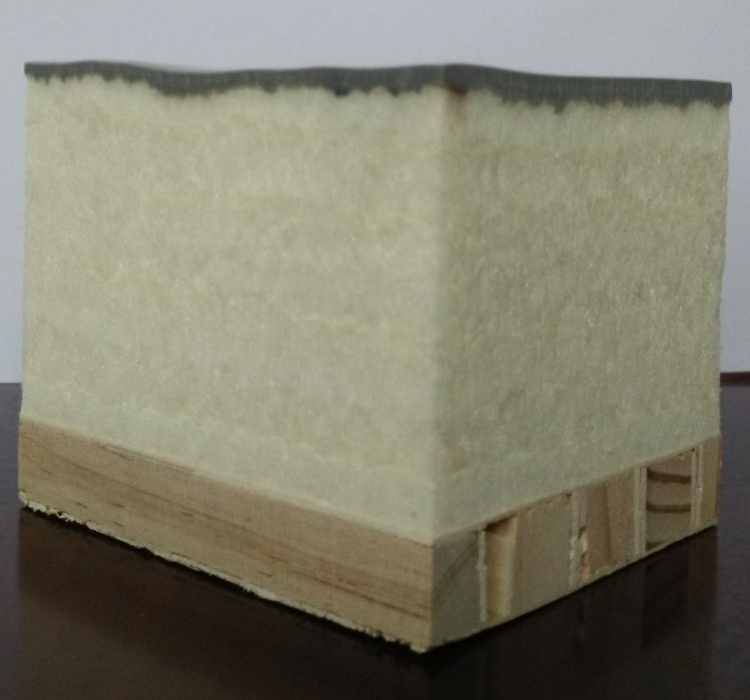

AS2101 / AS2201 is mixed with HCFC-141B blowing agent, which can be rapidly solidified after mixing by spraying machine, which is

suitable for various indoor and outdoor insulation and cooling construction. Material environment matching degree is high, adapt

to various construction environment, odor is small. Foam has good physical properties to meet GB50404-2017. Foam flame retardant

performance is good. Oxygen index will be available according to clients' requirement, which can reach more than 30% for B1 grade

retardant.

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Warehouse

-

Design Style:

-

Traditional

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Aonuo

-

Model Number:

-

AS2101/2102

-

Type:

-

mixture

-

Material:

-

liquid

-

Product name:

-

Closed cell polyurethane thermal foam insulation rigid PU foam

-

Flame Retardance:

-

B1, B2, or B3

-

Free foam Density:

-

25--45 kg/m3

-

Percentage of Close Area:

-

>95%

-

Thermal Conductivity:

-

<0.024w/(m.k)

-

Molding foam density:

-

30--55 kg/m3

-

Specific density:

-

1.14 to 1.24 g/cm3

Quick Details

-

Warranty:

-

NONE

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

NONE

-

Application:

-

Warehouse

-

Design Style:

-

Traditional

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Aonuo

-

Model Number:

-

AS2101/2102

-

Type:

-

mixture

-

Material:

-

liquid

-

Product name:

-

Closed cell polyurethane thermal foam insulation rigid PU foam

-

Flame Retardance:

-

B1, B2, or B3

-

Free foam Density:

-

25--45 kg/m3

-

Percentage of Close Area:

-

>95%

-

Thermal Conductivity:

-

<0.024w/(m.k)

-

Molding foam density:

-

30--55 kg/m3

-

Specific density:

-

1.14 to 1.24 g/cm3

Product Description

Specification

|

Model

|

AS 2101

|

AS2201

|

|

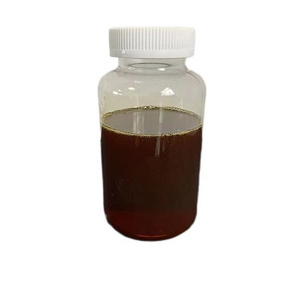

Appearance

|

Colorless to yellowish liquid

|

Colorless to yellowish liquid

|

|

Blowing agent

|

HCFC-141B

|

HCFC-141B

|

|

POL: ISO

|

100:100-130

|

100:100-130

|

|

Temperature ℃

|

12-20

|

12-20

|

|

Cream time, S

|

2-5

|

2-5

|

|

Gel time, S

|

6-10

|

6-10

|

|

Free foam density, kg/m3

|

25-45

|

25-45

|

|

Molding foam density, kg/m3

|

30-55

|

30-55

|

|

Dimensional stability (-30℃ 24h), %

|

≤2.0

|

≤2.0

|

|

Thermal conductivity at 15℃ (W/m.K)

|

≤0.024

|

≤0.024

|

Packing & Delivery

Packaging of galvanized steel barrels with net weight of 220 kg or 200 kg per barrel for B component, 250 kg per barrel for A component, available in ton, container or car tank if required.

Storage and transportation should pay attention to ventilation, cool, dry, avoid sun, rain, away from water, heat source. Long storage, and temperature higher than 60 °C will affect the product quality, short-term heating or cooling has little effect on product quality.

This product belongs to non-flammable explosives.

The shelf life of the product is six months under proper storage conditions.

Storage and transportation should pay attention to ventilation, cool, dry, avoid sun, rain, away from water, heat source. Long storage, and temperature higher than 60 °C will affect the product quality, short-term heating or cooling has little effect on product quality.

This product belongs to non-flammable explosives.

The shelf life of the product is six months under proper storage conditions.

Hot Searches