- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

eversun

-

Product Name:

-

Putty Powder Bulk Bag Unloading Machine

-

Application:

-

Industrial Filed

-

Type:

-

Atuomatic

-

Usage:

-

Conveying Products

-

Key Words:

-

conveying Equipment

-

Capacity:

-

Customized

-

Material:

-

Carbon Steel/Stainless Steel 304/316L

-

Color:

-

Customized Color

-

Load capacity:

-

1t - 300t

-

Function:

-

Conveying Goods

Quick Details

-

Warranty:

-

1 Year

-

Weight (KG):

-

100

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

eversun

-

Product Name:

-

Putty Powder Bulk Bag Unloading Machine

-

Application:

-

Industrial Filed

-

Type:

-

Atuomatic

-

Usage:

-

Conveying Products

-

Key Words:

-

conveying Equipment

-

Capacity:

-

Customized

-

Material:

-

Carbon Steel/Stainless Steel 304/316L

-

Color:

-

Customized Color

-

Load capacity:

-

1t - 300t

-

Function:

-

Conveying Goods

Products Description

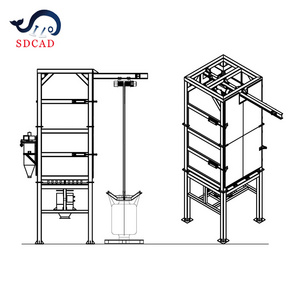

Bulk bag unloading station

Product description of bulk bag unloader

Bulk bag unloading station is composed of a ton bag unpacking machine and a conveyor.

The ton unpacking machine is mainly suitable for 500KG-2000KG packaging powder material disassembly and unloading, and is widely used in chemical, plastics, sewage treatment, infrastructure and other industries. After unpacking the ton package unpacking machine, it can be transported to the right position through pipeline chain conveyor, screw conveyor, pneumatic conveyor system and other conveying equipment to achieve dust-free unpacking and transportation. It not only improves the efficiency of unpacking and transportation, but also solves the problem of dust leakage in dust unpacking transportation, becoming a chemical, pharmaceutical, Optional unpacking and conveying systems for coal, building materials and other industries.

Bulk bag unloading station is composed of a ton bag unpacking machine and a conveyor.

The ton unpacking machine is mainly suitable for 500KG-2000KG packaging powder material disassembly and unloading, and is widely used in chemical, plastics, sewage treatment, infrastructure and other industries. After unpacking the ton package unpacking machine, it can be transported to the right position through pipeline chain conveyor, screw conveyor, pneumatic conveyor system and other conveying equipment to achieve dust-free unpacking and transportation. It not only improves the efficiency of unpacking and transportation, but also solves the problem of dust leakage in dust unpacking transportation, becoming a chemical, pharmaceutical, Optional unpacking and conveying systems for coal, building materials and other industries.

Product advantages of bulk bag unloader

1.Simple structure and high degree of automation improve production efficiency and reduce

labor intensity.

2.The supply is smooth, and the racket rod can ensure the supply of materials.

3.The dust-free closed system ensures that there is no dust leakage during the work process and improves the working environment.

4.Prevent dust from unpacking and feeding, reduce material and energy consumption;

5.reduce labor intensity and play a double protection role for the environment and operators;

6.suitable for unpacking and transportation of large bags of materials.

labor intensity.

2.The supply is smooth, and the racket rod can ensure the supply of materials.

3.The dust-free closed system ensures that there is no dust leakage during the work process and improves the working environment.

4.Prevent dust from unpacking and feeding, reduce material and energy consumption;

5.reduce labor intensity and play a double protection role for the environment and operators;

6.suitable for unpacking and transportation of large bags of materials.

Functional features

1.bag opening speed, high efficiency. TCD1000 large bag feeding is used for material with good fluidity, feeding speed is 5-10bags /H (1 ton bag).

2.Good dust control effect. The equipment adopts a fully enclosed structure to realize synchronous dust collection. During the work of the feeding station, the naked eye can not see any dust leakage. The working environment indicators meet the requirements of the labor health standard.

3. After the bag is inverted, the material is provided with vacuum transportation or pipe chain conveyor to formulate the storage device (material point).

1.bag opening speed, high efficiency. TCD1000 large bag feeding is used for material with good fluidity, feeding speed is 5-10bags /H (1 ton bag).

2.Good dust control effect. The equipment adopts a fully enclosed structure to realize synchronous dust collection. During the work of the feeding station, the naked eye can not see any dust leakage. The working environment indicators meet the requirements of the labor health standard.

3. After the bag is inverted, the material is provided with vacuum transportation or pipe chain conveyor to formulate the storage device (material point).

Product Shows

Details Images

Application

Product packaging

Hot Searches