- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V, 220 (V)

-

Power:

-

1.5(Kw), 1.5 (Kw)

-

Dimension(L*W*H):

-

1500*750*1100(mm)

-

Weight:

-

200() ()KG

-

Marketing Type:

-

Hot Product 2022

-

whatsAPP:

-

+8613525551927

-

Dimensions:

-

1500*750*1100 (mm)

-

Net weight:

-

200 (Kg)

-

Packing:

-

wooden frame

-

Scope of application:

-

bakery equipment, casual fast food equipment,

-

Marketing:

-

new products

-

After sales service:

-

one year

Quick Details

-

Production Capacity:

-

200-400kg/H

-

Place of Origin:

-

China

-

Brand Name:

-

hanchuang

-

Voltage:

-

220V, 220 (V)

-

Power:

-

1.5(Kw), 1.5 (Kw)

-

Dimension(L*W*H):

-

1500*750*1100(mm)

-

Weight:

-

200() ()KG

-

Marketing Type:

-

Hot Product 2022

-

whatsAPP:

-

+8613525551927

-

Dimensions:

-

1500*750*1100 (mm)

-

Net weight:

-

200 (Kg)

-

Packing:

-

wooden frame

-

Scope of application:

-

bakery equipment, casual fast food equipment,

-

Marketing:

-

new products

-

After sales service:

-

one year

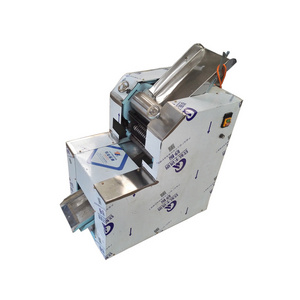

Chin Chin Cutting Machine Chinchin Making Machine

whatsAPP:+8613525551927

Multifunctional dough forming machine:

Multi-function spot forming machine features: high function, high output, labor saving, labor intensity reduction, cost saving, safe and reliable use, and convenient maintenance.

The multi-function noodle forming machine is a multifunctional cutting machine developed by simulating the principle of manual cutting of food. The machine consists of three processes: pressing surface, forming and conveying belt. The operation is simple and the whole process requires only 1-2 people. The width, thickness and thickness of the honey horn can be adjusted according to the user, and the size of the honey horn can be cut to the same size without sticking. This machine is widely used in more than 20 varieties of Jiangmi strip, honey three knife, mouth cake, red chrysanthemum cake, green red silk, crisp sugar, open smile, horn honey, small hemp leaf, row fork, honey knife ring, chess pieces, etc. The food cutting process can cut a variety of patterns, such as pieces, blocks, wires, diamonds and curves, and has stepless speed regulation capability, so that you can adjust the field frequency processing size according to your own needs. Suitable for pasta, pastry, pastry processing enterprises

| Type | Brand | Model | Voltage | Power | Dimensions | Net weight | Packing | Marketing |

| Cookware | hanchuang | HC-CC1000 | 220 (V) | 1.5 (Kw) | 1500*750*1100 (mm) | 200 (Kg) | wooden frame | new products |

Product installation:

1. Place the machine in a horizontal work site to ensure that the machine is placed in a stable and reliable manner;

2. Check the parts before use, whether the fasteners are loose during transportation, whether the switch and power cord are damaged due to transportation, and take corresponding measures in time;

3. Check if there is any foreign matter in the rotating barrel, if there is any foreign matter cleaned up, so as to avoid damage to the tool;

4. Make sure the power supply voltage matches the rated voltage of the unit. Reliably ground at the grounding mark of the cover, extend the power cord to a professional electrician, connect the power cord of the machine to the all-pole disconnected large open-distance power supply, turn on the power, press the “ON” button to check the steering, V-belt The steering is consistent with the mark; otherwise the power is turned off and the wiring is adjusted.

5. When the machine is working, it is strictly forbidden to reach into the bucket;

6. Before cleaning and disassembling, first disconnect the power supply to stop the machine;

7. To ensure safety, it must be reliably grounded at the grounding mark;

8. The bearing is replaced with calcium-based grease once every 3 months;

9. Do not press the switch with wet hands during machine operation.

Pre-sale service

1.Related machines’s technical parameter will be supplied to customer.

2.According to customer’s factory size, factory layout can be provided in advance.

3. According to customer’s material cost, general formulation can be prepared well.

4.Special machine can be supplied as customer’s request.

5.Professional Advice about Market, machines, processing , materials, packing can be supplied

6. Suggesting professional ship agent or helping book ship as customer request.

After sale service :

1.Allocation chart as the buyer’s request will be supplied.

2.Operation manual will be supplied after shipment.

3.One year warrantee, life time maintenance with cost price.

4.Free easy broken spare parts will be sent with container .

5.First installation can be done by engineer.

6.Training workers in customer’s factory.

If you had any problem, just feel free to contact with us.

Any time, we will reply you as soon as possible!