- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

customization

-

Weight (T):

-

1 T

-

Power (kW):

-

800

-

Item:

-

induction melting furnace for steel iron aluminum copper

-

Tilting method:

-

hydraulic/ motor

-

Suitable Metal:

-

aluminum copper steel iron

-

Max temperature:

-

1800℃

-

Melting Capacity:

-

100kg-10ton

-

Melting Time:

-

40-50mins

-

Furnace body:

-

steel frame /aluminum frame

-

Temperature control:

-

Digital Display Instrument

-

Duty cycle:

-

24hours with 100% load

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Marketing Type:

-

New Product 2023

-

Brand Name:

-

SMKJ

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

customization

-

Weight (T):

-

1 T

-

Power (kW):

-

800

-

Item:

-

induction melting furnace for steel iron aluminum copper

-

Tilting method:

-

hydraulic/ motor

-

Suitable Metal:

-

aluminum copper steel iron

-

Max temperature:

-

1800℃

-

Melting Capacity:

-

100kg-10ton

-

Melting Time:

-

40-50mins

-

Furnace body:

-

steel frame /aluminum frame

-

Temperature control:

-

Digital Display Instrument

-

Duty cycle:

-

24hours with 100% load

Products Description

Hot Sell 1ton 2ton 5ton 10ton Induction Melting Furnace For Steel Iron Aluminum Copper

Our Steel Frame Hydraulic Tilting Induction Melting Furnace owns a strong steel structure, which can minimize the tilting degree and the deformation during pouring. The coil is completely supported in the steel frame and is connected by the miniature shunt. The structure ensures that the furnace lining will not be mechanically impacted during melting and that the refractory castables at the top and bottom of the furnace are fully supported. An optional furnace cover can ensure the highest efficiency, especially when melting high-temperature metals, the ventilation ring can be used to make the entire melting process safer and more effective.

We also have

Aluminum Frame Induction Melting furnace

, which is an economical small melting furnace

and easy to maintain,

suitable for the beginner who wants to start the foundry business, this furnace usually applied in melting metal from 100kg-5000kg, tilting mechanism adopt the reducer motor tilting which is widely used in aluminum frame furnace.

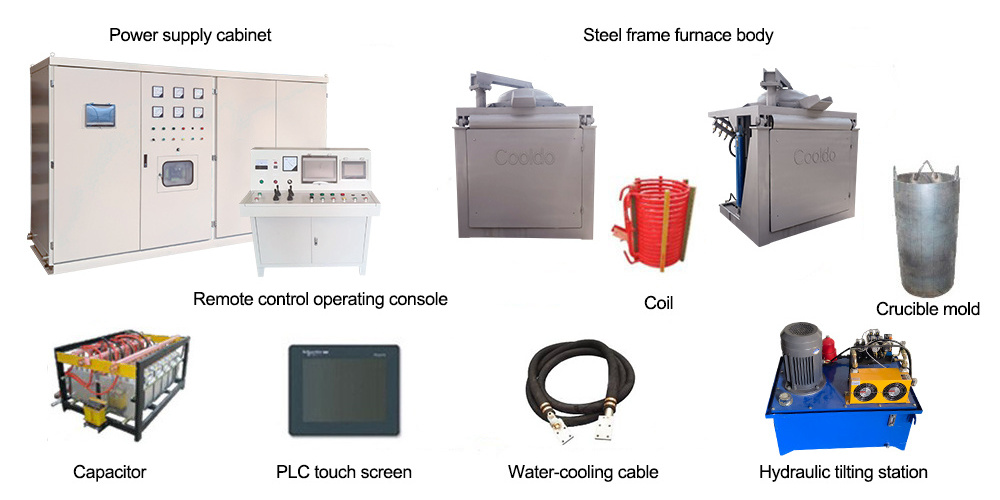

Details Images

Detail description

Power supply cabinet

All the thyristors and diodes in the power cabinet are domestic famous brand silicon tubes. Including rectification and inversion. The power cabinet is made of high-strength cold-rolled steel plate. Open the door to easily access the rectifier and inverter parts. There are lifting hooks above the power cabinet to facilitate transportation and installation.

The copper bar and copper pipe in the power cabinet are made of domestic famous brands.

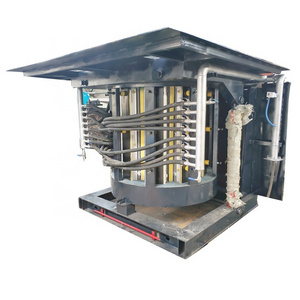

Steel frame furnace body

The steel frame structure is easy for daily maintenance and overhaul. The large-size H-shaped steel or square steel pipe constitutes the basic structure of the furnace frame. The overall structure is simple and solid, and the maximum inclination of the furnace body is 95°. Welded steel structure with appropriate supports and clamps to fix induction furnace coils and yokes; The upper part of the induction furnace can be disassembled, so it is more convenient to replace the coil.

Copper bars

T2 copper bar of electrolytic copper tube is adopted, with a purity of 99.9%.

The copper bar is connected with 1500kW variable frequency power supply and water cooling cable of the furnace body. All the copper bars are cut, formed and assembled in the factory (they may be divided into more than 2 sections for convenient transportation). The standard supply length is 5m for each set.

Induction coil

The induction coil is assembled by solid, durable and highly conductive TU1 oxygen free copper tube. The copper tube of the induction coil is electrolytic copper tube with a purity of 99.9%. The coil is supplied with cooling water by multiple water channels and evenly distributed. The coil is tightly wound with insulating materials. The arc-shaped insulation gasket between turns ensures the uniform coil spacing and is conducive to the discharge of moisture.

Thyristors

The black part is the inverter thyristor converter inductance, which adopts φ 30 T2 copper tube, and the outside is poured with high-temperature resin. It can ensure the consistency, safety and durability of the parallel inductance. It has the advantages of high efficiency, no mechanical noise and wear, fast response, small size, and light weight. It adopts integrated technology of voltage regulation, power regulation, and rectification internally.

Magnet yoke

The yoke is made of high-quality cold-rolled silicon steel sheet with a thickness of 0.27mm. It is uniformly stressed by the rail bolts and provides the maximum pressing force for the coil to ensure the long working life of the furnace lining. The gasket between the yoke and the coil is made of multi-layer high-quality insulating materials, including multi-layer mica plate and multi-layer ceramic fiber plate. The yoke is cooled by water, and the cooling water pipe is made of copper.

Product Paramenters

|

Model

|

Input Voltage (V)

|

Rate Power (KW)

|

Applicable metals

|

Melting capacity (KG)

|

Max temperature (℃)

|

Power Consumption (kWh/t)

|

Hydraulic station (KW)

|

|

GW-0.1/1

|

380

|

100

|

Fe, Cu, Al, etc

|

100

|

1800

|

780

|

1.5

|

|

GW-0.15/1

|

380

|

120

|

Fe, Cu, Al, etc

|

150

|

1800

|

750

|

1.5

|

|

GW-0.25/1

|

380

|

160-200

|

Fe, Cu, Al, etc

|

250

|

1800

|

720

|

2.2

|

|

GW-0.4/1

|

380

|

250-400

|

Fe, Cu, Al, etc

|

400

|

1800

|

700

|

3

|

|

GW-0.5/1

|

380

|

300-500

|

Fe, Cu, Al, etc

|

500

|

1800

|

690

|

4

|

|

GW-0.75/1

|

380

|

400-600

|

Fe, Cu, Al, etc

|

750

|

1800

|

680

|

4

|

|

GW-1.0/1

|

380

|

500-800

|

Fe, Cu, Al, etc

|

1000

|

1800

|

680

|

4

|

|

GW-1.5/0.5

|

380

|

800-1000

|

Fe, Cu, Al, etc

|

1500

|

1800

|

680

|

5.5

|

|

GW-2/0.5

|

380

|

1000-1500

|

Fe, Cu, Al, etc

|

2000

|

1800

|

660

|

5.5

|

|

GW-2.5/0.5

|

380

|

1000-2000

|

Fe, Cu, Al, etc

|

2500

|

1800

|

650

|

7.5

|

|

GW-3/0.5

|

380

|

1500-2500

|

Fe, Cu, Al, etc

|

3000

|

1800

|

650

|

11

|

Customer On-site

Corollary equipment

|

Water cooling tower

Electric furnace coils, yokes, water-cooled cables, and components that carry large currents in power cabinets all require water cooling. The cooling water system is a key system in the intermediate frequency smelting equipment, especially the power cooling system is more critical. Therefore, our company have designed a unique medium frequency water cooling closed circulation system.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Transformer

The transformer is the use of electromagnetic induction principle to change the ac voltage device, the main components are the primary coil, secondary coil and iron core .The main functions are: voltage transformation, current transformation, impedance transformation, isolation, voltage stabilization (magnetic saturation transformer) and so on.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Feature

2. Effectively deal with high-order harmonics, without interfering with surrounding electrical equipment, and without polluting the power grid.

3. Rapid melting and low production cost; low pollution, in line with the national environmental protection requirements.

4. This Induction furnace can be melted directly from the cold furnace, the solution can be completely emptied, and it is

convenient to change the variety of metal to melt.

5. Strong steel structure; which ensures the stable furnace body will not break easily by hitting or the effect of high

temperature.

6. The inner part is equipped with a magnetic shield, which can effectively carry out magnetic shielding, so as to prevent the shell from heating during the smelting process.

7. The high-quality hydraulic cylinder guarantees safety during tilting.

8. Automatic air prop-driven rear guard (flush platform and larger standard design body).

9. Leakage protection device greatly improves safety.

3. Rapid melting and low production cost; low pollution, in line with the national environmental protection requirements.

4. This Induction furnace can be melted directly from the cold furnace, the solution can be completely emptied, and it is

convenient to change the variety of metal to melt.

5. Strong steel structure; which ensures the stable furnace body will not break easily by hitting or the effect of high

temperature.

6. The inner part is equipped with a magnetic shield, which can effectively carry out magnetic shielding, so as to prevent the shell from heating during the smelting process.

7. The high-quality hydraulic cylinder guarantees safety during tilting.

8. Automatic air prop-driven rear guard (flush platform and larger standard design body).

9. Leakage protection device greatly improves safety.

Recommend Products

Packaging & Shipping

Our services

I. Commissioned from the furnace after delivery, into the warranty period, the warranty period of two years.Regardless of the warranty period or warranty period, the furnace, such as failure, received a notice, we are committed to 36 hours to send to the scene to deal with.

II. In the warranty period by our cause failure, we carried out unconditional maintenance and replacement.Due to other causes ofthe failure, we only charge the cost of paid maintenance

III. After the warranty period, we will, as always, do a good job after-sales service, so that users no worries.

I. Commissioned from the furnace after delivery, into the warranty period, the warranty period of two years.Regardless of the warranty period or warranty period, the furnace, such as failure, received a notice, we are committed to 36 hours to send to the scene to deal with.

II. In the warranty period by our cause failure, we carried out unconditional maintenance and replacement.Due to other causes ofthe failure, we only charge the cost of paid maintenance

III. After the warranty period, we will, as always, do a good job after-sales service, so that users no worries.

Customer Photos

FAQ

1. What is your advantage compared to others?

First, we provided turnkey solution, Cost-effective, highly efficient, durable, and easy-to-operate machine is what we deliver.Second, we have a Strict Quality Control System, Before Being dispatched from our factory all of our equipment will undergo a series of strict test, including the appearance quality test, voltage electrical test, aging test also the package strength checking.

2. If our machine meets fault, how could you help us to solve it?

For failures caused by using process, we will send our aftersales engineer to discuss with you, and you should provide the video of how the machine is broken, we will find out which part of the machine is broken, and then we will send you the broken part By DHL.

3. What is your warranty?

Our warranty period comes from the machine begin to run normally and we will provide the whole life technology support to you for free.

All products sold by COOLDO In the warranty period, we will provide you the spare parts for free. Our engineer will help you do the aftersales through our remote control system. When out of one year warranty time, we will provide the spare parts with the cost price for the whole machine lifetime.

First, we provided turnkey solution, Cost-effective, highly efficient, durable, and easy-to-operate machine is what we deliver.Second, we have a Strict Quality Control System, Before Being dispatched from our factory all of our equipment will undergo a series of strict test, including the appearance quality test, voltage electrical test, aging test also the package strength checking.

2. If our machine meets fault, how could you help us to solve it?

For failures caused by using process, we will send our aftersales engineer to discuss with you, and you should provide the video of how the machine is broken, we will find out which part of the machine is broken, and then we will send you the broken part By DHL.

3. What is your warranty?

Our warranty period comes from the machine begin to run normally and we will provide the whole life technology support to you for free.

All products sold by COOLDO In the warranty period, we will provide you the spare parts for free. Our engineer will help you do the aftersales through our remote control system. When out of one year warranty time, we will provide the spare parts with the cost price for the whole machine lifetime.

Hot Searches