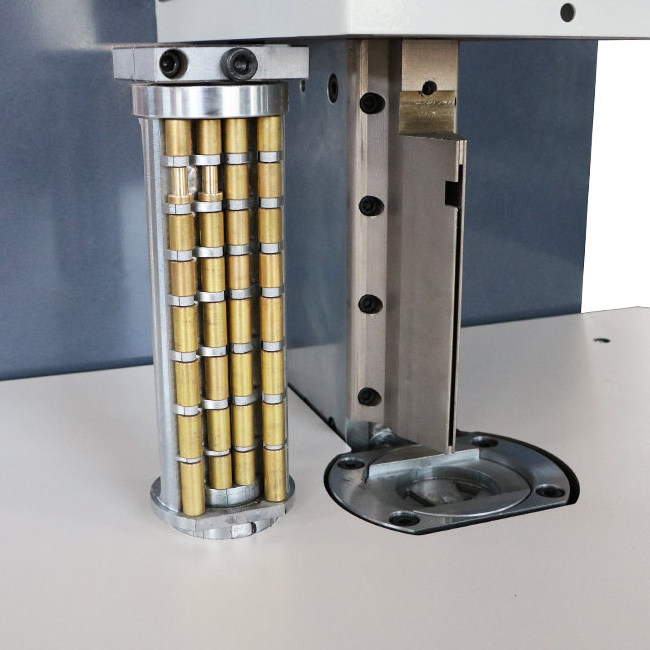

Bending

1. Use double arc bender design , lifting arc beating and squeezing, for the bender use one-button disassembly,usually one minutes can finish , improve the working efficiency .

2.At the consistency , the lifting arc beating is more better than fixed single axis arc beating ,finish the Stainless steel width can meet 13-16cm . But others only meet 8-10cm.

3.There is two groups grinding gear on arc bending parts ,ensure arc bending accuracy and reduce noise .

1.The feeding roller diameter 45mm and install encoder, the precision and speed is similar as manipulator .

2.Install return material control device which ensure the returned material precision.

3. The guide roll diameter 60mm and ensure the material more straight when feeding.

Aluminum notching

1.Aluminum cutting use 20mm Taiwan PDF guide rail ,the knife 75mm , guarantee the smooth cutting with fast rotating speed and small cutting angle.

2.Cutting mode use motor lifting control ,more stable ,not easy damage material and noise small.

3.Use four-column design ensure the cutting stable and effect.

Stainless steel notching:

1.Planer have current induction automatic knife adjustment, very easy finish cutting depth through software ,more precision than manual adjust.

2.Double Japan Fuji Servo motor and driver for cutting and bending , 20mm leading screw, more fast ,stable and high precision .One set bender can service 6sets laser welding working.

3.The Planner cutter use carbide blade, each blade have 8 sides ,every side can working about 7000 times ,the use cost is very lower and cutting effect is beautiful .

Bending

1. Use double arc bender design , lifting arc beating and squeezing, for the bender use one-button disassembly,usually one minutes can finish , improve the working efficiency .

2.At the consistency , the lifting arc beating is more better than fixed single axis arc beating ,finish the Stainless steel width can meet 13-16cm . But others only meet 8-10cm.

3.There is two groups grinding gear on arc bending parts ,ensure arc bending accuracy and reduce noise .

Whole Machine Feature:

1.Whole machine guarantee 2 years , the motor guarantee 3 years.

2. Processing material width:10-160mm, Thickness : Aluminum 0.3-1.5mm, Stainless steel 0.3-1.2mm,Suitable for most of Aluminum profile.

3.All machining parts be treated with hard chromium plating,which is wear-resistant and corrosion-resistant, especially suitable for coastal areas.

4.In the overall structure the working platform use 14mm whole plate deal with three times plain grinding finish ,the internal workpiece thickness 17mm,ensures the long-term working stability and accuracy .

5.The motor and driver use the transformer with voltage digital display device to replace switching power,monitor the voltage situation and remind customer to do the corresponding treatment when the voltage is unstable .

6.The software have Length closed-loop control system ,the length precision ≤0.1mm. Meantime Independent development software system , which can updated according customer need and more easy to use .

7.Whole machine weight meet 530kgs and more stable.

8.Install cutting protection device to prevent cutting debris from splashing.

1.Whole machine guarantee 2 years , the motor guarantee 3 years.

2. Processing material width:10-160mm, Thickness : Aluminum 0.3-1.5mm, Stainless steel 0.3-1.2mm,Suitable for most of Aluminum profile.

3.All machining parts be treated with hard chromium plating,which is wear-resistant and corrosion-resistant, especially suitable for coastal areas.

4.In the overall structure the working platform use 14mm whole plate deal with three times plain grinding finish ,the internal workpiece thickness 17mm,ensures the long-term working stability and accuracy .

5.The motor and driver use the transformer with voltage digital display device to replace switching power,monitor the voltage situation and remind customer to do the corresponding treatment when the voltage is unstable .

6.The software have Length closed-loop control system ,the length precision ≤0.1mm. Meantime Independent development software system , which can updated according customer need and more easy to use .

7.Whole machine weight meet 530kgs and more stable.

8.Install cutting protection device to prevent cutting debris from splashing.

WEIFANG NEW HH CORP

WEIFANG NEW HH are a Chinese supplier specializing in the export of advertising machinery and equipment. We mainly produce Letter Bending Machine, Acrylic Heat Bending Machine, etc. We also provide customers with CNC Router Machine, Co2 Laser Cutting Machine, aluminum coil and other advertising industry supporting products. Our customers It covers more than 100 countries in the world and has after-sales service in more than 30 countries. For advertising equipment, choose WEIFANG NEW HH!

1.What's the Payment terms?

There are 3 ways to pay money:

1). T/T, means international bank transfer, 30% deposit, we produce the machine for you, 70% before shipping. It's convenient and fast.

2). Alibaba Secure payment. Reliable and safe, Alibaba will charge a litter extra fee for the service.

3). Other kinds of payment we can consider if acceptable for us.

2.what's the warranty service?

12 months for all machines and 24 months for motors.

3.How to install and run the machine?

We will send the user's manual and the install video with the machine, you could learn by yourselves, we also provide remote machine training or overseas training services.

4.Do you have matching materials for sale?

Yes,we have all kinds of materials such as aluminum coil, stainless steel, galvanized iron, coppers etc. for sale.

5.How to choose a suitable machine?

You can tell us the working piece material, size, and the machine function request. We can

recommend the most suitable machine according to our experience.

1). T/T, means international bank transfer, 30% deposit, we produce the machine for you, 70% before shipping. It's convenient and fast.

2). Alibaba Secure payment. Reliable and safe, Alibaba will charge a litter extra fee for the service.

3). Other kinds of payment we can consider if acceptable for us.

2.what's the warranty service?

12 months for all machines and 24 months for motors.

3.How to install and run the machine?

We will send the user's manual and the install video with the machine, you could learn by yourselves, we also provide remote machine training or overseas training services.

4.Do you have matching materials for sale?

Yes,we have all kinds of materials such as aluminum coil, stainless steel, galvanized iron, coppers etc. for sale.

5.How to choose a suitable machine?

You can tell us the working piece material, size, and the machine function request. We can

recommend the most suitable machine according to our experience.

Hot Searches