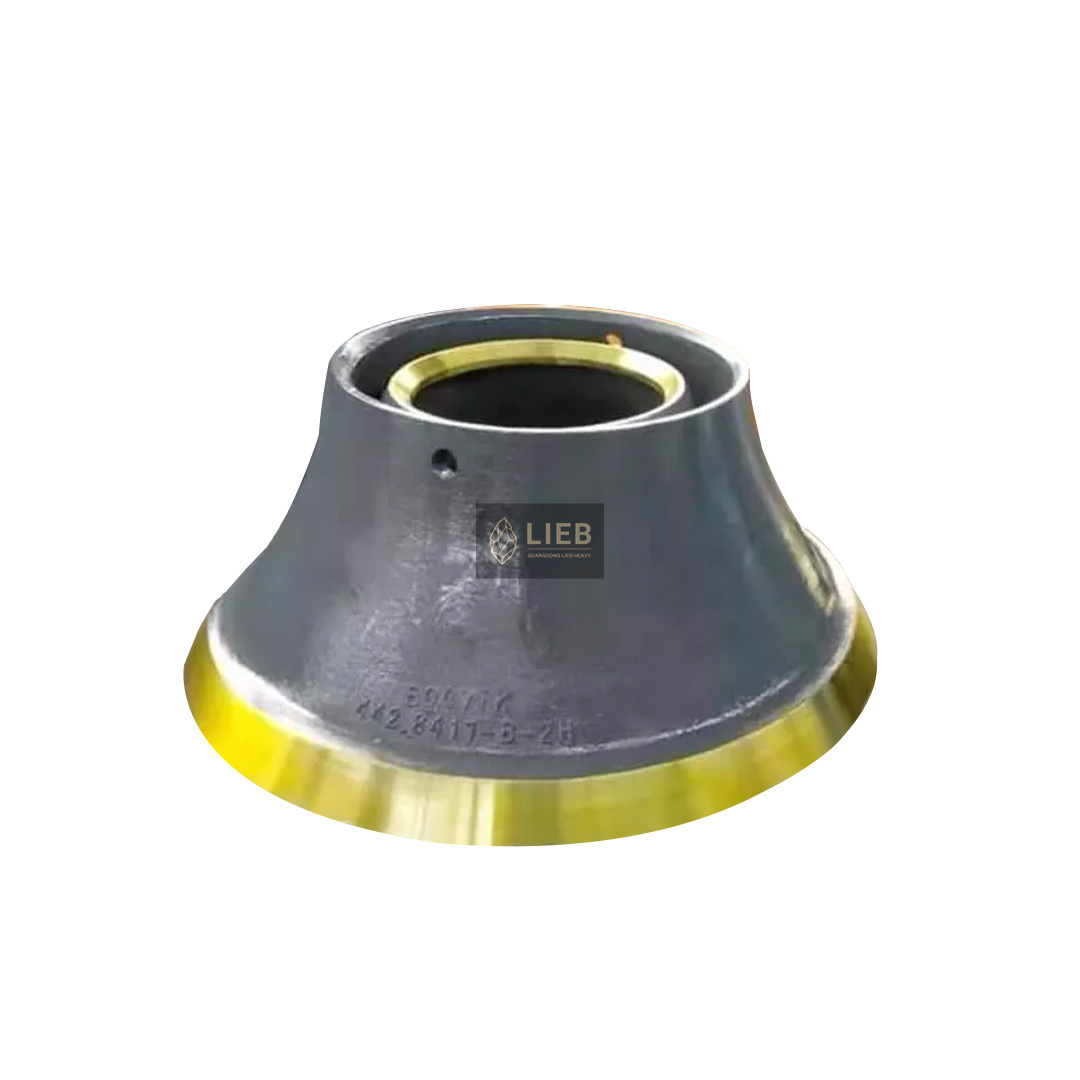

The metallurgy of LiebHeavy standard cone crusher liners range from:

Mn13Cr2, Mn18Cr2 and Mn22Cr2

according to your application.

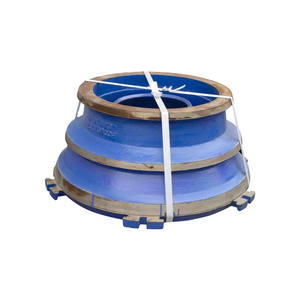

Our massive database and mold inventory ensures that you can get any crushing cavity of most popular cone crushers.

Our massive database and mold inventory ensures that you can get any crushing cavity of most popular cone crushers.