Hemispherical Valve Used in Molten Salt System

-

Transport Package:

-

Wooden Box

-

Specification:

-

DN50~DN500

-

Trademark:

-

Quanshun

- Product Details

- {{item.text}}

Quick Details

-

Origin:

-

Zhengzhou China

-

Media:

-

Other

-

Material:

-

Carbon Steel

-

Connection Form:

-

Flange

-

Driving Mode:

-

Other

-

Nominal Pressure:

-

ANSI CLASS 150-900

-

Channel:

-

Straight Through Type

-

Structure:

-

Fixed Ball Valve

-

Type:

-

Fixed Ball Valve

-

Function:

-

Other

-

Temperature:

-

High Temperature

-

Application:

-

Industrial Usage Water Industrial Usage

-

Applicable Medium:

-

Liquid Kno3,Nano3, Nano2, Mixture

-

Applicable Temperatu:

-

425 Degree.

-

Payment:

-

L/C T/T

-

Export Port:

-

QINGDAO , SHANGHAI, TIANJING

-

Output:

-

300 Sets Per Month

-

Model NO:

-

BQ360Y-16C

Quick Details

-

Applicable Medium:

-

Liquid Kno3,Nano3, Nano2, Mixture

-

Applicable Temperatu:

-

425 Degree.

The hemispherical valve used in molten salt system is a new type of hemispherical valve developed to solve the technical problems of two phase flow medium transportation such as solution and pulp. This product fills a blank of the domestic valve variety, especially suitable for liquid molten salt KNO3, NaNo3 and NaNo2 mixtures, It overcomes the disadvantages of traditional valve, such as easy to scar, easy to jam, easy to leak and short life.,and shows unique advantages.

Product Features

1.The product is novel in structure and adopts eccentric-wedge mechanism to achieve the functions of brake tension, regulation,opening and closing by transmission mechanism.

2.The valve and pipe flange are connected by clamping with four positioning holes, easy to assemble and disassemble.

3.The direct structure has large circulation area, small resistance and low system pressure drop.

4. The design of the valve chamber is streamlined, reducing the resistance of the liquid, and there are measures to prevent scars in various activities and seals.

5.The connection between the stem and the ball adopts a rectangular spline connection with high positioning accuracy and large torque transfer.

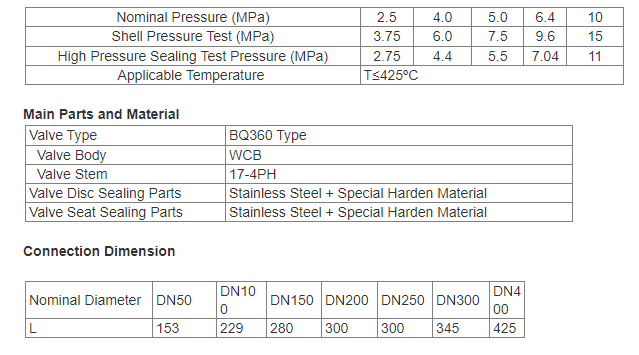

Main Technical Parameters