The working principle of the equipment is: non-direct contact freezing of low-temperature gas (liquid nitrogen) of frozen goods,

put fresh food (seafood, meat, pasta) packed or unpacked into a quick-freezer, and put liquid nitrogen The temperature in the

freezer is quickly reduced to -100 ° (the temperature can be set according to different ingredients, and the lowest temperature

can reach -196 °), and then frozen in a short time. Avoid the ice crystal formation period inside the food to ensure that the cell

tissue will not be damaged, and the nutrients will not be lost after thawing, and the original flavor, taste and nutritional value

will be maintained.

- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Liquid nitrogen quick freezing machine

-

Material:

-

SS304

-

Freezer Type:

-

Liquid Nitrogen Evaporation Freezing

-

Freezing time:

-

Adjusted for different products

-

Capacity:

-

50kg/h

-

lowest Temperature:

-

-196°c

-

Feature:

-

quick freeze

-

feature 2:

-

No loss of nutrients after thawing, maintaining original flavor

-

Color:

-

Silver

-

Application:

-

Seafood, meat, pasta, etc.

Quick Details

-

Voltage:

-

220v/380v

-

Power:

-

0.55kw

-

Cooling Capacity:

-

50kg/h

-

Product name:

-

Liquid nitrogen quick freezing machine

-

Material:

-

SS304

-

Freezer Type:

-

Liquid Nitrogen Evaporation Freezing

-

Freezing time:

-

Adjusted for different products

-

Capacity:

-

50kg/h

-

lowest Temperature:

-

-196°c

-

Feature:

-

quick freeze

-

feature 2:

-

No loss of nutrients after thawing, maintaining original flavor

-

Color:

-

Silver

-

Application:

-

Seafood, meat, pasta, etc.

Product Description

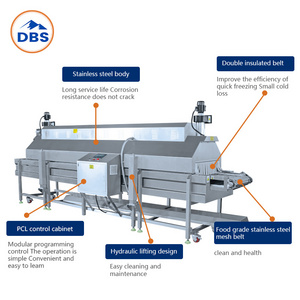

The quick-freezing equipment produced by our company is an energy-saving,

environmentally-friendly, highly efficient and multi-purpose quick-freezing equipment. The use of advanced technology has solved

the problem of uneven ice crystals in the freezing process of seafood, aquatic products, dumplings, buns, and meat foods, and

reached an advanced level in food processing. For example, when the prawn meat is generally frozen, the meat becomes loose when

thawed and loses its original umami. The liquid nitrogen quick-freezer produced by our company is used for freezing. After

thawing, the quality can be guaranteed to be fresh. The machine has a small footprint and is easy to operate.

environmentally-friendly, highly efficient and multi-purpose quick-freezing equipment. The use of advanced technology has solved

the problem of uneven ice crystals in the freezing process of seafood, aquatic products, dumplings, buns, and meat foods, and

reached an advanced level in food processing. For example, when the prawn meat is generally frozen, the meat becomes loose when

thawed and loses its original umami. The liquid nitrogen quick-freezer produced by our company is used for freezing. After

thawing, the quality can be guaranteed to be fresh. The machine has a small footprint and is easy to operate.

|

Model

|

YDSD-200

|

YDSD-400

|

YDSD-800

|

|

Material

|

SUS#304

|

SUS#304

|

SUS#304

|

|

Dimension

|

1.5*1.2*1.1m

|

1.35*1.3*2.0m

|

1.6*1.4*2.0m

|

|

Capacity

|

50kg/h

|

100kg/h

|

200kg/h

|

|

power

|

0.55kw

|

0.75kw

|

1.5kw

|

|

Voltage

|

220v/380v

|

220v/380v

|

220v/380v

|

Working principle of liquid nitrogen quick freezer

Liquid nitrogen quick freezer system composition:

1. Liquid nitrogen host:

The touch screen + PLC control method is used to monitor the temperature change in the box in real time, with automatic operation function, simple operation, high reliability, and automatic alarm when the insulation is over. The all-stainless steel machine is

beautiful and durable, and the thick insulation layer design reduces the waste of cooling to a greater extent. The temperature can be adjusted according to different products.

The touch screen + PLC control method is used to monitor the temperature change in the box in real time, with automatic operation function, simple operation, high reliability, and automatic alarm when the insulation is over. The all-stainless steel machine is

beautiful and durable, and the thick insulation layer design reduces the waste of cooling to a greater extent. The temperature can be adjusted according to different products.

2. Liquid nitrogen tank:

Users need purchase the tank at local place or lease from the nearest gas company

Users need purchase the tank at local place or lease from the nearest gas company

3. Product shelf:

Fully consider the cold air flow passage, so that all products are frozen uniformly

Fully consider the cold air flow passage, so that all products are frozen uniformly

4. Control System:

Model

PLC automatic electrical control system

Model

PLC automatic electrical control system

Working Performance

Related Products

Company Introduction

Zhengzhou iMaker Machinery CO.,LTD is specialized in chocolate machine,baking machine, flour machine ,snack machine ,fruit and vegetable processing machine,Refrigeration machine, meat machine etc.with well-equipped testing facilities and strong technical force.

Intelligent,Profession ,patience and good aftersale service is our culture!

We welcome new and old customers from all walks of life to contact us for future business relationships

FAQ

Hot Searches