- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Yulong

-

Model Number:

-

YL-FR-8

-

Surface Treatment:

-

threaded

-

Keywords:

-

fiberglass rebar

-

Product name:

-

straight and bended fiberglass rebar

-

Other name:

-

BFRP Rebar

-

Name:

-

Customized fiberglass rebar

-

Length:

-

Specific Length Required

-

Quality:

-

Guarantee

-

Material:

-

Fiberglass Yarn + Polymey Resin

-

Color:

-

Customized Colors

-

Feature:

-

Corrosion Resistance

-

Advantage:

-

Higher Strength Light Weight

Quick Details

-

Application:

-

Construction

-

Technique:

-

FRP Continuous Production

-

Place of Origin:

-

China

-

Brand Name:

-

Yulong

-

Model Number:

-

YL-FR-8

-

Surface Treatment:

-

threaded

-

Keywords:

-

fiberglass rebar

-

Product name:

-

straight and bended fiberglass rebar

-

Other name:

-

BFRP Rebar

-

Name:

-

Customized fiberglass rebar

-

Length:

-

Specific Length Required

-

Quality:

-

Guarantee

-

Material:

-

Fiberglass Yarn + Polymey Resin

-

Color:

-

Customized Colors

-

Feature:

-

Corrosion Resistance

-

Advantage:

-

Higher Strength Light Weight

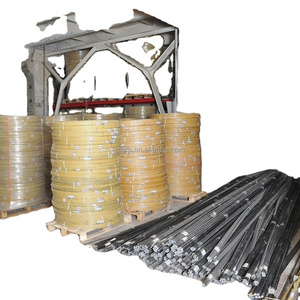

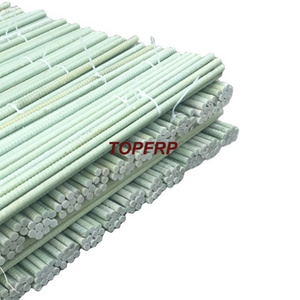

China factory good price Easy maintenance high strength Fiber Glass Reinforced Polymer rebar

What are the featurs of (GFRP) fiberglass rebar?

Pultrusion GFRP Rebar Applied to Concrete exposed to de-icing salts in

Concrete (GFRP) Fiberglass rebar Features

- High strength & light weight

- Long service life

- Fire retardant

- Impact resistant

- Nonconductive and thermal insulation

- Non-magnetic electromagnetic transparency

- Dimensional stability, Bright color

- Low-maintenance

- Corrosion resistant

Concrete (GFRP) Fiberglass rebar Pultrusion Technique:

During the pultrusion process, the raw materials are pulled through a heated steel forming die using a continuous pulling device. FRP Pultruded Profile are made of different resins reinforced with fiberglass, by pultrusion technology.

Concrete (GFRP) Fiberglass rebar Physical Property:

|

Pultruded GFRP(fiberglass) Rebar |

|

|

Place of Origin: |

Hubei, China |

|

Brand Name: |

Yulong |

|

Dimension(mm): |

Customized dimension & colors are both available. |

|

Raw Materials: |

|

|

Color: |

Grey, Blue, Yellow, Red, other customized colors |

|

Diameter /mm |

Cross Section/cm2 |

Weight Kg/m |

Ultimate Tensile Strength/MPa |

Ultimate Shearing Strength/MPa |

E-Modulus/GPa |

|

4 |

0.12 |

0.032 |

1500 |

>150 |

>40 |

|

6 |

0.28 |

0.051 |

1280 |

>150 |

>40 |

|

8 |

0.50 |

0.098 |

1080 |

>150 |

>40 |

|

10 |

0.73 |

0.150 |

980 |

>150 |

>40 |

|

12 |

1.03 |

0.210 |

870 |

>150 |

>40 |

|

14 |

1.34 |

0.275 |

764 |

>150 |

>40 |

|

16 |

1.80 |

0.388 |

752 |

>150 |

>40 |

|

18 |

2.48 |

0.485 |

744 |

>150 |

>40 |

|

20 |

2.78 |

0.570 |

716 |

>150 |

>40 |

|

22 |

3.55 |

0.700 |

695 |

>150 |

>40 |

|

25 |

4.78 |

0.970 |

675 |

>150 |

>40 |

|

28 |

5.90 |

1.195 |

702 |

>150 |

>40 |

|

30 |

6.71 |

1.350 |

637 |

>150 |

>40 |

|

32 |

7.40 |

1.520 |

626 |

>150 |

>40 |

C oncrete (GFRP) Fiberglass rebar Application:

1) Architectural Concrete: cast stone, architectural cladding, balusters, column facades, window lentils, architectural precast elements, hand railing, and statuary and fountains, etc.

2) Concrete exposed to de-icing salts in: bridge decks, railroad grade crossings, median barriers, parking garage elements, and salt storage facilities, etc.

3) Concrete exposed to marine salts in: seawalls, water breaks, buildings & structures near waterfront, aquaculture operations, and floating marine docks, etc.

4) Applications Subjected to Other Corrosive Agents: Wastewater treatment plants; petrochemical plants; pulp/paper mills; liquid gas plants; pipelines / tanks for fossil fuel; cooling towers; chimneys; mining operations of various types; nuclear power and dump plants.

5) Applications Requiring Low Electric Conductivity or Electromagnetic Neutrality: Aluminum and copper smelting plants; manholes for electrical and telephone communication equipment; bases for transmission / telecommunication towers; airport control towers; magnetic resonance imaging in hospitals; railroad crossing sites, and specialized military structures.

Co ncrete (GFRP) Fiberglass rebar Pictures:

What is the Pakage and Shipping details ?

|

MOQ: |

1*20ft |

|

Price: |

EXW, FOB, CNF, CIF |

|

Port: |

Main Port of China |

|

Packaging Details: |

Plywood pallet with plastic wrapped for packing |

|

Delivery Time: |

About 5-10 days after deposit received |

|

Payment Terms: |

TT,L/C, Western Union, Money Gram |

|

Supply Ability: |

6000m/week |

Free sample is available for quality evaluation!