Now it is widely applied in mining, metallurgy,quarry, building waste, smelting,electricity, building material, highway, railway, water conservancy, transportation, chemical industries and other fields.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Fuyuan

-

Dimension(L*W*H):

-

1700*1732*1653

-

Weight:

-

7000 KG

-

Marketing Type:

-

Hot Product

-

Product name:

-

Stone jaw crusher

-

Model:

-

PE400*600

-

Keyword:

-

jaw crusher

-

Color:

-

Customizable

-

The Machines classification:

-

Variety

-

Max feeding size:

-

480mm

-

Motor power:

-

55-75kw

-

Function:

-

Crushing stone

-

Output size:

-

65-160mm

-

Installation:

-

Under Engineer's Guide

Quick Details

-

Application:

-

Stone Crusher

-

Capacity(t/h):

-

90-180t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fuyuan

-

Dimension(L*W*H):

-

1700*1732*1653

-

Weight:

-

7000 KG

-

Marketing Type:

-

Hot Product

-

Product name:

-

Stone jaw crusher

-

Model:

-

PE400*600

-

Keyword:

-

jaw crusher

-

Color:

-

Customizable

-

The Machines classification:

-

Variety

-

Max feeding size:

-

480mm

-

Motor power:

-

55-75kw

-

Function:

-

Crushing stone

-

Output size:

-

65-160mm

-

Installation:

-

Under Engineer's Guide

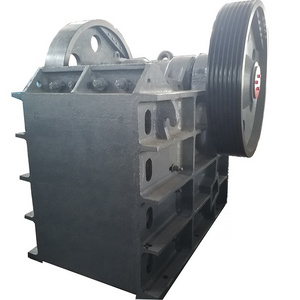

PE400X600 PE 500*750 PE 600*900 Stone Crushing Machine Jaw Crusher

Jaw Crusher

Jaw crusher is combined with the secondary crushing equipment in the whole stone crushing line,like cone crusher and impact crusher. Due to their smaller physical size, jaw crushers are also ideal for tight spaces, such as underground mining and mobile crushing applications.

Product Display

Jaw crushers have proven their reliability and high productivity in thousands of mine, quarry, recycling, and industrial applications. Jaw crushers are specially developed for crushing the hardest ores and rocks, and are particularly good at crushing less hard materials. In addition to stationary jaw crushers, many models are also suitable for mobile or portable crushing stations.

Main Technical Paraments

|

Model

|

Opening size(mm)

|

Max feeding size(mm)

|

Output adjustment range(mm)

|

Production capacit(t/h)

|

|

PE250*400

|

250*400

|

200

|

20-50

|

5-20

|

|

PE400*600

|

400*600

|

350

|

40-100

|

15-60

|

|

PE500*700

|

500*700

|

425

|

50-100

|

40-110

|

|

PE600*900

|

600*900

|

480

|

65-160

|

90-180

|

|

PE750*1060

|

750*1060

|

630

|

80-140

|

110-320

|

|

PE900*1200

|

900*1200

|

750

|

95-165

|

220-450

|

|

PE1200*1500

|

1200*1500

|

1020

|

150-300

|

400-800

|

Stone Crushing Line

Stone Crushing Line

The Stone Crushing Line mainly consists of Vibrating Feeder, Jaw Crusher/Cone Crusher/ Impact Crusher, add vibrating Screen, Belt Conveyor and Control System, etc.It is completely capable to crush and screen limestone, marble, granite, basalt, river gravel and other hard stone materials, suitable for construction and building industry.We can provide optimum and most economical solutions according to your' requirements.

Fuyuan Company is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills,s and mineral beneficiation plants. We can offer you a free design and complete solutions according to your project.

The jaw crusher is mainly used for primary crushing equipment (coarse crusher). It is used extensively throughout the aggregate and mineral processing industry. Also, it is applied in construction material recycling, metallurgy, the chemical industry, electric power, water conservancy, transportation, and other fields. etc.

The jaw crusher can process over 120 kinds of rocks to medium particle size, such as limestone, granite, quartz, basalt, river stone, gold ore, iron ore, coal, gravel, aggregate, etc. Different final output sizes could meet your different needs.

Woking Principle

Working principle of stone jaw crusher motor drives the eccentric axis rotating through the belt pulley, so that the

movable jaw approaches and leaves the fixed jaw cyclical, which makes the materials squeezed, rubbed, multi-roller crusher, etc. so that the materials are crushed into small size, and then decline gradually, at last discharge from the discharging mouth.

Hot Searches